A Servo Direct Drive Harmonic Drive Spiral Bending Machine

A technology of harmonic drive and bending machine, which is applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of large sheet material limitations, low automation, and poor overall rigidity, and achieve high equipment reliability and structural integrity. The effect of compactness and large forming force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be explained in detail below with reference to the accompanying drawings.

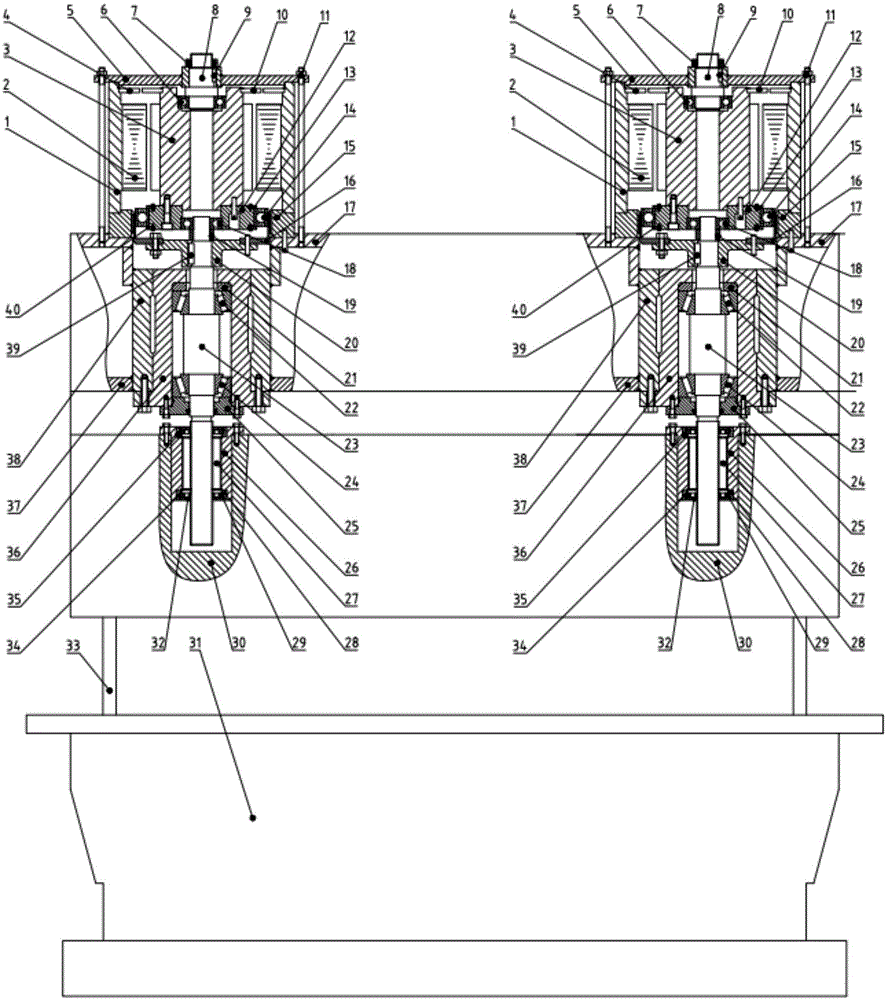

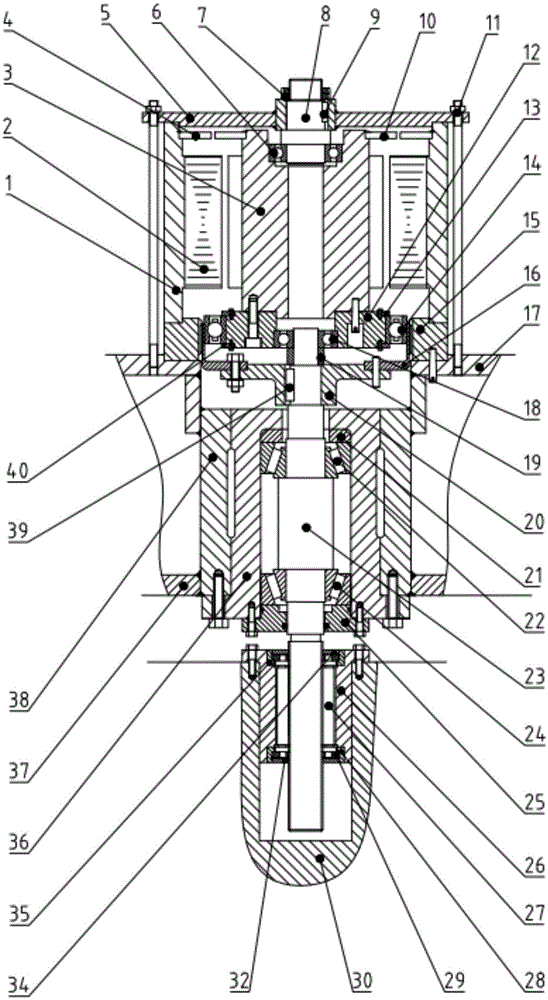

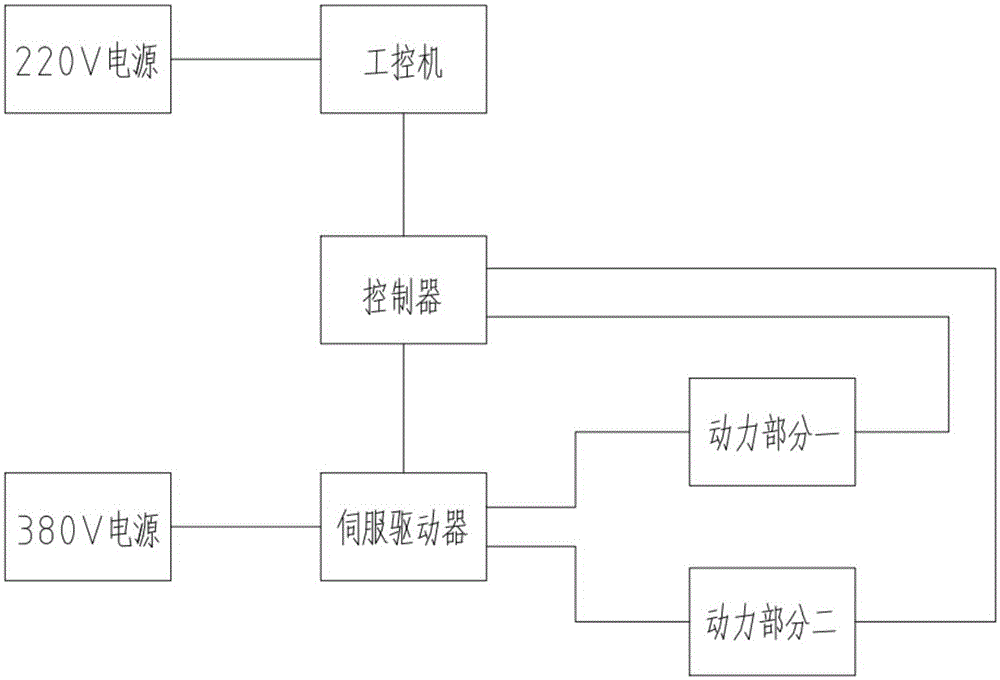

[0016] refer to figure 1 with figure 2 , a servo direct drive type harmonic transmission spiral bending machine, including two symmetrically arranged power parts, the main body of the power part is installed on the upper plate 17 of the top cavity and the lower plate 37 of the top cavity, and the output of the power part passes through the planetary roller The column screw mechanism is realized, and the planetary roller screw mechanism is connected to the slider 30 of the bending machine through screws, the slider 30 is connected to the fuselage 33, and the fuselage 33 is connected to the base 31;

[0017] refer to figure 2 , the power part includes a permanent magnet motor stator 2, and the permanent magnet motor stator 2 is fixed on the inner ring boss of the motor casing 1 by anaerobic glue or small screws; the tail of the permanent magnet motor rotor 3 is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com