Novel aluminum product polishing machine

A technology for polishing machines and aluminum materials, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, and parts of grinding machine tools, etc. problem, to achieve uniform polishing, eliminate longitudinal lines, and good polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

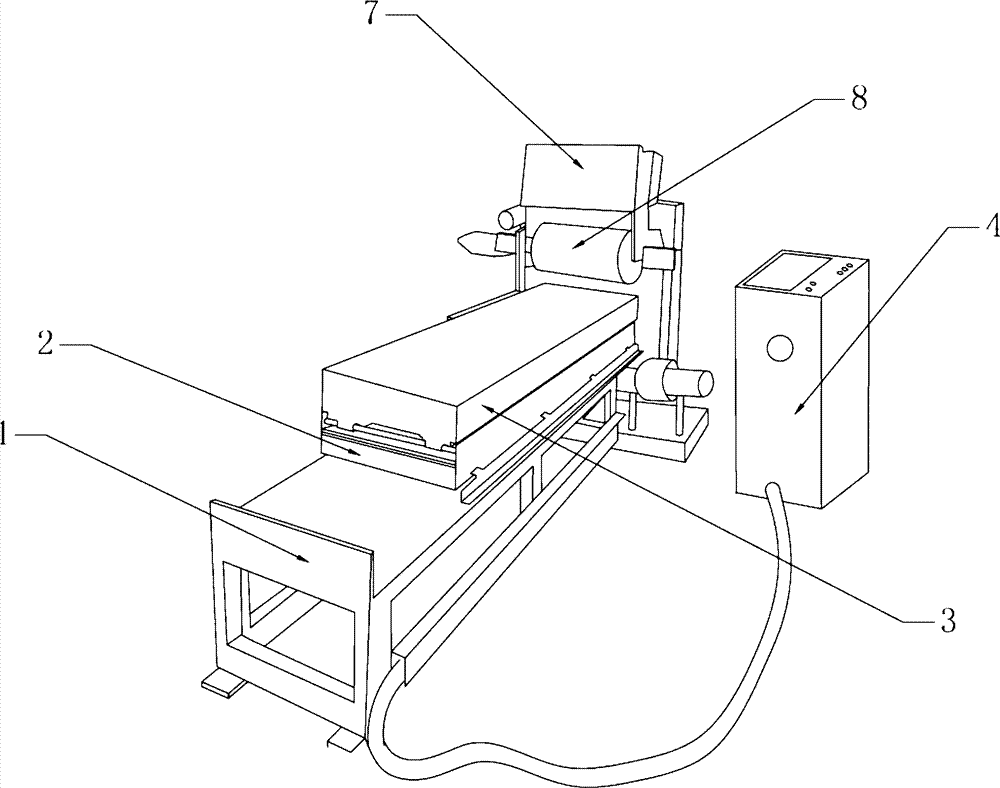

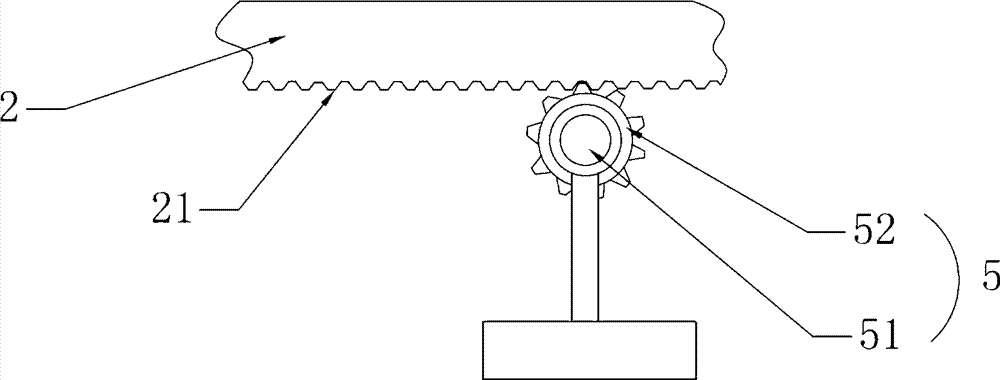

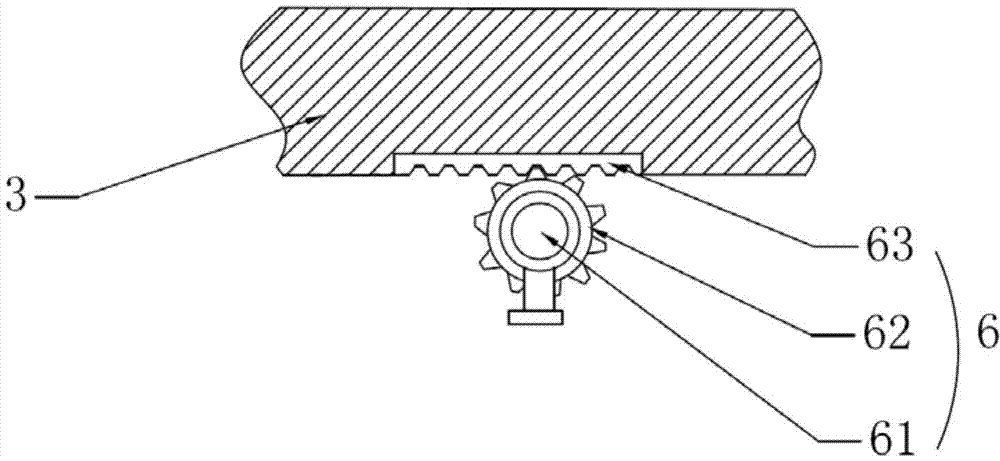

[0018] Please also see figure 1 , figure 2 and image 3 , The new aluminum polishing machine of the present invention includes a machine base 1, a workbench, a console 4, a longitudinal reciprocating mechanism 5, a transverse reciprocating mechanism 6, a polishing frame 7 and a polishing head 8. Described workbench comprises lower workbench 2 and upper workbench 3. The lower workbench 2 is vertically laid on the machine base 1 through the longitudinal reciprocating mechanism 5 , and the upper workbench 3 is arranged on the lower workbench 2 through the transverse reciprocating mechanism 6 . The console 4 is electrically connected to the longitudinal reciprocating mechanism 5 and the transverse reciprocating mechanism 6 respectively to control the working states of the longitudinal reciprocating mechanism 5 and the transverse reciprocating mechanism 6 . The longitudinal reciprocating mechanism 5 is used to reciprocate the lower table 2 in the longitudinal direction, and the...

Embodiment 2

[0024] The structure of this embodiment is similar to that of Embodiment 1, the difference is that: the transverse reciprocating mechanism includes a small motor and a ball screw; the small motor is arranged between the upper workbench and the lower workbench, and the ball screw The screw shaft of the rod is fixed on the output shaft of the small motor, and the screw nut axis of the ball screw is fixed on the bottom of the upper workbench along the transverse direction.

Embodiment 3

[0026] The structure of this embodiment is similar to that of Embodiment 1, the difference is that: the longitudinal reciprocating mechanism includes a motor and a ball screw; It is fixed on the output shaft of the motor, and the axis of the screw nut of the ball screw is fixed on the bottom surface of the lower worktable along the longitudinal direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com