Fibula positioning and shaping assisting plastic device and manufacturing method thereof

A technology for assisting positioning and manufacturing methods, which is applied in computer-aided surgery, medical science, surgery, etc., can solve the problems of indeterminate surgical effect and inability to ensure installation accuracy, and reduce the difficulty and risk of surgery, with simple structure and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] With reference to the accompanying drawings, the manufacturing method of the fibula auxiliary positioning and shaping device includes the following steps:

[0015] 1. CT scanning is performed on patients with jaw defects, and then the CT is imported into the calculation to reconstruct the maxillofacial bone model and fibula model.

[0016] 2. On the reconstructed maxillofacial bone model, clarify the resection site and the cutting route of the diseased jaw, and simulate the cutting of the maxillofacial bone model in the computer along the cutting route; replace the resected diseased jaw model with the fibula model, find A substitute fibula segment model with the most suitable length and angle for the incision of the maxillofacial bone model was obtained.

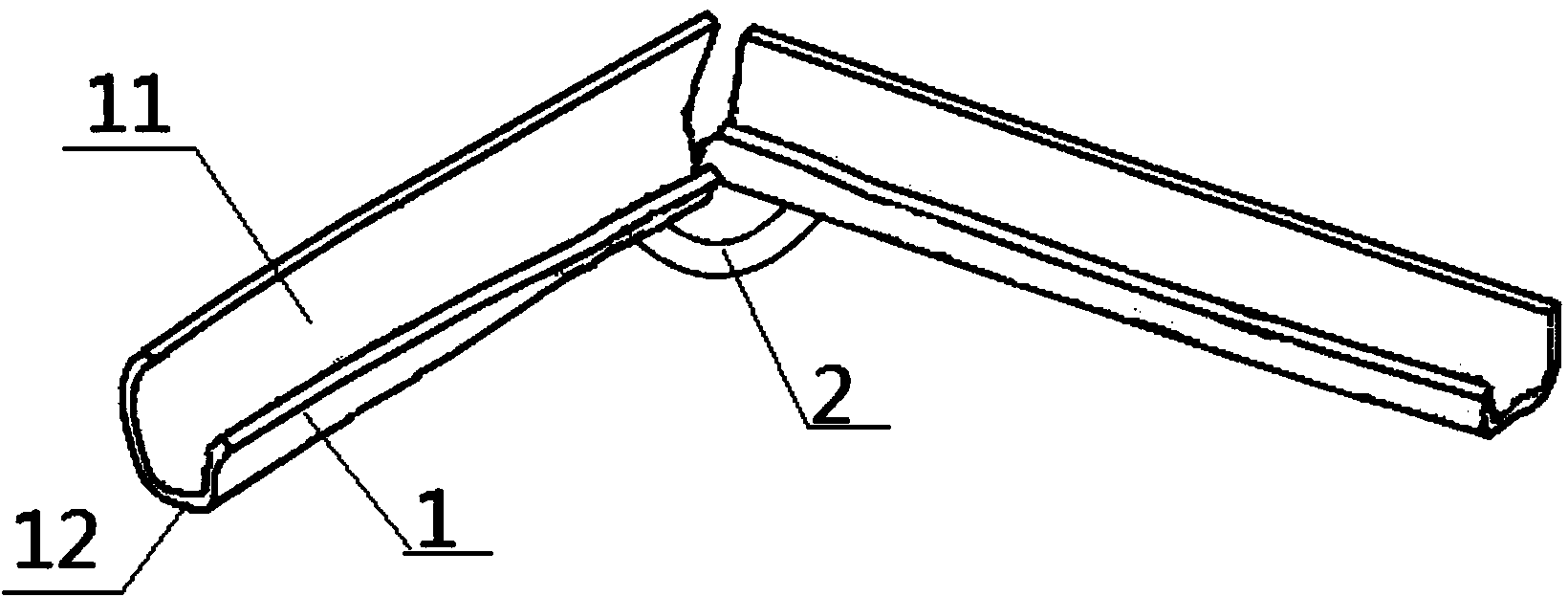

[0017] 3. Using the outer surface of the fibular segment model as the inner surface 11 of the positioning and shaping guide plate 1, perform three-dimensional modeling on the positioning and shaping guide plate 1 to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com