Rubber roller bearing assembly machine

A technology for assembly machines and rubber rollers, applied in metal processing, metal processing equipment, hand-held tools, etc., can solve the problems of difficult installation accuracy, slow installation speed, and bearing damage, and achieve simple structure, damage resolution, and high precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

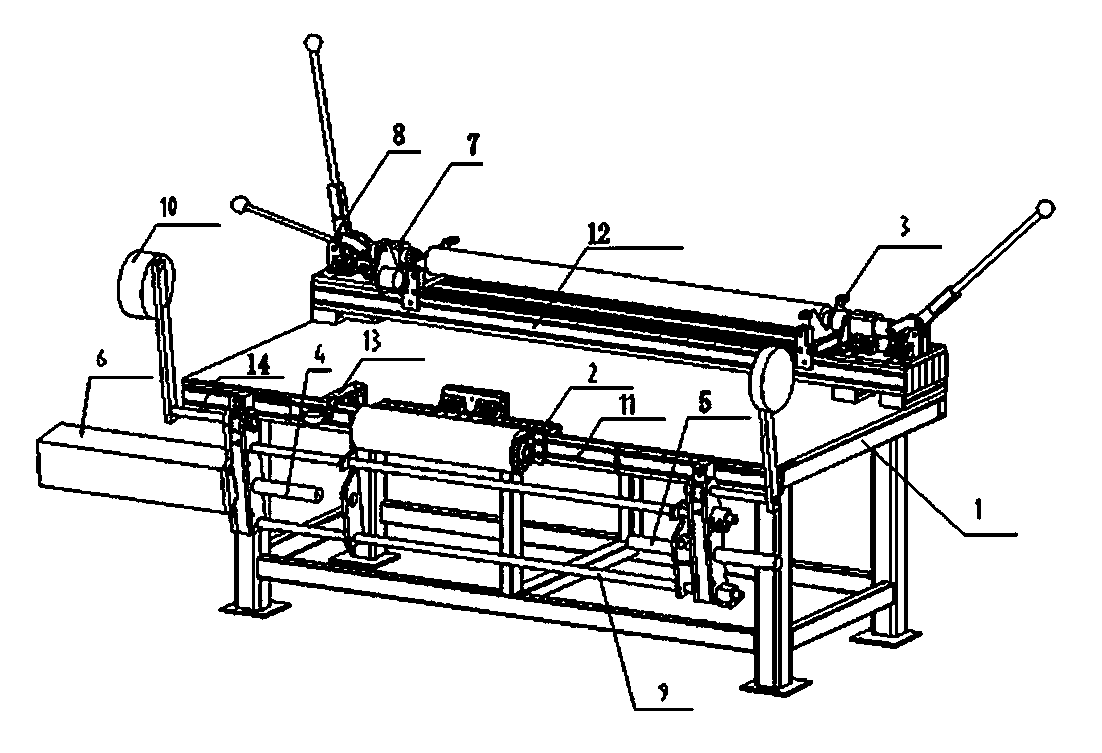

[0016] Embodiment: a rubber roller bearing assembly machine, comprising a workbench 1, a rotary chute 2, a workpiece support frame 3, the first and second push rods 4, 5, a driving device 6, a pressure head 7 and a quick pressing device 8, used The rotary chute 2 fixed to the rubber roller can be linearly slid and positioned on the workbench 1, the first and second ejector pins are coaxially positioned at both axial ends of the rotary chute 2, and the driving device 6 can drive the first ejector pin 4 toward the second The distance between the first and second ejector rods is reduced by sliding in the direction of the second ejector rod 5, and the first and second ejector rods can be coaxially corresponding to the rotary chute 2, the workpiece support frame 3 is fixed on the workbench 1, and the workpiece support frame 3 is provided with There is a fixing device for fixing the rubber roller. Two quick pressing devices 8 are symmetrically fixed and positioned at both axial ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com