Automatic pipe packaging machine

A pipe and automatic technology, applied in the directions of packaging automatic control, packaging, packaging protection, etc., can solve the problems of high labor intensity and low efficiency, and achieve the effect of reducing labor intensity, reducing bumps and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

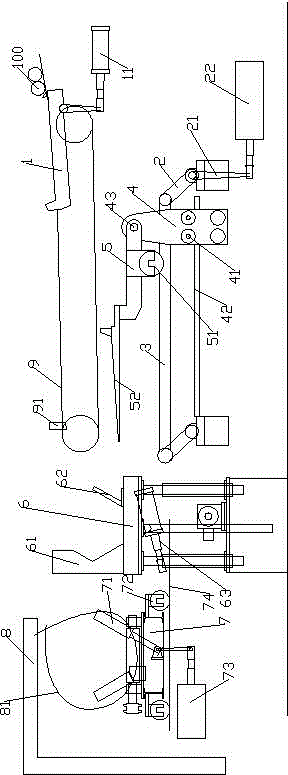

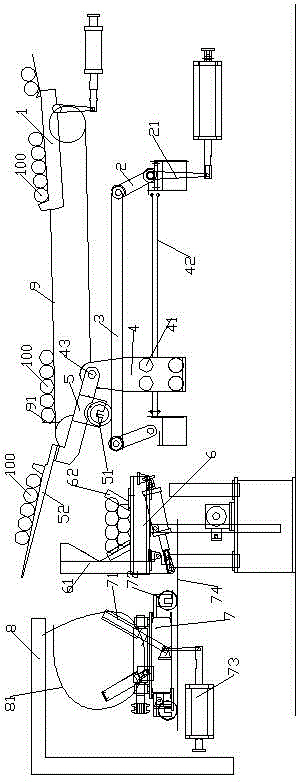

[0018] Illustrate the specific embodiment of the present invention in conjunction with accompanying drawing: comprise counting device, pulley, transport vehicle, stacking device and stacking device and packing device;

[0019] Such as figure 1 As shown, the counting device includes a counter and a counting pallet 1, and the pallet driving device 11 controls the turning of the counting pallet 1; the height of the rollers at both ends of the pulley 9 is different, the pulley 9 is inclined, and the lower end has a pulley baffle 91 The counting pallet 1 is installed on the higher end of the belt pulley 9 and is parallel to the belt pulley 9; the counter counts the number of pipes 100 rolled onto the counting pallet 1 according to the number of pipes required in each layer, and when the preset number is reached, The pallet driving device 11 drives the counting pallet 1 to turn downwards, the pipes on the counting pallet 1 fall onto the pulley 9, and the pipes roll along the pulley ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com