Air drive hydraulic power system used on corner combination machine

A gas-driven hydraulic and power system technology, applied in the direction of mechanical equipment, servo motor components, fluid pressure actuators, etc., can solve the problems of low working efficiency, power performance decline, oil heating and temperature rise of hydraulic drive systems, etc., to achieve saving Energy, stable output pressure, and energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

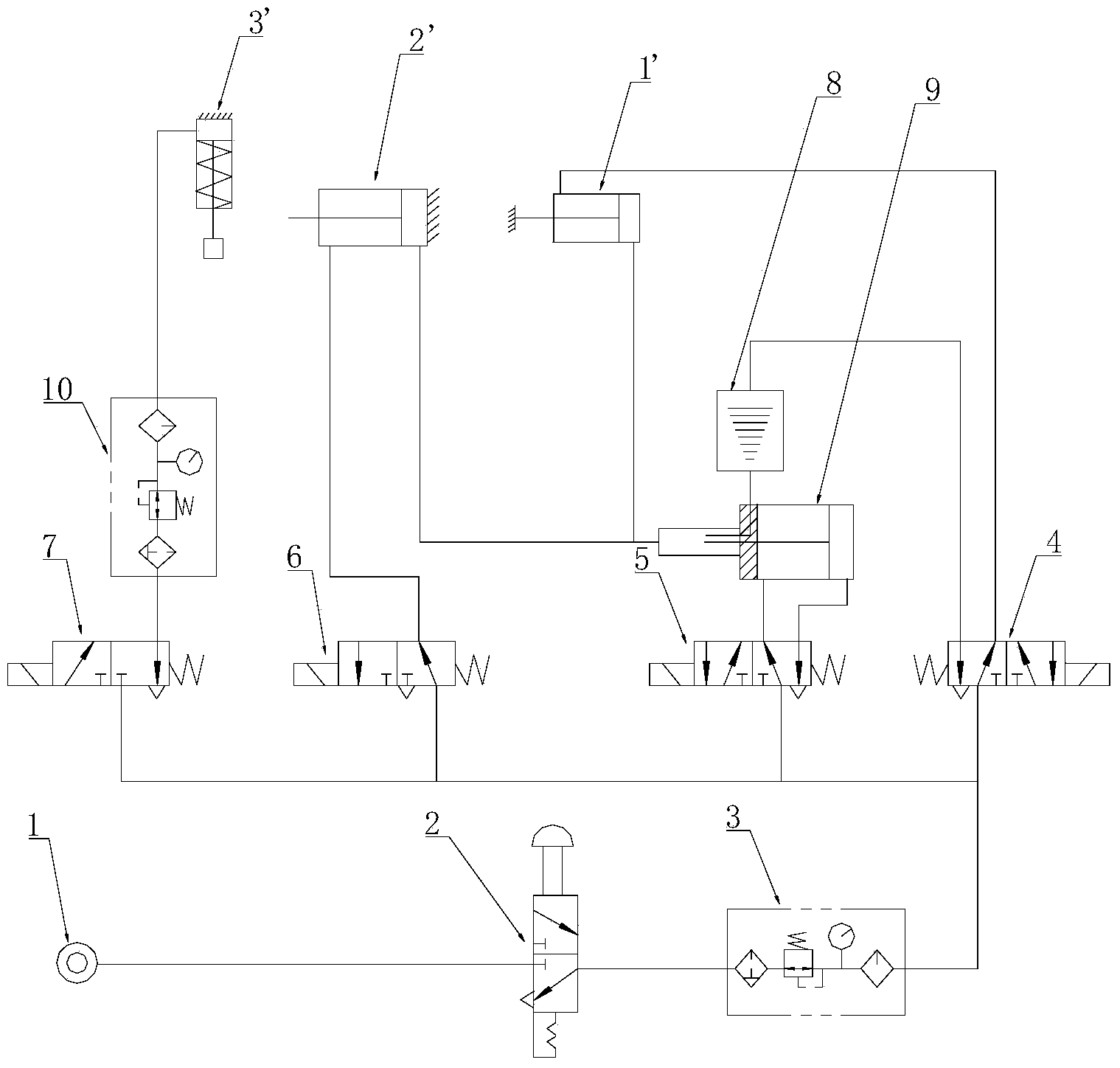

[0023] see figure 1 , an air-driven hydraulic power system on a corner machine, including air source 1, air source switch valve 2, air source processor A3, two-position five-way solenoid valve A4, two-position five-way solenoid valve B5, two-position three-way solenoid valve Through solenoid valve A6, two-position three-way solenoid valve B7, gas-liquid converter 8 and gas-liquid booster cylinder 9. The function of the air source processor A is to filter and adjust the pressure of the compressed air output from the air source before entering each solenoid valve. The air inlet and outlet of the air source switch valve are respectively connected to the air source and the air inlet of the air source processor A. The air inlet, positive action ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com