Heat pipe and heat exchanger adopting same

A heat pipe and heat exchange part technology is applied in the field of heat pipes and heat exchangers having the heat pipes, which can solve the problems that fluids cannot flow and integrate well, affect heat exchange efficiency, increase heat exchange efficiency, etc., and save production materials. , the effect of improving heat transfer efficiency, increasing porosity and heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

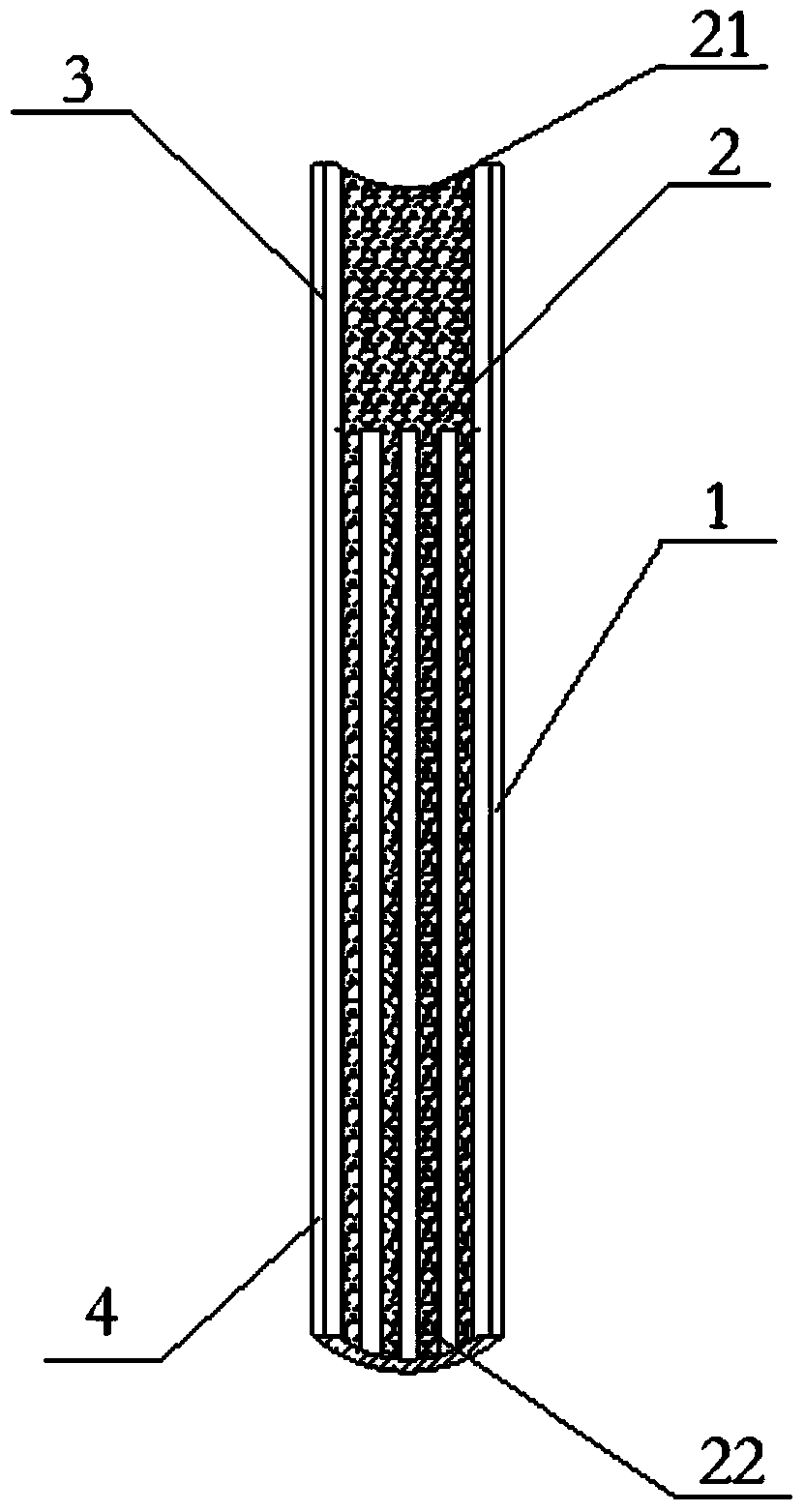

[0029] Such as Figure 1-3 Shown is a heat pipe proposed in this embodiment, which includes a tube body 1 having a flat cross-sectional shape, and two ends of the tube body 1 are respectively an evaporation section 3 and a condensation section 4 . The height between the upper wall and the lower wall of the tubular body 1 is 1.2mm-1.5mm; the width of the tubular body 1 is 8.3mm-8.5mm; the thickness of the upper wall and the lower wall of the tubular body 1 is 0.15mm-0.2mm. As a preferred embodiment, the cross section of the pipe body 1 is an oblong cross section or a rectangular cross section.

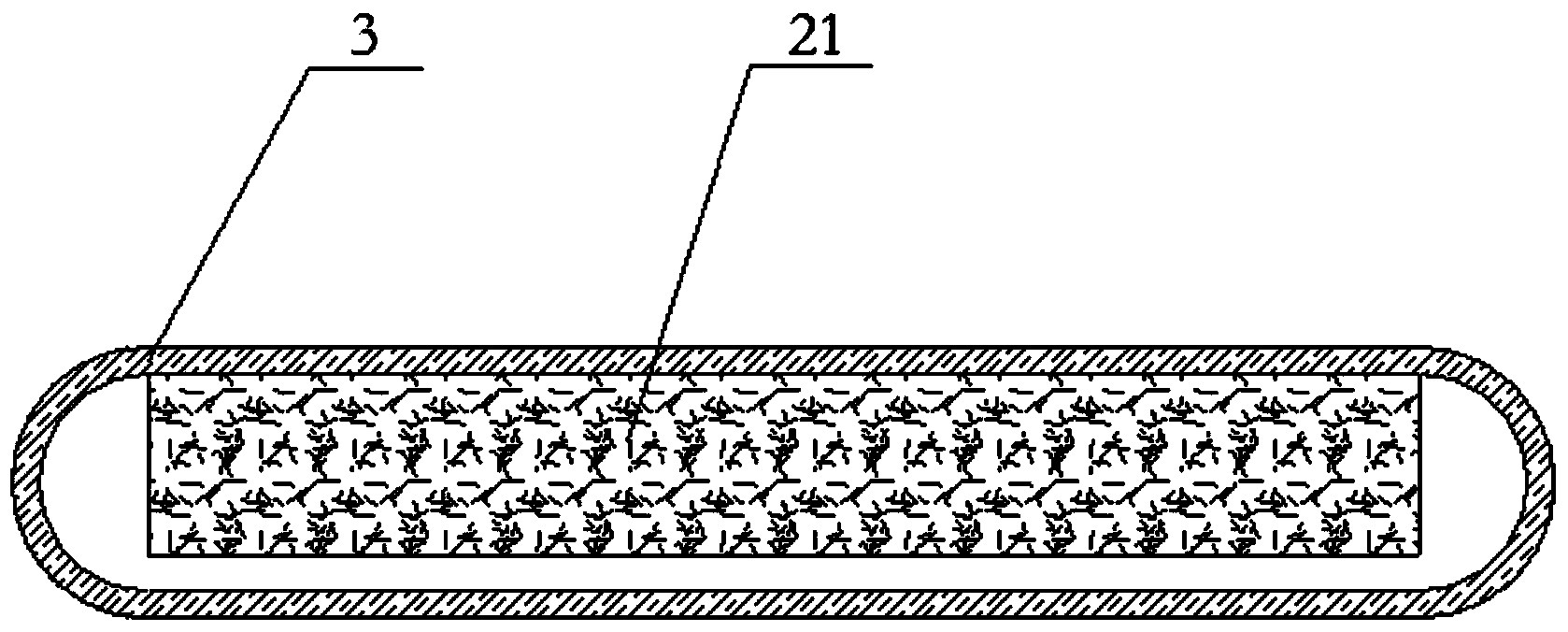

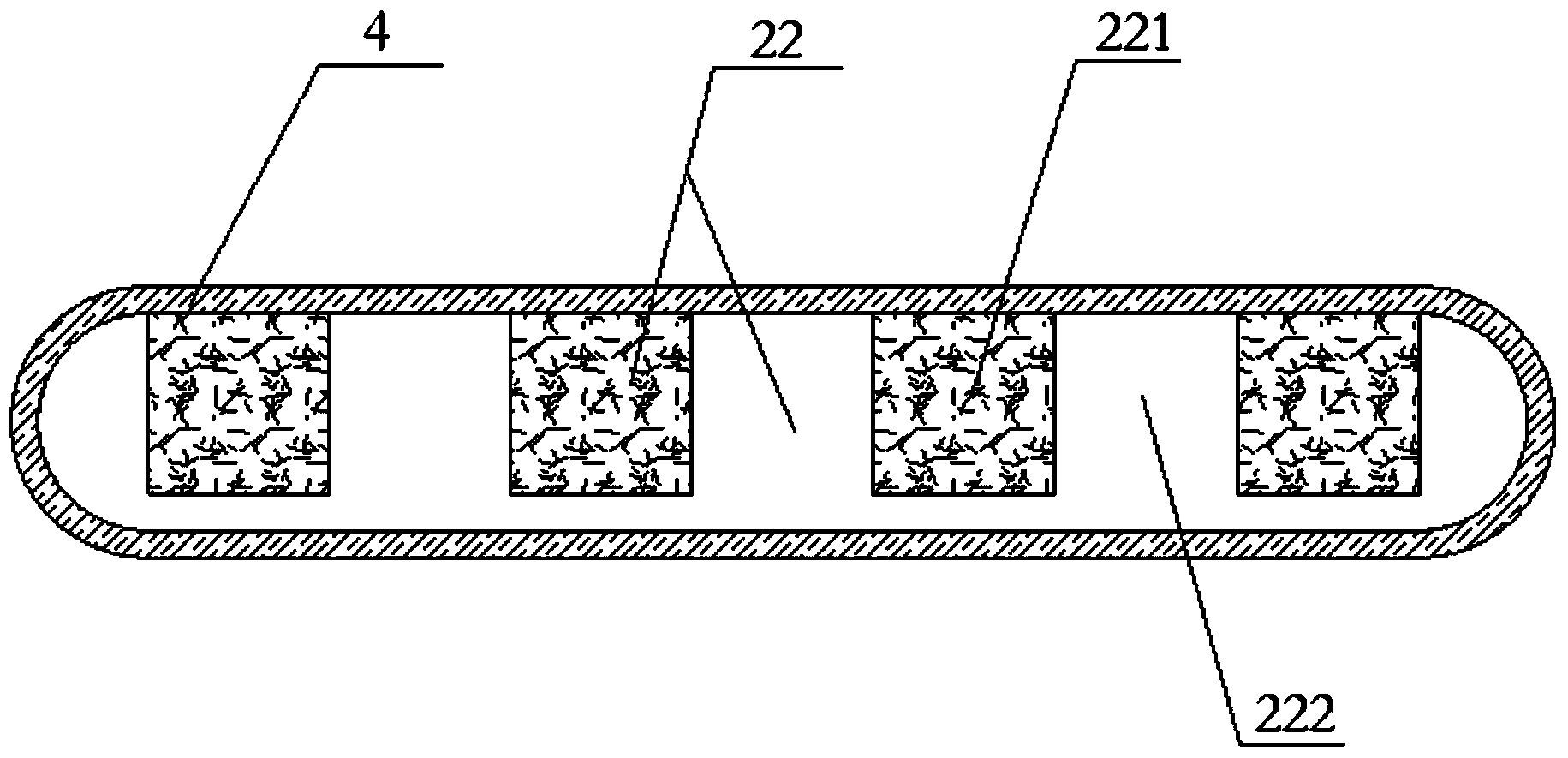

[0030] A sintered capillary structure 2 is provided on the inner surface of the upper or lower wall of the cross section, the sintered capillary structure 2 extends along the axial direction of the tube body 1, and the width of the sintered capillary structure 2 is 5.0mm- 5.5mm. In the process of forming the pipe body 1, copper pipes with an inner diameter of 5 mm, 6 mm or 8 mm and a...

Embodiment 2

[0035] This embodiment proposes a heat exchanger, and the heat pipe as described in Embodiment 1 is arranged inside the heat exchanger. The heat exchanger in this embodiment is made of the heat pipe in Embodiment 1. The heat pipe wall is thinner, which improves the heat transfer efficiency, enhances the heat conductivity of the heat exchanger, and reduces the production cost of the heat exchanger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com