Liquid steel slag solidification dispersion treatment system

A liquid steel slag and dispersion treatment technology, applied in the field of steel slag processing, can solve the problems of difficult to meet the actual needs of industrial production, complex equipment structure, and low service life, and achieve the effect of simple structure, simple operation process and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

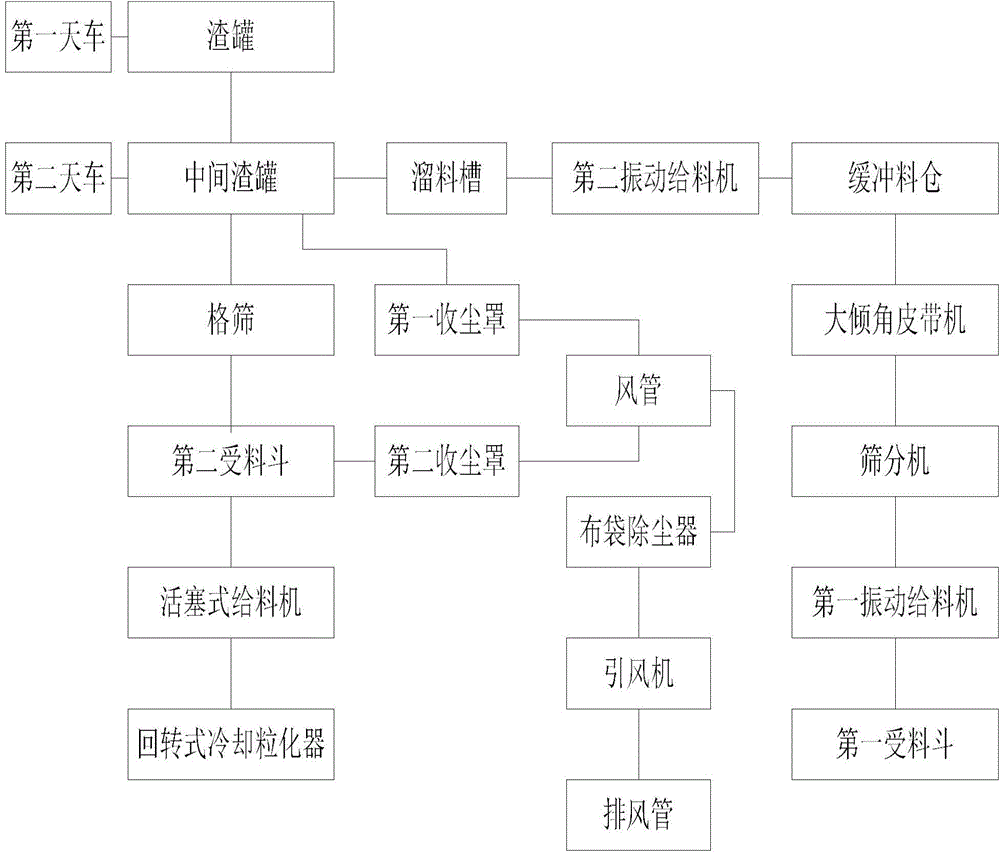

[0013] see figure 1 , The embodiment of the present invention provides a liquid steel slag solidification and dispersion treatment system, including: a cooling dispersant delivery unit, a liquid steel slag delivery unit, an intermediate slag tank, a solidified steel slag delivery unit, a dust removal unit and a rotary cooling granulator. The outlet of the cooling and dispersing agent delivery unit is arranged above the intermediate slag tank, and the cooling and dispersing agent delivery unit delivers the cooling and dispersing agent to the intermediate slag tank. The outlet of the liquid steel slag conveying unit is arranged above the intermediate slag tank, and the slag tank transports the liquid steel slag stored inside to the intermediate slag tank. The outlet of the intermediate slag tank is set above the solidified steel slag conveying unit, and the solidified steel slag conveying unit is connected with the rotary cooling granulator, and the solidified steel slag formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com