High-purity bivalirudin and industrial preparation method thereof

A technology of bivalirudin and its synthesis method, which is applied in the field of high-purity pharmaceutical peptides and its industrial preparation, can solve the problems of environmental pollution, high cost of recycling, not a washing solvent, etc., so as to reduce production costs and waste liquid discharge , the effect of low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

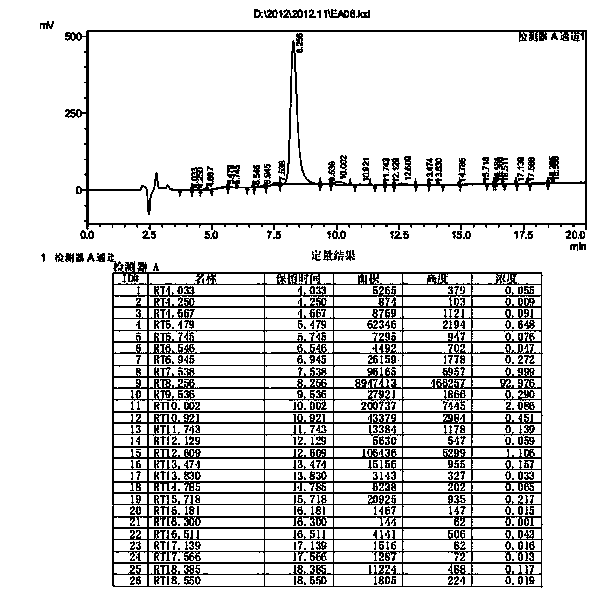

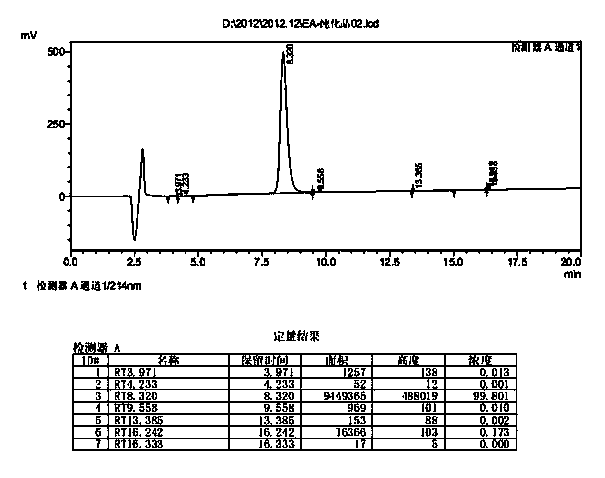

Image

Examples

Embodiment 1

[0042] Adopt technical scheme described in the present invention to prepare bivalirudin

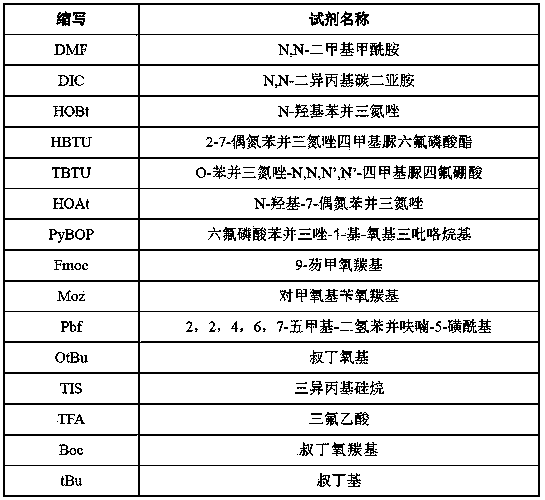

[0043] 1. Weigh 1 kg of Leu-Wang Resin (SD=0.60 mmol / g) resin into a silanized glass reactor, add 6 L of DMF to completely immerse the resin in it, stir for 30 min, and filter the DMF with suction. Dissolve Fmoc-Tyr-OH (0.55 kg, 1.2 mol) and HOBt (0.173 kg, 1.3 mol) in 3.3 L DMF at room temperature, add to the above resin and stir well, then add DIC (0.2 L, 1.3 mol) , stirred for 3~4 h. After detection by Kaiser reagent, the resin was colorless and the reaction solution was taken away.

[0044] 2. Add 4 L of ethyl acetate and stir for 5 minutes, then remove the washing solution.

[0045] 3. Add 5 L of 20% piperidine DMF solution by volume to the resin, stir and react for 3-10 min, and filter off the reaction solution with suction.

[0046] 4. Add 4 L of ethyl acetate and stir for 5 minutes, remove the washing solution, and repeat washing once.

[0047] 5. Add 5 L of 20% piperidine DMF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com