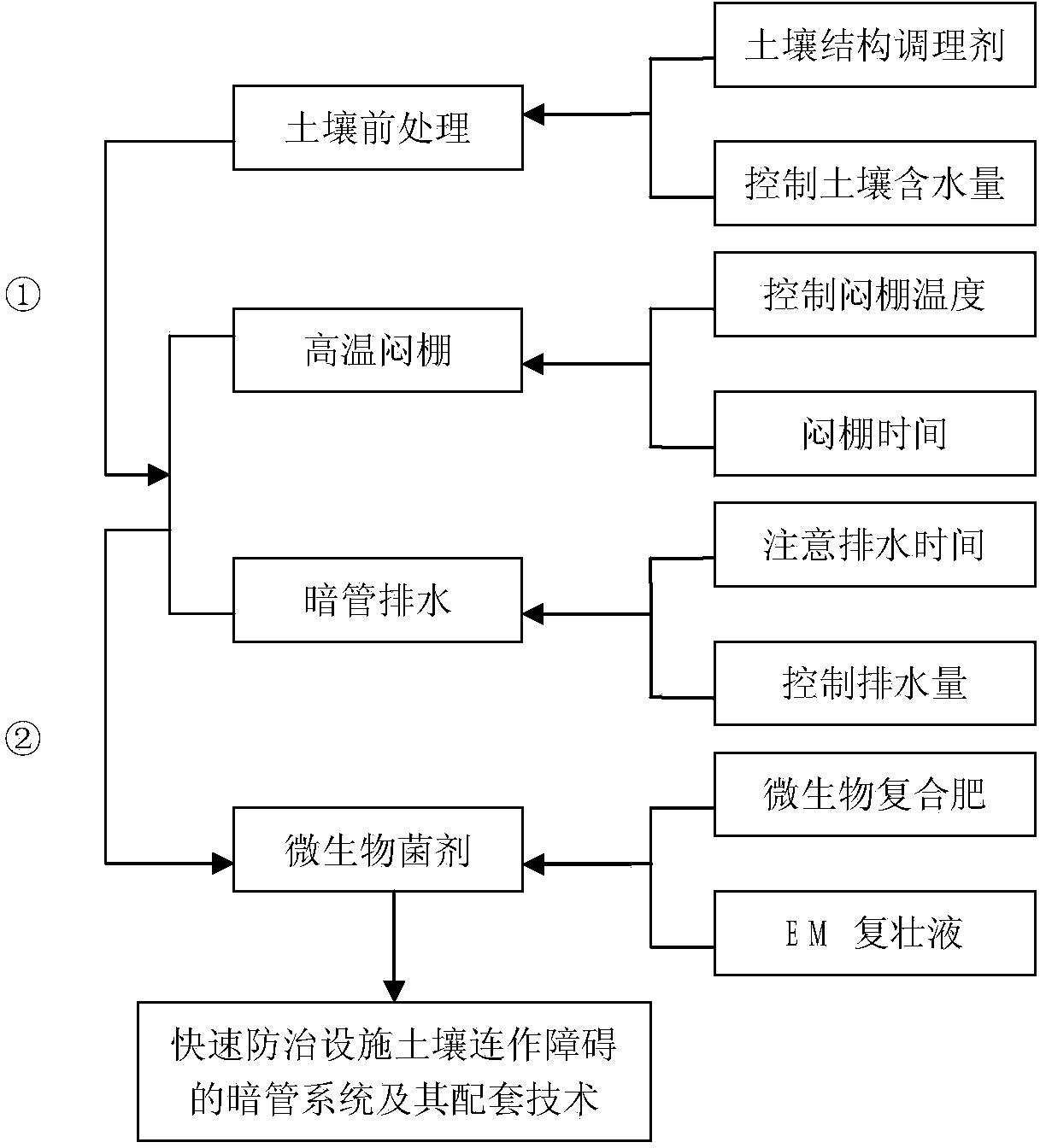

Method for rapidly preventing and treating successive cropping obstacles of greenhouse soil

A technology of soil continuous cropping obstacles and facilities, applied in the agricultural field, can solve the problems of insufficient drainage of underground pipes and lack of supporting technologies, and achieve the effect of reducing salinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for rapid prevention and treatment of facility soil continuous cropping obstacles comprises the following steps:

[0028] (1) Hidden pipe system: the material of the hidden pipe is made of plastic corrugated pipe, outsourced with non-woven fabric, the buried depth of the hidden pipe is 65cm, and the spacing is 6m;

[0029] (2) Soil pre-treatment: plow the facility soil to a depth of 15-30cm, and then apply 21.5kg / hm 2 Soil structure conditioner and fully irrigate until the soil water content reaches 67.5% of the field water capacity;

[0030] (3) High-temperature stuffy shed and underground pipe drainage: the time of stuffy shed needs to be during the summer crop change period, and the time of stuffy shed is 35 to 75 days; In the evening, to prevent irrigation from destroying the accumulation of soil temperature, the irrigation volume is 55mm / time;

[0031] (5) Microbial compound fertilizer: After the stuffy shed is over, ventilate and ventilate until the s...

Embodiment 2

[0040] The method for rapid prevention and treatment of facility soil continuous cropping obstacles comprises the following steps:

[0041] (1) Concealed pipe system: the material of the concealed pipe is made of plastic corrugated pipe, outsourced with non-woven fabric, the buried depth of the concealed pipe is 60cm, and the spacing is 5m;

[0042] (2) Soil pretreatment: plow the facility soil to a depth of 15-30cm, and then apply 20kg / hm 2 Soil structure conditioner and fully irrigate until the soil moisture reaches 65% of the field capacity;

[0043] (3) High-temperature stuffy shed and underground pipe drainage: the time of stuffy shed needs to be during the period of summer crop change, and the time of stuffy shed is 35 days; To prevent irrigation from destroying the accumulation of soil temperature, the irrigation volume is 50mm / time;

[0044] (5) Microbial compound fertilizer: After the stuffy shed is over, ventilate and ventilate until the soil temperature is lowered...

Embodiment 3

[0048] The method for rapid prevention and treatment of facility soil continuous cropping obstacles comprises the following steps:

[0049] (1) Concealed pipe system: the material of the concealed pipe is made of plastic corrugated pipe, outsourced with non-woven fabric, the buried depth of the concealed pipe is 70cm, and the spacing is 7m;

[0050] (2) Soil pretreatment: plow the facility soil to a depth of 15-30cm, and then apply 25kg / hm 2 Soil structure conditioner and fully irrigate until the soil moisture reaches 70% of the field capacity;

[0051] (3) High-temperature stuffy shed and underground pipe drainage: The time of stuffy shed needs to be during the summer crop change period, and the time of stuffy shed is 75 days; To prevent irrigation from destroying the accumulation of soil temperature, the irrigation volume is 60mm / time;

[0052] (5) Microbial compound fertilizer: After the stuffy shed is over, ventilate and ventilate until the soil temperature is lowered. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com