Waveguide array antenna high-power performance testing apparatus

A technology of waveguide array and testing device, which is applied in the field of high-power performance testing device of waveguide array antenna, and can solve problems such as low antenna, gas breakdown of antenna unit, and influence on physical experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

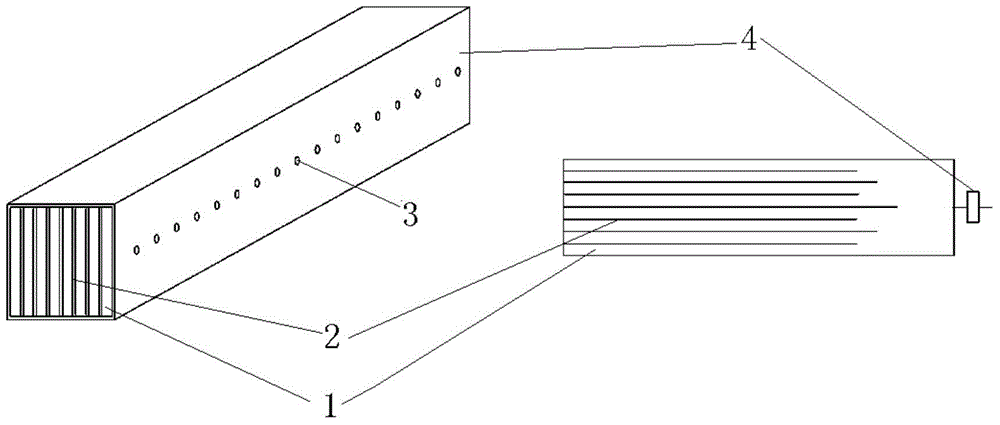

[0015] The antenna unit will emit a large amount of gas during the experiment. In order to transfer the gas molecules in the sub-waveguide to the external vacuum environment as soon as possible, a row of circular ventilation holes is generally arranged on the central axis of the wide sides of the sub-waveguide, such as figure 1 as shown, figure 1 Among them, 1 is a sub-waveguide, 2 is a sub-waveguide partition, and 3 is a vent hole. The distance between adjacent vent holes and the size of the vent holes are determined by calculation, so that the flow resistance should be minimized so that the gas molecules can be discharged from the antenna unit as soon as possible, so as to maintain a high vacuum inside the antenna unit without affecting the high Normal transmission of power microwaves.

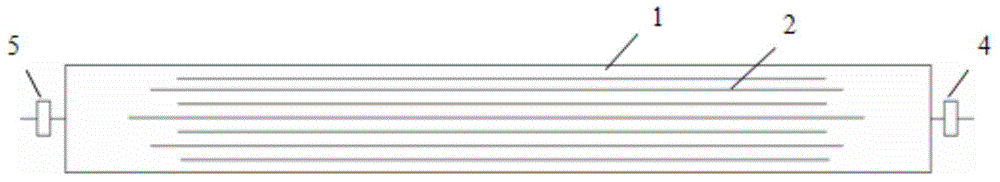

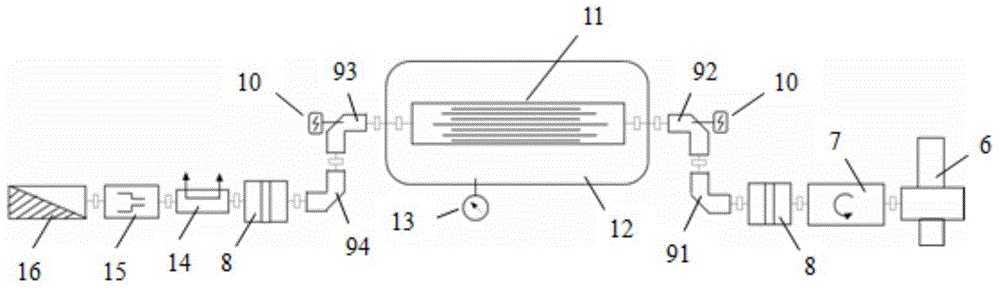

[0016] In addition, the output end of the antenna unit is an array composed of several sub-waveguides. In order to accurately measure the high power performance of the antenna unit in a vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com