Semi-transmittance and semi-reflection type anti-dazzling electronic rearview mirror lens

An electronic anti-glare, transflective and transflective technology, applied in the field of rearview mirrors for vehicles, can solve the problems of insufficient transmittance, speeding up the time of electrochromic lens discoloration and imaging, and inability to clearly display reversing video and other issues. Fast response, improved transmittance and reflectivity, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

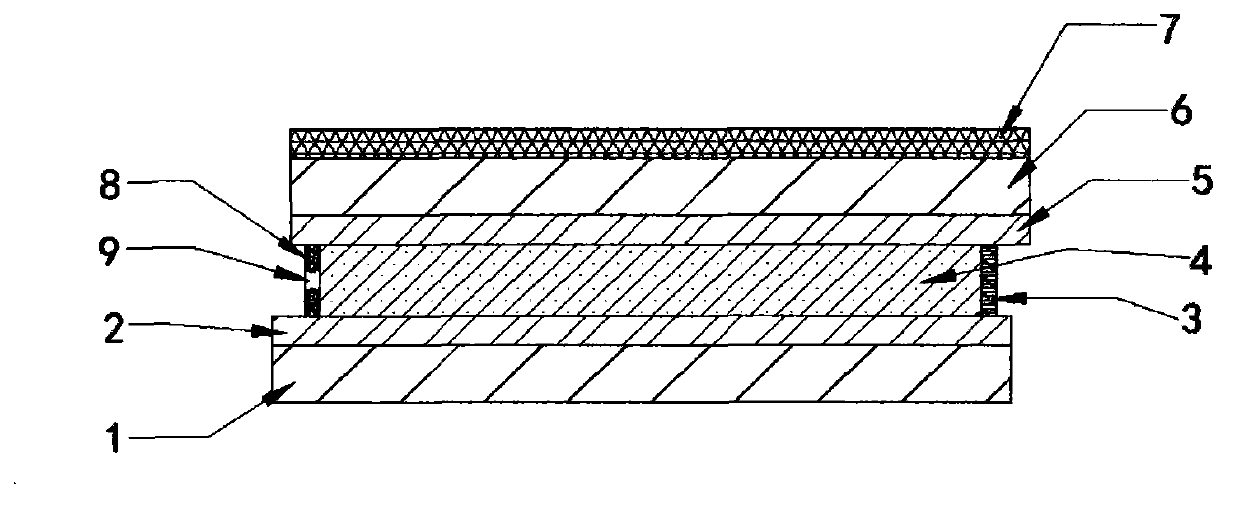

[0022] Such as figure 1 As shown, the transflective electronic anti-glare rearview mirror lens according to the embodiment of the present invention includes transparent glass one 1 and transparent glass two 6, transparent conductive layer one 2 and transparent conductive layer two 5, located on the transparent glass The inner surfaces of one 1 and transparent glass two 6 are plated with transparent conductive layer one 2 and transparent conductive layer two 5 by magnetron sputtering respectively, and the conductive layer one 2 and conductive layer two 5 are bonded together And the electrochromic material layer 4 is made and poured into the electrochromic material or electrochromic liquid crystal to form the overall structure of the lens and the outer frame of the electrochromic material layer 4 of the lens is sealed by epoxy resin glue 3; One side of the outer frame of the electrochromic material layer 4 is provided with a filling port 9 for pouring in the electrochromic mater...

Embodiment 2

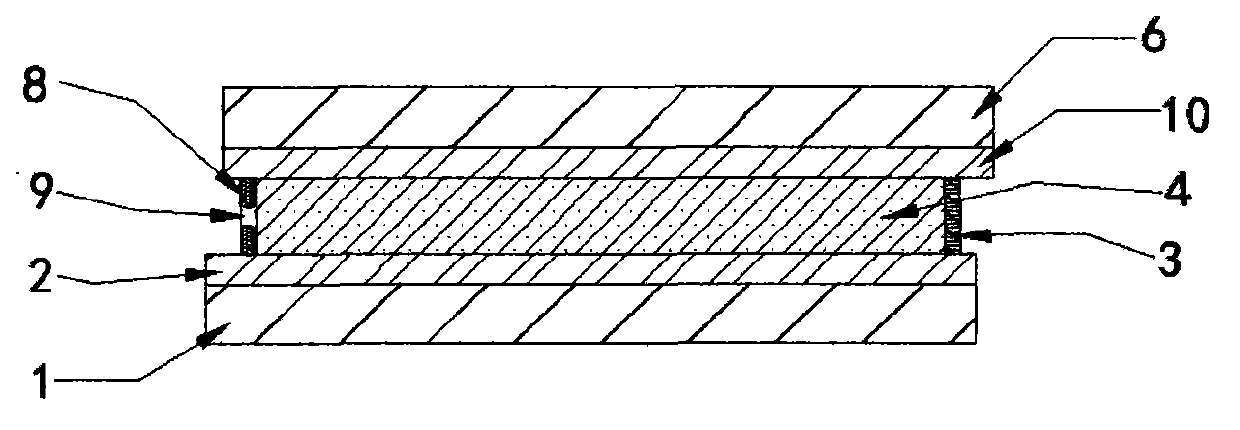

[0025] Such as figure 2 As shown, the transflective electronic anti-glare rearview mirror lens according to the embodiment of the present invention includes transparent glass one 1 and transparent glass two 6, the glass thickness of which is 1.1-2.0mm, transparent conductive layer one 2 and transparent glass two 6. The silver or silver alloy coating layer 10 is positioned at the respective inner surfaces of the transparent glass 1 and the transparent glass 2 6 and is respectively plated with a transparent conductive layer 1 2 and a silver or silver alloy coating layer 10 by magnetron sputtering. Layer one 2 and silver or silver alloy coating layer 10 are laminated to form electrochromic material layer 4 and filled with electrochromic material or electrochromic liquid crystal to form the overall structure of the lens and the lens The outer frame of the electrochromic material layer 4 is sealed by epoxy resin glue 3; at the same time, one side of the outer frame of the electroc...

Embodiment 3

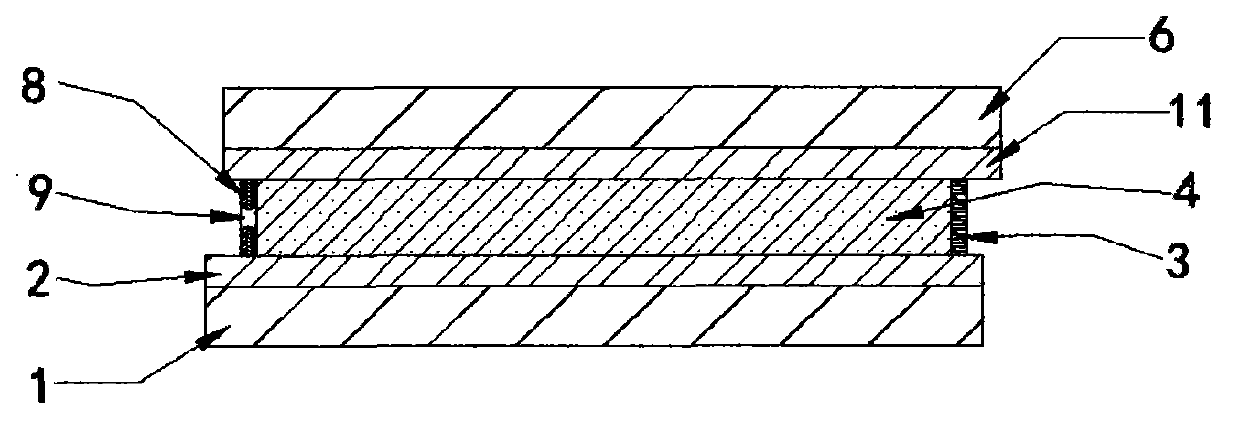

[0028] Such as image 3 As shown, the transflective electronic anti-glare rearview mirror eyeglass lens described in the embodiment of the present invention comprises transparent glass one 1 and transparent glass two 6, transparent conductive layer one 2 and dielectric film plus ITO film 11, is positioned at transparent The respective inner surfaces of glass one 1 and transparent glass two 6 are respectively plated with a transparent conductive layer one 2 by magnetron sputtering, and a dielectric film is filled with an ITO coating 11, and the transparent conductive layer one 2 and the dielectric film are added with an ITO coating 11 The two are bonded to form an electrochromic material layer 4 and filled with electrochromic material or electrochromic liquid crystal to form the overall structure of the lens and the outer frame of the electrochromic material layer 4 of the lens is made of epoxy resin glue 3 sealing; at the same time, one side of the outer frame of the electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com