Spacecraft propellant in-orbit filling system and spacecraft propellant in-orbit filling method

A filling system and spacecraft technology, applied in the field of propellant on-orbit filling system and spacecraft propellant on-orbit filling system, can solve problems such as the complexity of space fluid transmission process, avoid attitude interference torque, and simplify docking Mechanism, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

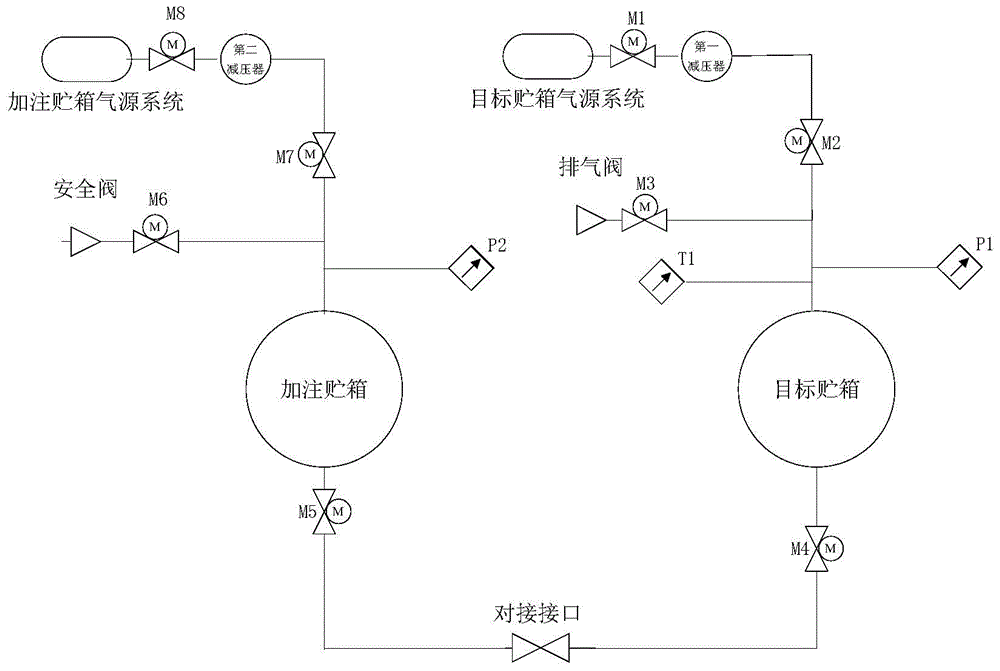

[0017] Based on the research basis of space on-orbit refueling service technology, there are currently three conventional propellant on-orbit replenishment methods: one is direct refueling, the other is module replacement, and the third is module addition. Among them, the direct refueling method has better engineering implementation and has been adopted by Russian and American space missions. This on-orbit refueling method requires that the target spacecraft and the supply spacecraft have corresponding on-orbit supply interfaces and pipeline systems, and will not have a great impact on the overall layout of the spacecraft. At the same time, the system has the characteristics of reusability, and the replenishment spacecraft can perform multiple on-orbit replenishment to multiple targets or to a single target.

[0018] In a microgravity environment, the propellant and pressurized gas inside the tank are in a state of gas-liquid mixing, and it is necessary to discharge a large am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com