An intelligent methane full-scale sensor and its full-scale methane concentration measurement method

A full-scale sensor, smart methane technology, applied in the field of smart sensors, can solve the problems of shortening the service life of the sensor, not providing a digital communication interface, and no catalytic combustion black components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

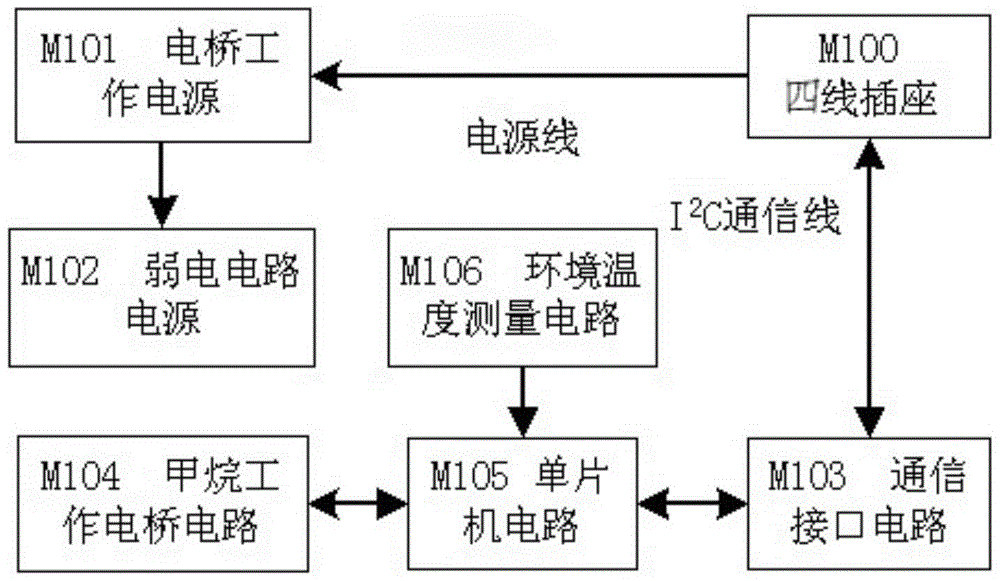

[0031] Such as figure 1As shown, the intelligent methane full-range sensor described in this embodiment includes a four-wire socket M100, a bridge working power supply M101, a weak current circuit power supply M102, a communication interface circuit M103, a methane bridge working circuit M104, a single-chip microcomputer circuit M105 and The ambient temperature measurement circuit M106 used to calculate the temperature rise of the methane detection element relative to the ambient temperature; wherein, the intelligent methane full-range sensor is connected to an external device (transmitter or controller) through a four-wire socket M100; the four-wire socket The two power lines of M100 are connected to the bridge power supply M101, through which the bridge power supply M101 provides a 3.6V power supply to power the bridge circuit, and also supply power to the weak current circu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com