Halogen-free resin composition, and prepreg and laminated board prepared from same

A resin composition and prepreg technology, which is applied in the fields of electronic materials, integrated circuit packaging, high-frequency, high-speed and high-density interconnection, can solve the problems of increasing moisture absorption rate and decreasing electrical properties, and achieve improved moisture and heat resistance, resistance Good hygroscopicity and low dielectric constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

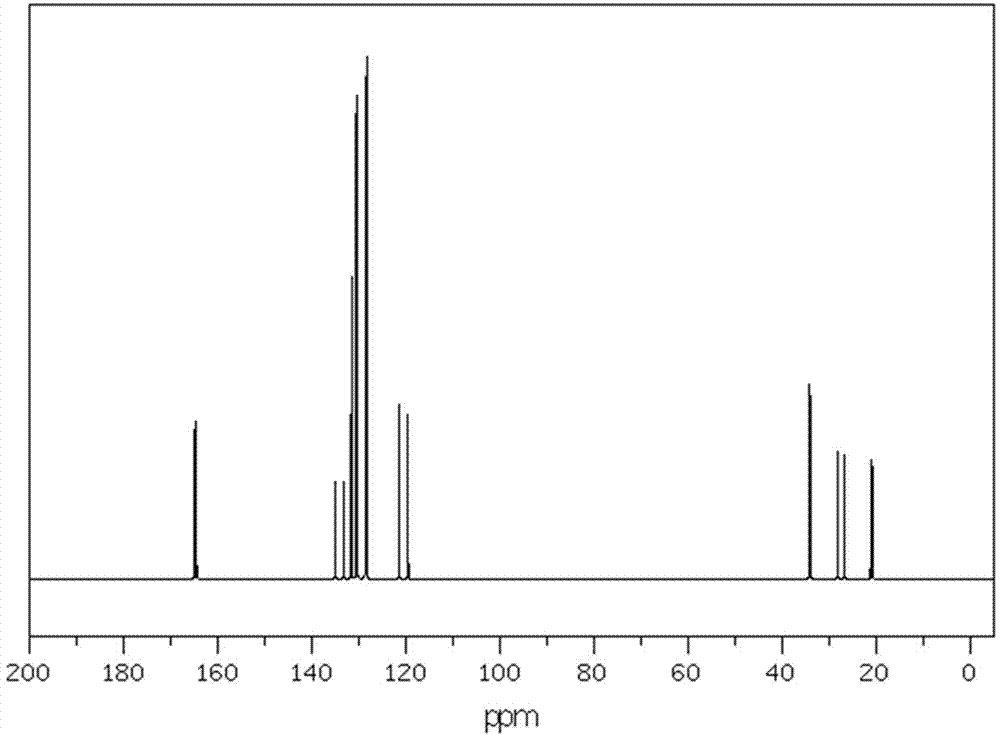

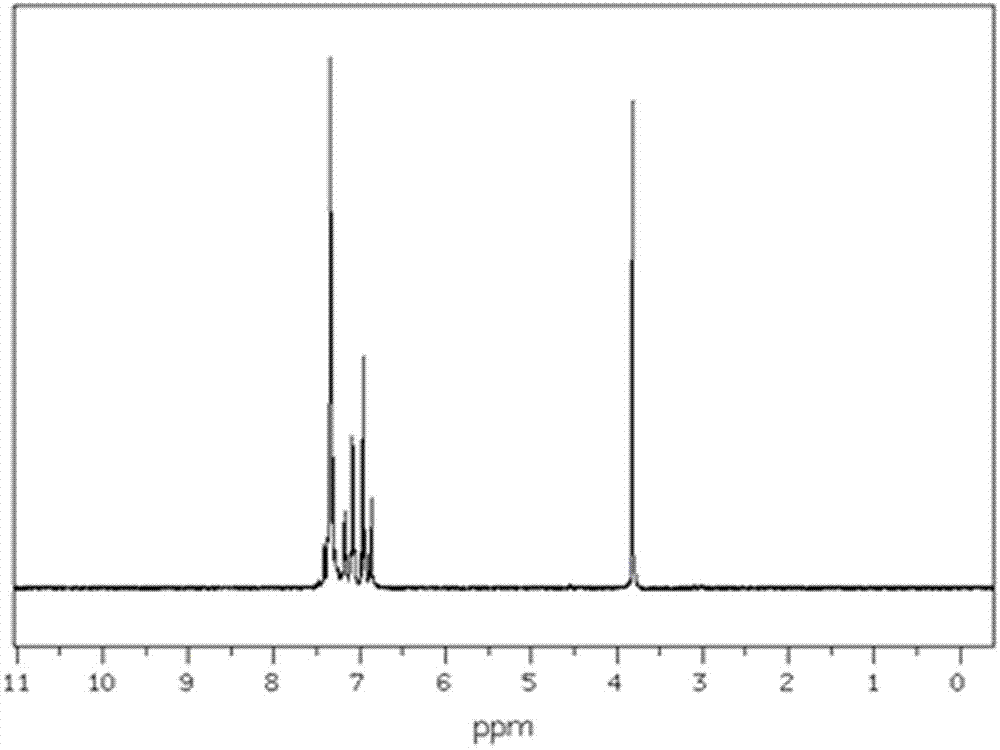

[0044] Synthesis Example 1: Preparation of phosphorus-containing active ester compound

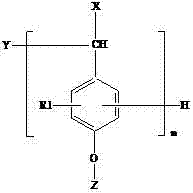

[0045] Weigh 0.6mol of 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide and 0.6mol of p-hydroxybenzaldehyde, add 65% mass Concentration of H 2 SO 4 , condensed and refluxed at 100°C for 3 to 5 hours, and then the mixture was washed with alcohol 4 to 6 times to obtain the pre-product; the above-mentioned pre-product was dissolved in toluene solution, and 0.2mol of benzoic acid was added. temperature conditions, add 0.05mol catalyst (AlCl 3 ), condensed and refluxed for 4 hours, and then after several times of washing, dried for 4 hours under vacuum at 105°C to obtain the desired phosphorus-containing active ester compound with an esterification rate of 70-80% and a phosphorus content of 6.4%. Phosphorus-containing active ester compound, denoted as C1, the specific structure is as follows:

[0046]

[0047] X= , Y=H, Z= , R is phenyl, R1=CH 3 , n is 3-5....

Embodiment

[0054] According to the weight ratio shown in Table 1, benzoxazine resin, epoxy resin, phosphorus-containing active ester compound, curing agent, curing accelerator, inorganic filler and solvent are added to the mixing tank, and the solid content of the glue is controlled to be 65%. , stirred evenly, and aged for 8 hours to make a resin composition glue; then impregnated the glass cloth in the above resin composition glue; then baked the impregnated glass cloth at 160°C for 5 minutes to form a prepreg; After the prepreg is cut to a certain size, 8 prepregs are superimposed to form a stack, and an electrolytic copper foil is placed on the top and bottom of the stack, and sent to a vacuum press for pressing. The program is 150°C / 60min+200°C / 120min, a laminated board was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap