Vibrating plate, liquid jetting device and printing device

A vibrating plate and nozzle technology, which is applied in printing and other directions, can solve the problems of film layer detachment, zirconia layer detachment, long annealing time, etc., and achieve the effect of not being easily warped and deformed, and preventing the reduction of displacement change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

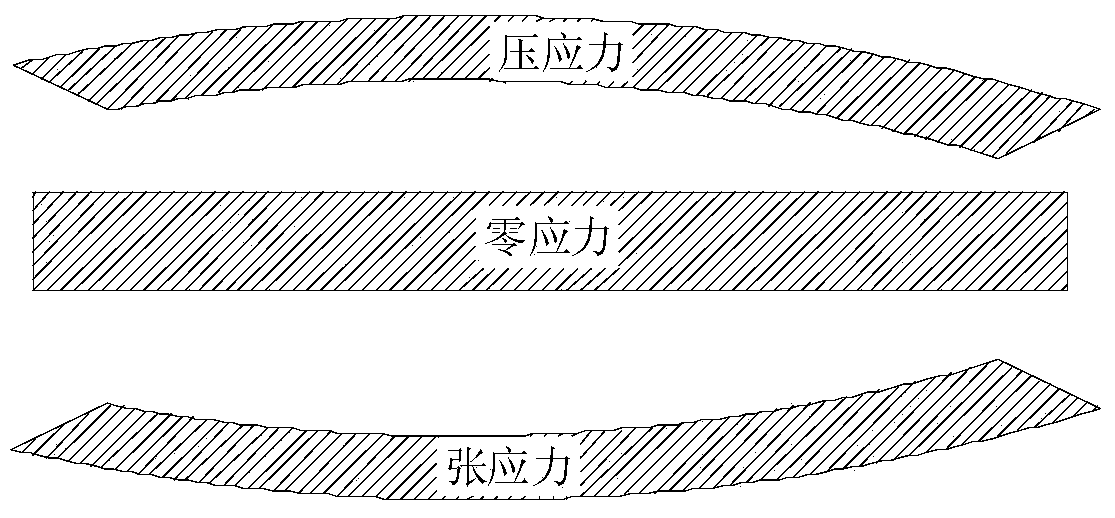

[0040] figure 1 It is a schematic diagram of the deformation of the vibrating plate when it is subjected to compressive stress or tensile stress or the stress is zero. Such as figure 1 As shown, when the internal stress of the vibrating plate is tensile stress, the vibrating plate will be subjected to the action of tensile stress, which will cause the two ends of the vibrating plate to be higher than the middle part of the warping deformation. When the internal stress of the vibrating plate is zero, the vibrating plate is in the In a naturally flat state, when the internal stress of the vibrating plate is compressive, the vibrating plate will be subjected to compressive stress, which will cause the middle part of the vibrating plate to be higher than the two ends of the warping deformation.

[0041] In the existing process of manufacturing nozzles, high-temperature oxidation or high-temperature calcination and annealing processes are required, and at the same time, due to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com