Multi-stage supercharging exhaust valve

An exhaust valve and high-pressure technology, which is applied in the direction of valve devices, non-mechanically actuated valves, engine components, etc., can solve the problem of invariable exhaust phase and valve lift, large working noise of mechanical transmission mechanism, and easy wear and damage of cams and other issues to achieve flexible exhaust timing and duration angle, improve emissions and fuel economy, and achieve the effect of a large degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

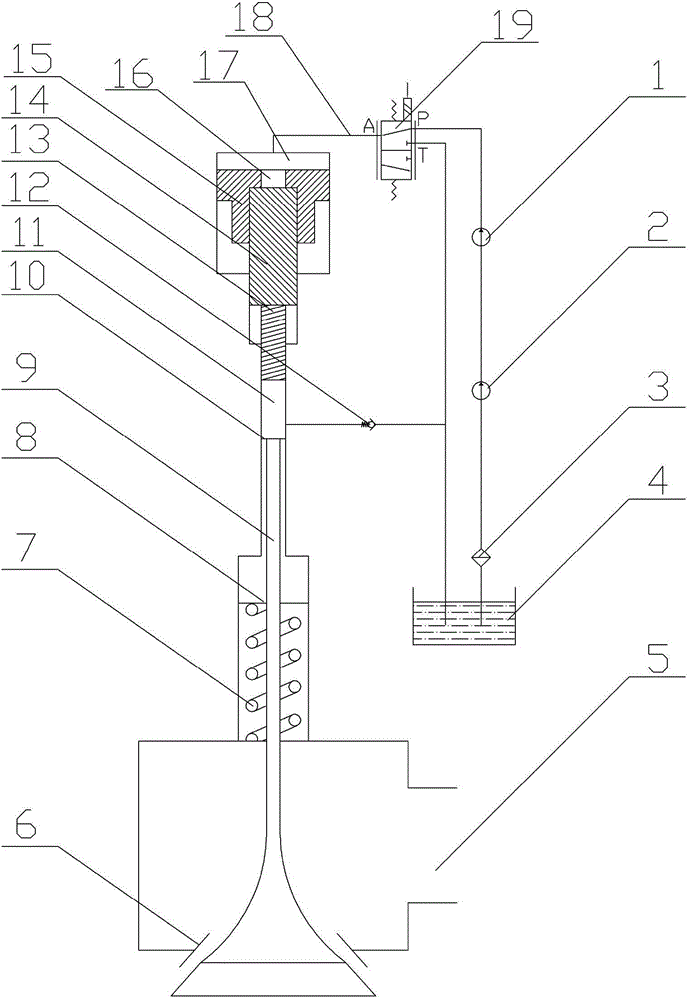

[0012] The present invention is described in more detail below in conjunction with accompanying drawing example:

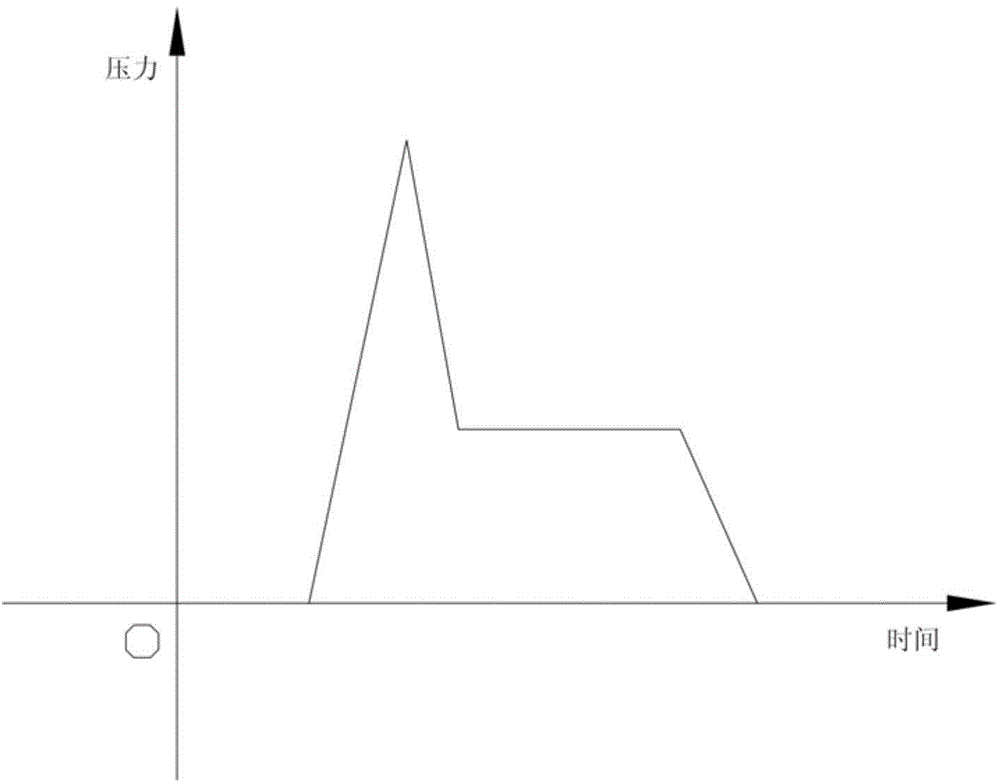

[0013] combine Figure 1~2 , the present invention consists of exhaust valve seat 6, exhaust valve reset spring 7, exhaust valve reset spring seat 8, exhaust valve stem 9, exhaust valve hydraulic piston 10, pressurization chamber 11, hydraulic plunger 13, two The first stage piston 14, the first stage piston 15, the servo oil through hole 16 and the hydraulic chamber 17 are composed. Its features are: a hydraulic cavity 17 is formed between the primary piston 15 and the exhaust valve body, the hydraulic cavity 17 is connected to the high-pressure servo oil pipe 18 through the servo oil inlet, the primary piston 15 is used as the piston sleeve of the secondary piston 14 and the secondary The pistons 14 are connected, and the secondary piston 14 can slide back and forth in the primary piston 15. The primary piston 15 has a servo oil through hole 16, and the servo o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com