Integrated screw type medium-pressure air compressor

An air compressor, screw compression technology, applied in mechanical equipment, pump combination for elastic fluid rotary piston type/oscillating piston type, machine/engine, etc., can solve the problems that have not been widely promoted and developed, and achieve convenience Controlling, reducing land occupation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

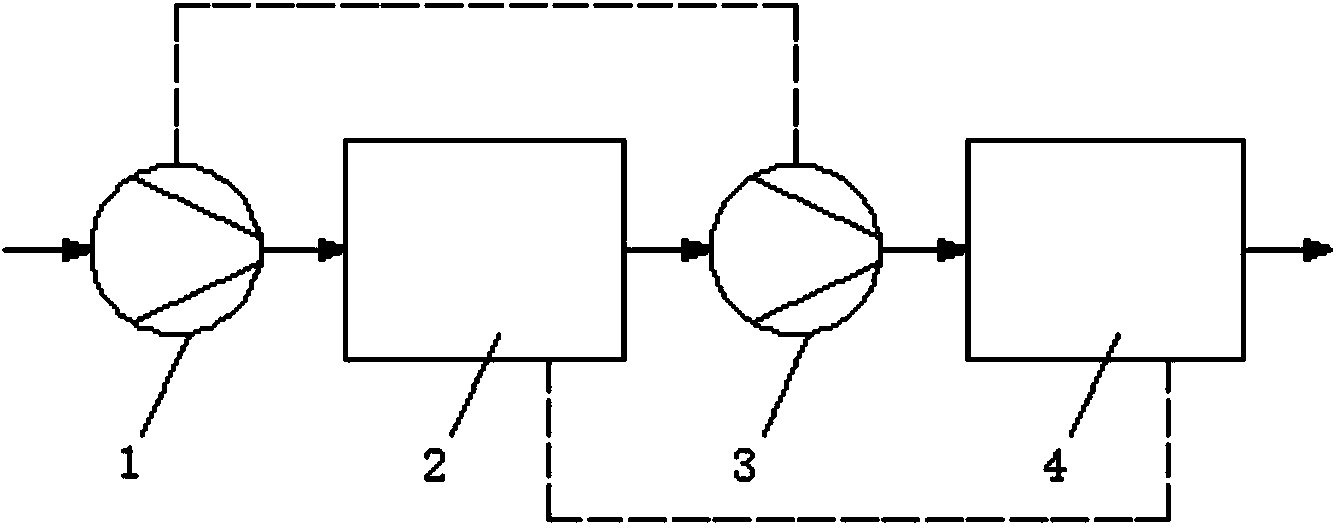

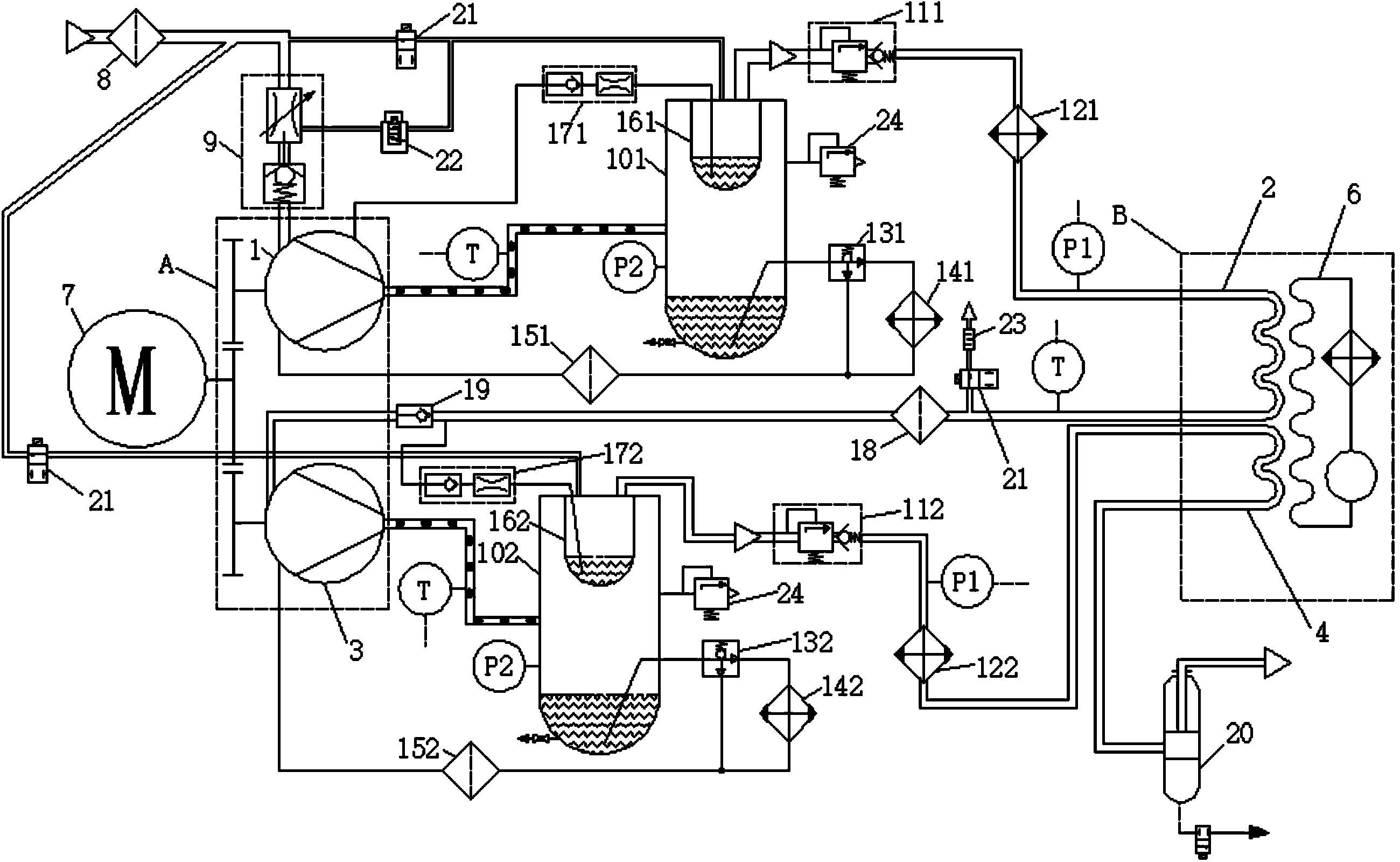

[0063] Embodiment: a kind of integrated screw medium pressure air compressor, such as figure 1 As shown, it includes a first-stage screw compressor host 1, a first-stage freeze dryer 2, a second-stage screw compressor host 3 and a second-stage freeze dryer 4 connected in series;

[0064] Wherein, the first-stage screw compression host 1 and the second-stage screw compression host 3 are integrated through a common gearbox 5 to form a two-stage compression screw host A;

[0065] Wherein, the first-stage freeze dryer 2 and the second-stage freeze dryer 4 are integrated through a common cooler 6 to form a two-stage freeze dryer B.

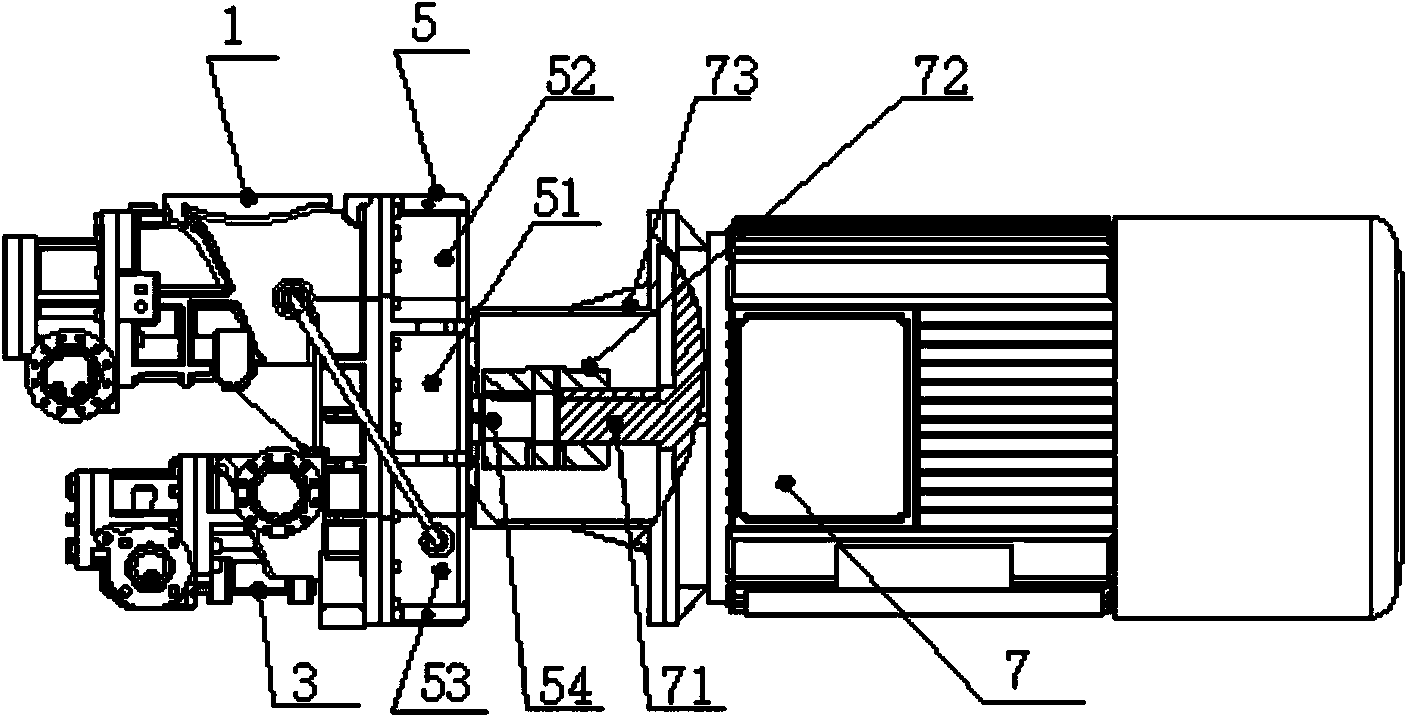

[0066] Such as figure 2 As shown, the structure in which the first-stage screw compressor host 1 and the second-stage screw compressor host 3 are integrated through a common gear box 5 is: the gear box is provided with a driving gear 51 and a first-stage driven gear 52 and a secondary driven gear 53, the primary driven gear 52 and the secondary driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com