A kind of preparation method of graphene fiber

A technology of graphene fiber and graphite, which is applied to the chemical characteristics of fibers, textiles and papermaking, chemical post-treatment of rayon, etc. It can solve the problems of complex process and high temperature, and achieve the effect of simple operation, low cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Prepare graphene oxide solution by using improved oxidation exfoliated graphite method:

[0035] Add 10g of graphite, 150ml of 98% sulfuric acid, and 30ml of nitric acid into a 500ml Erlenmeyer flask and stir at room temperature for 24 hours, slowly pour it into 1L of water to collect the solid, wash 3 times, and dry at 80°C for 4 hours. Repeat the pre-oxidation process twice. The dried pre-oxidized graphite was put into a box furnace and thermally expanded at 900°C for 20s to obtain thermally expanded graphite oxide. In a 500ml wide-mouth Erlenmeyer flask, mix 5g of heat-expandable graphite oxide with 300ml of sulfuric acid, 5gK 2 S 2 o 8 , 7g of phosphorus pentoxide mixed and heated at 80°C for 4 hours, diluted with 2L of water, filtered and washed, dried in air for 3 days to obtain pre-oxidized thermally expandable graphite. Mix dry pre-oxidized heat-expandable graphite with 200ml of sulfuric acid at a low temperature of 0-5°C, add 20g of potassium permangana...

Embodiment 2

[0042] Repeat Example 1, except for the following differences, other conditions are the same: the 2mg / ml graphene oxide mixed solution prepared by mixing the pure graphene oxide solution with the water-soluble reducing agent hydroiodic acid (HI) is loaded into In a PP plastic tube with a diameter of 8 mm, seal it, and the mass ratio of graphene oxide to water-soluble reducing agent is 1:200.

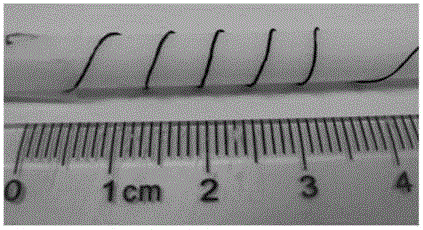

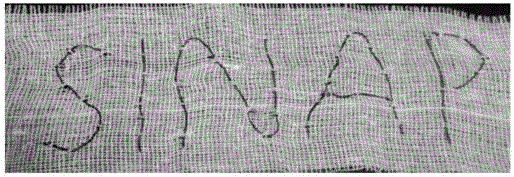

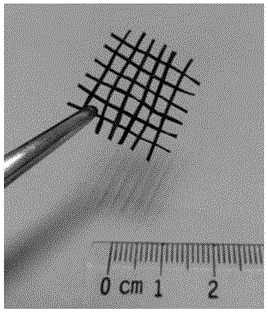

[0043] The photo of the obtained graphene fiber is similar to Example 1, and its fiber diameter and tensile strength are shown in Table 1.

Embodiment 3

[0045] Repeat Example 1, except for the following differences, other conditions are the same: pure graphene oxide solution and water-soluble reducing agent NaHSO 3 Mix the prepared 8mg / ml graphene oxide mixed solution and put it into a PP plastic tube with a diameter of 2.5mm, wherein the mass ratio of graphene oxide to water-soluble reducing agent is 1:300; put the sealed plastic tube at 70°C Conditions of heating for 3h.

[0046] The photo result of the obtained graphene fiber is similar to Example 1, and its fiber diameter and tensile strength are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com