Array substrate, preparation method of array substrate and display panel

An array substrate and cross-section technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of abnormal tapping, failure to return to the original position in time, light leakage of the display panel, etc., and achieve the effect of reducing light leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

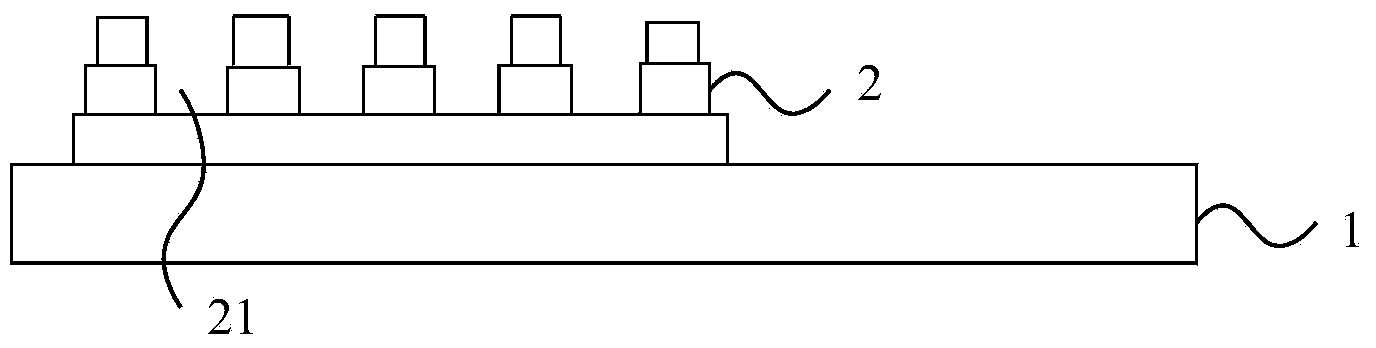

[0042] image 3 A schematic diagram of the structure of the array substrate provided for the embodiment of the present invention, such as image 3 As shown, the array substrate provided by the embodiment of the present invention includes: a spacer pillow 2 for supporting a spacer, and the supporting end of the spacer pillow 2 is provided with at least one concave portion 21 .

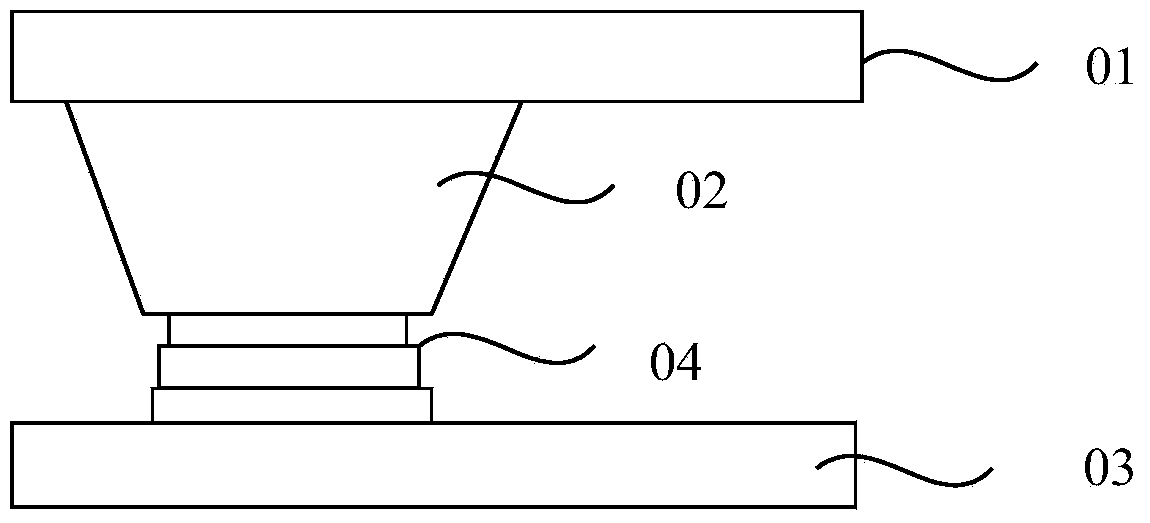

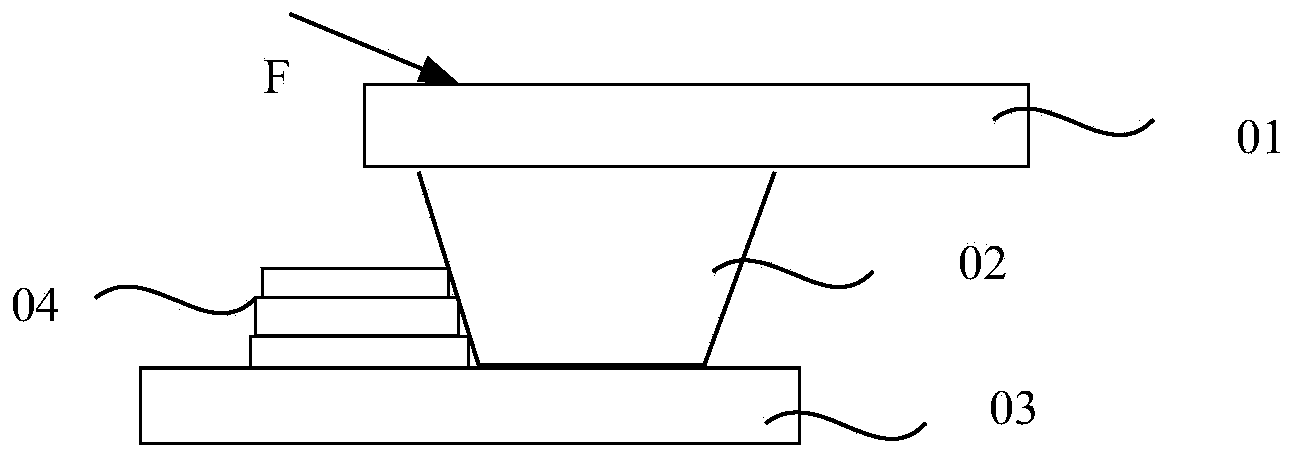

[0043] The array substrate provided by the embodiment of the present invention is applied in a display panel, such as Figure 4 as shown, Figure 4 The schematic diagram of the display panel structure provided by the embodiment of the present invention, the array substrate 1 and the color filter substrate 3 are connected in pairs, the spacer pillow 2 corresponds to the spacer 4 and is used to support the spacer 4, through the array The support end of the spacer pillow 2 provided on the substrate 1 is provided with one or more recesses 21, which can increase the size of the support end of the spacer pi...

Embodiment 2

[0053] An embodiment of the present invention provides a method for preparing an array substrate, including:

[0054] Coating photoresist on the substrate on which the semiconductor layer and the source-drain metal layer have been formed, and performing the first etching to form a spacer pillow;

[0055] A second etch is performed on the spacer pillow, forming a depression on the support end of the spacer pillow.

[0056] In the method for preparing an array substrate provided by the embodiment of the present invention, a spacer pillow provided with at least one groove is formed at the same time as the semiconductor layer and the source-drain metal layer are formed. During the preparation process, there is no need to purchase new ones separately. The mask plate does not need to add new materials, and it will not affect the display effect of the display panel.

[0057] Such as Figure 8a ~ Figure 8i as shown, Figures 8a-8i It is a schematic structural diagram during the pre...

Embodiment 3

[0069] An embodiment of the present invention provides a display panel, such as Figure 4 As shown, it includes a color filter substrate, and also includes the array substrate described in any one of the first embodiment above.

[0070] Based on the above advantages of the array substrate, the display panel provided by the embodiment of the present invention has a better display effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com