Device and method for ultrasonically measuring flow orientation of polymer melt on line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

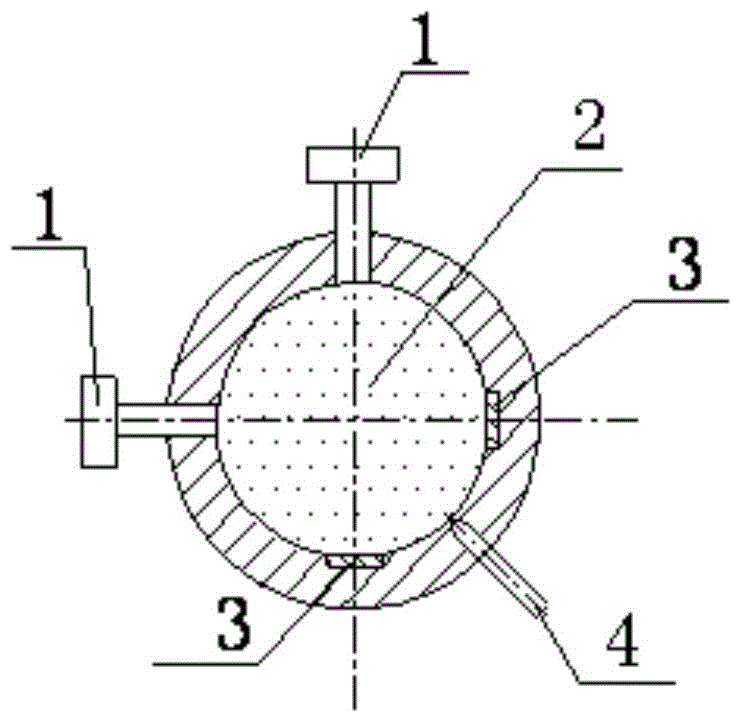

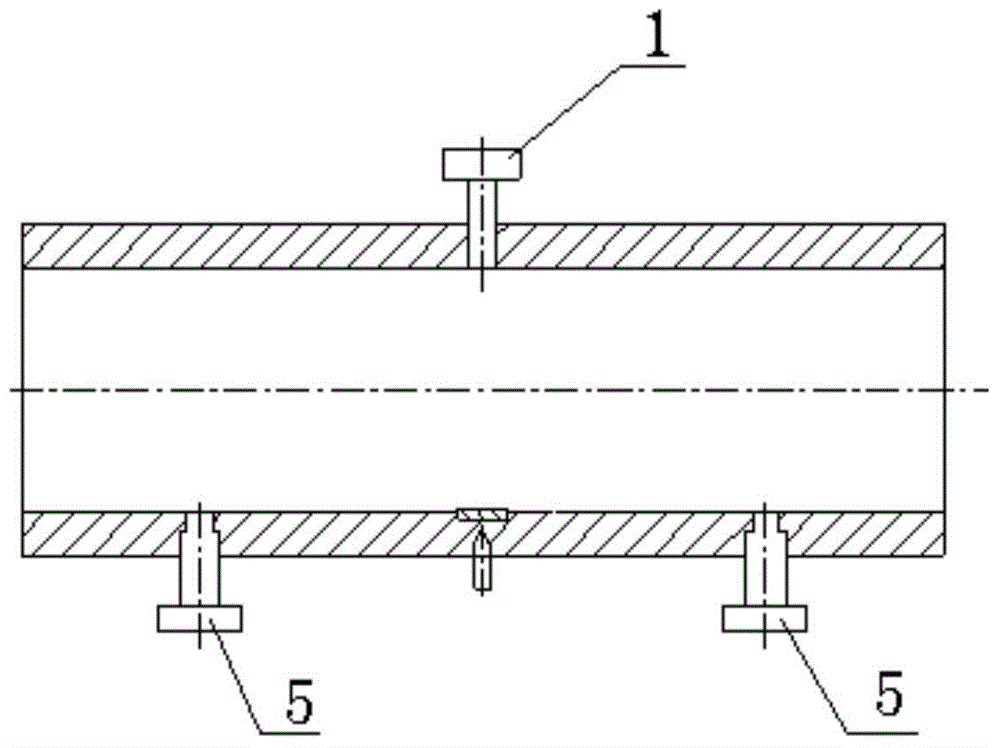

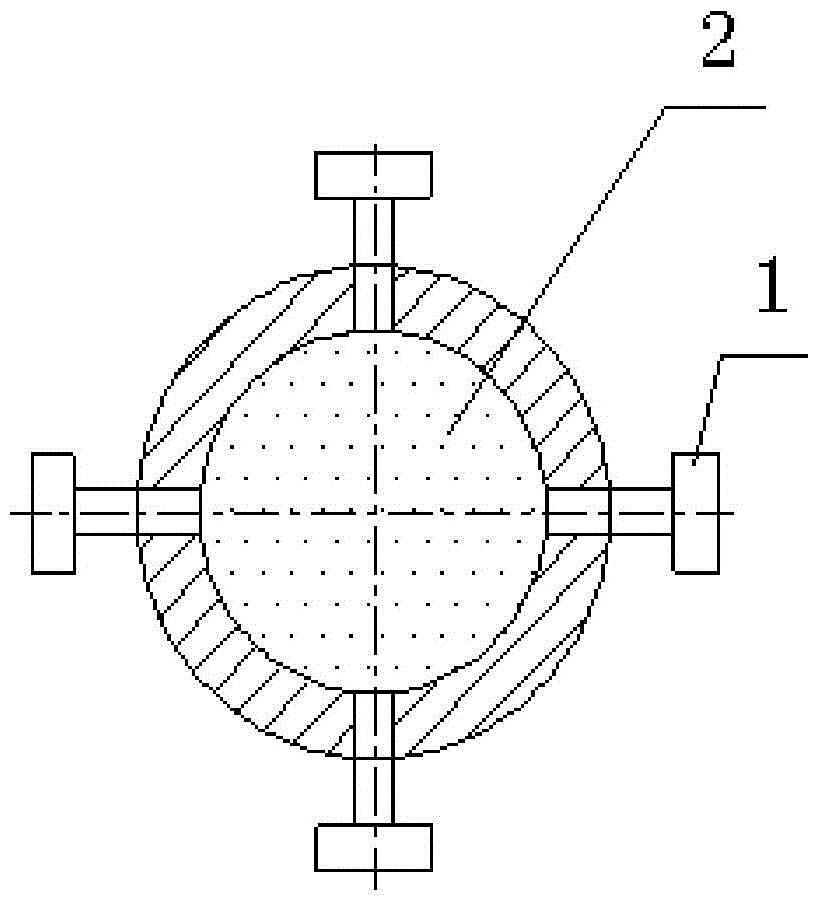

[0034] Such as Figures 1 to 7 shown. The invention discloses a device for ultrasonic on-line measurement of polymer melt flow orientation, the orientation device includes a signal processing center (see Figure 7 ), an ultrasonic transducer 1 for transmitting and receiving ultrasonic signals; the signal processing center is connected to the ultrasonic transducer 1; there are at least two ultrasonic transducers 1, and they are installed in the polymer material molding, melt flow through channel 2.

[0035] The melt flow channel 2 (ie, the test section) has a circular cross-section. The circular cross-section reduces the anisotropy caused by the non-uniform melt flow field caused by the asymmetry of the runner.

[0036] At least two ultrasonic transducers 1 are fixedly installed on the cross section perpendicular to the melt flow channel 2 (including multiple ultrasonic transducers installed on the same section of the melt flow channel 2 or vertically installed on the melt f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com