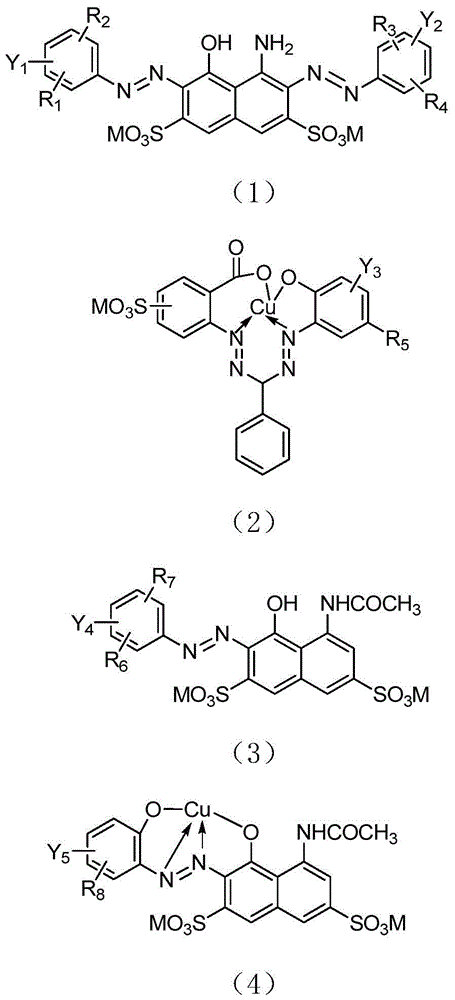

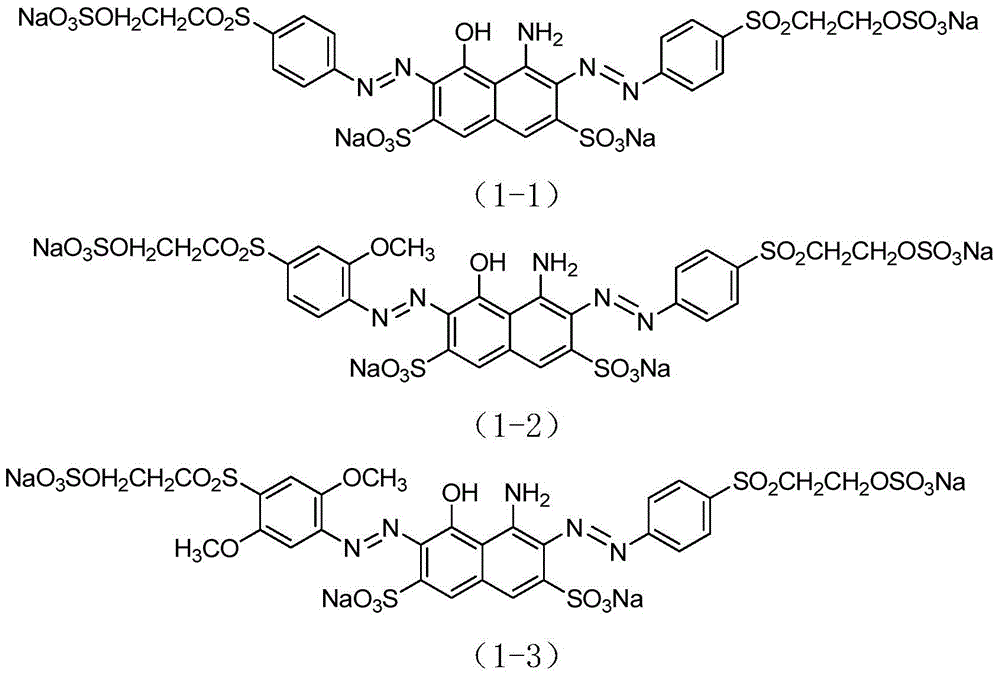

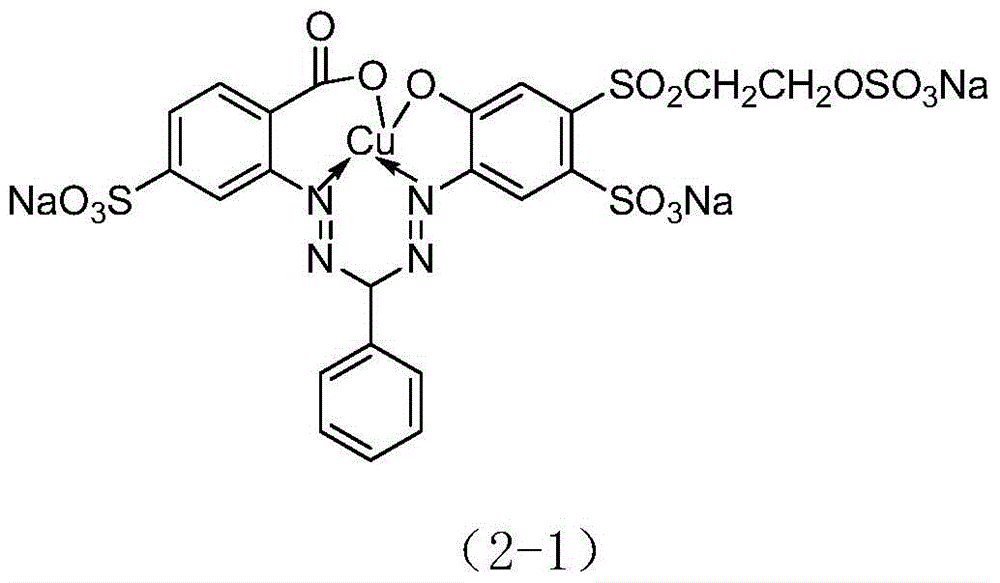

A kind of composite reactive blue dye and its application

A technology of reactive blue and dyes, applied in the field of dyes, can solve the problems of non-dye-resistant printing, discharge printing, difficult process control, and low applicability, and achieve good stability and compatibility, excellent fastness, and low price Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Each reactive dye composition (sample number 1-9) according to the ratio shown in Table 1 was mixed as dry powder in a mixing tank, or spray-dried after dissolving together.

[0040] There are other reactive dye compositions that are not listed one by one, but are included in the present invention.

[0041] Table 1

[0042] serial number

[0043] 2

Embodiment 2

[0045] 10g cotton cloth, the compound reactive blue dye that obtains by embodiment 1 sample sequence number 1-9, configure printing paste: dyestuff 1.5g, urea 5g, water 50g, former paste 25g, resist salt S0.5g, baking soda 1g mix homogeneously . Then the slurry is directly printed, dried, steamed and post-treated on the cotton fabric. The post-treatment of dyed fabrics is washed, soaped and dried. The resulting dyed cotton cloth has uniform color and satisfactory light and wet treatment fastness, and other advantages are also relatively good. See Table 2 and Table 3 for specific performance. Simultaneously, the inventor of the present application has also made the comparative example (table 3) of other 10 blue pigments

[0046] Table 2

[0047]

[0048]

[0049] table 3

[0050]

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com