Bipolar-electrode electrochemiluminescence imaging electrolytic cell

A bipolar electrode, luminescence imaging technology, applied in chemiluminescence/bioluminescence, electrochemical variables of materials, analysis by chemical reaction of materials, etc. The problem of low reuse rate of pool channels, etc., achieves the effect of extending the scope of application, simple structure and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

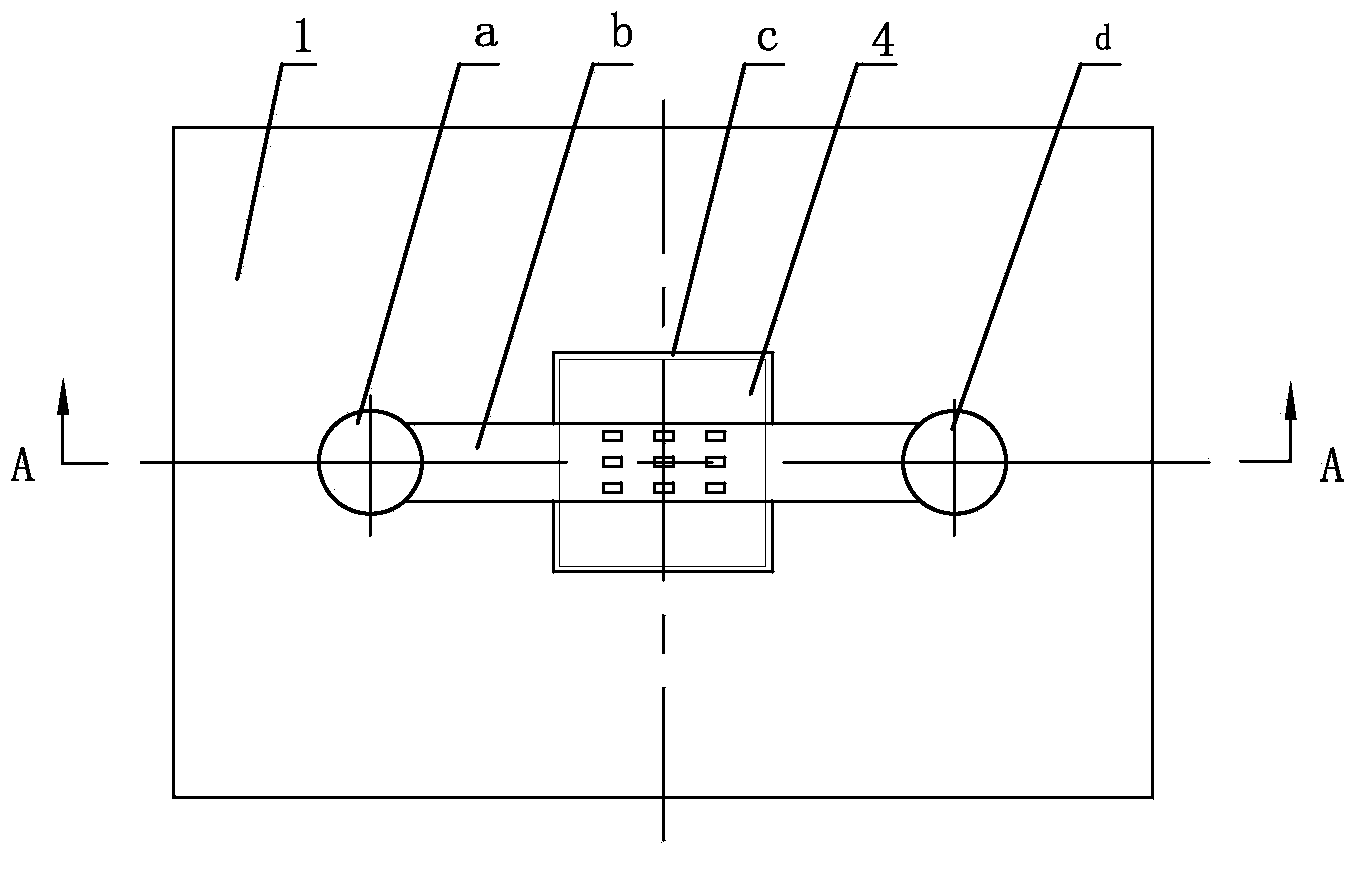

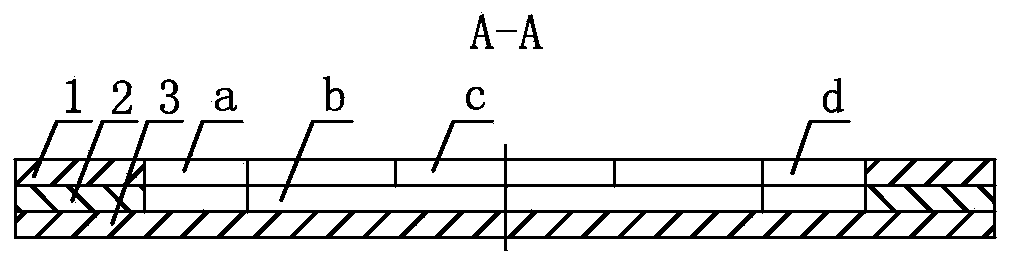

[0014] Such as figure 1 , 2 As shown, the bipolar electrode electrochemiluminescence imaging electrolytic cell of this embodiment is composed of an upper substrate 1 , a middle substrate 2 , and a lower substrate 3 .

[0015] The upper surface of the lower substrate 3 is bonded with the middle substrate 2, the upper surface of the middle substrate 2 is bonded with the upper substrate 1, the upper substrate 1, the middle substrate 2, and the lower substrate 3 are organic glass sheet. An electrolytic cell c is processed at the center of the upper substrate 1, the structure of the electrolytic cell c is a square groove, the bottom of the square groove is the middle substrate 2, and the side length of the square groove is 8.5 mm. And the central position of substrate 2 is processed with channel b, the shape of channel b is a rectangular groove, the bottom of the rectangular groove is the lower substrate 3, the length of the rectangular groove is 20mm, and the width is 3mm. For ...

Embodiment 2

[0017] The structure of the electrolytic cell c is a square groove, the side length of which is 6mm, the shape of the channel b is a rectangular groove, the length of the rectangular groove is 16mm, and the width is 2mm, and the shape of the left storage tank a is circular The groove, the diameter of the circular groove is 4mm, the structure of the right reservoir d is exactly the same as that of the left reservoir a. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0019] The structure of the electrolytic cell c is a square groove, the side length of which is 9mm, the shape of the channel b is a rectangular groove, the length of the rectangular groove is 22mm, and the width is 3mm, and the shape of the left storage tank a is circular Groove, the diameter of the circular groove is 5mm, and the structure of the right reservoir d is exactly the same as that of the left reservoir a. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Side length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com