Method For Determining Arc Discharge As Well As Failure Of Mechanical Vibration And Abnormal Displacement In Power Equipment Using Acoustic Energy Feature

A technology of electric power equipment and arc discharge, which is applied in the direction of measuring vibration, testing dielectric strength, and vibration measurement in solids, etc. It can solve the problems of inability to eliminate accidents, uncertainties, and inability to detect internal defects of equipment, etc., and achieve online detection of electric power Effect of device security posture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure and effect of the present invention will be described in detail by citing the following embodiments in conjunction with the accompanying drawings.

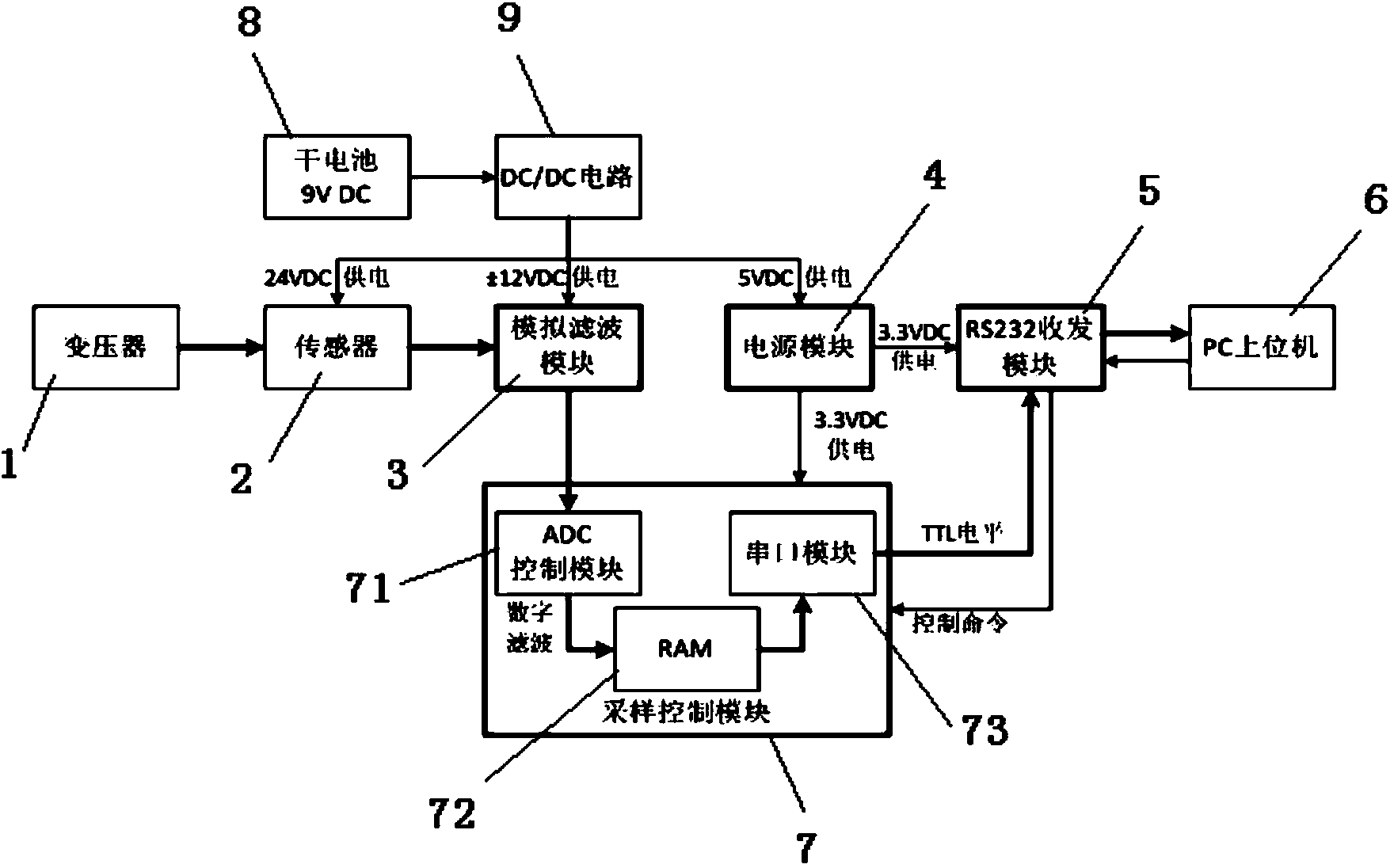

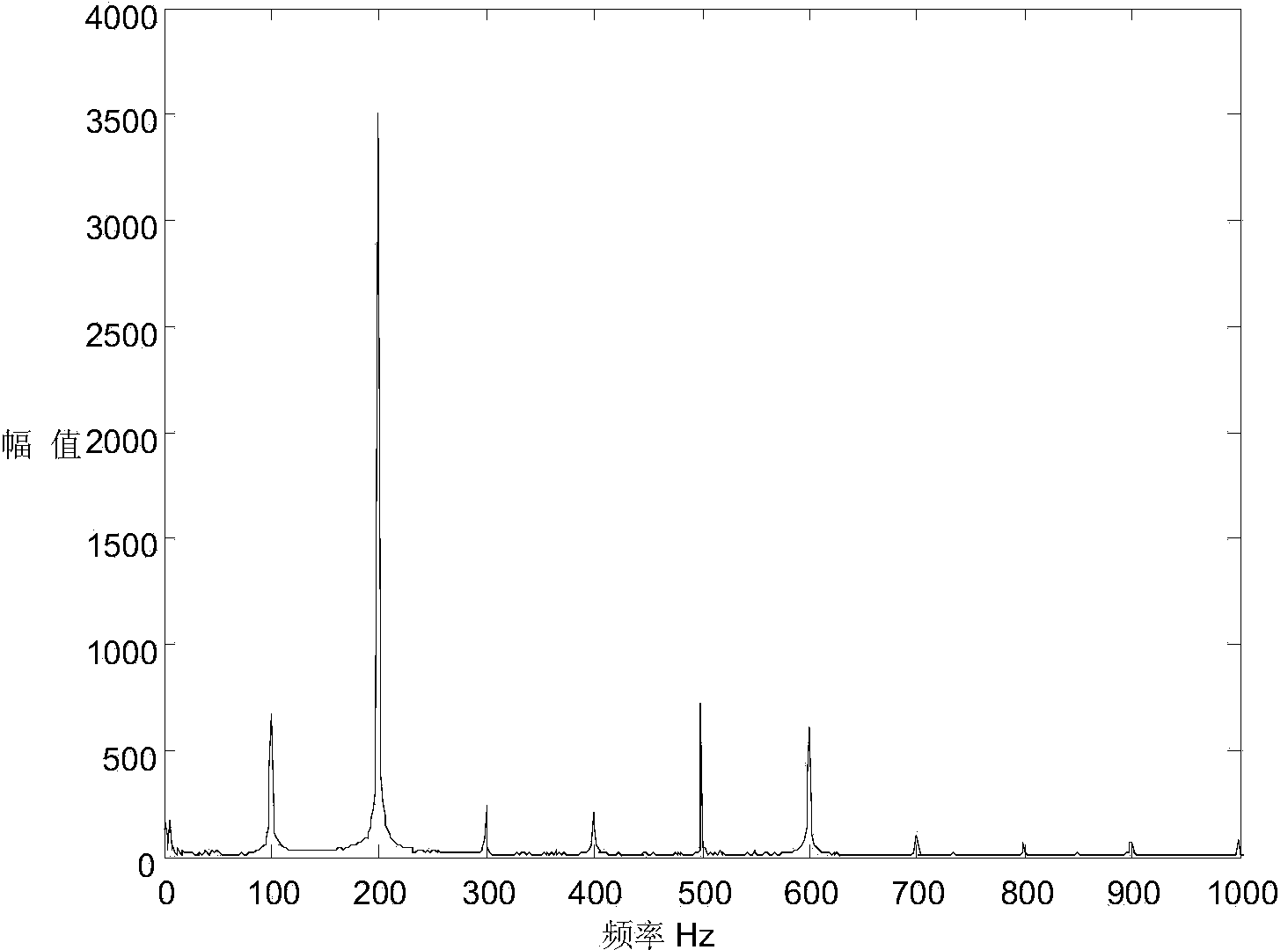

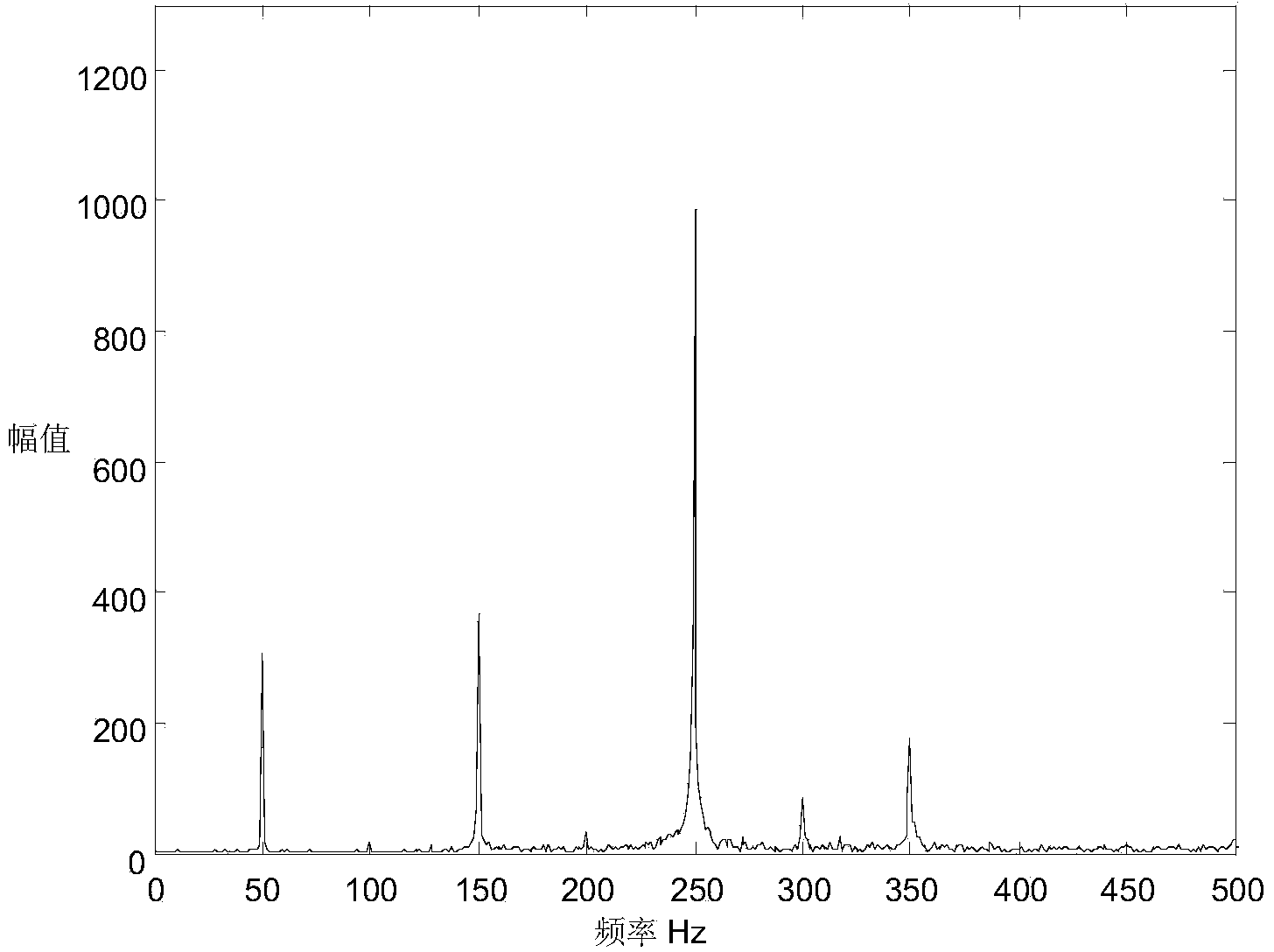

[0018] One of the principles based on the method for judging arc discharge, mechanical vibration, and abnormal displacement faults of electric equipment designed by the present invention is to use sound waves and shock waves to detect arc discharge and mechanical faults inside electric equipment. The transformer is the "heart" equipment of the substation. Taking the transformer as an example, the vibration of the transformer body depends entirely on the vibration of the iron core. The vibration of the iron core can be approximated as the magnetostriction of the silicon steel sheet. The magnetostrictive vibration of the iron core is transmitted to the fuel tank wall through the two paths of the iron core pad and the insulating oil medium, so that the vibration of the fuel tank wall generates sound waves and emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com