Vehicle power battery system and heating management method thereof, and electric vehicle

A power battery and management method technology, which is applied to electric vehicles, electric vehicle charging technology, battery/fuel cell control devices, etc., can solve the problems of reducing battery life and battery damage, so as to reduce battery life and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

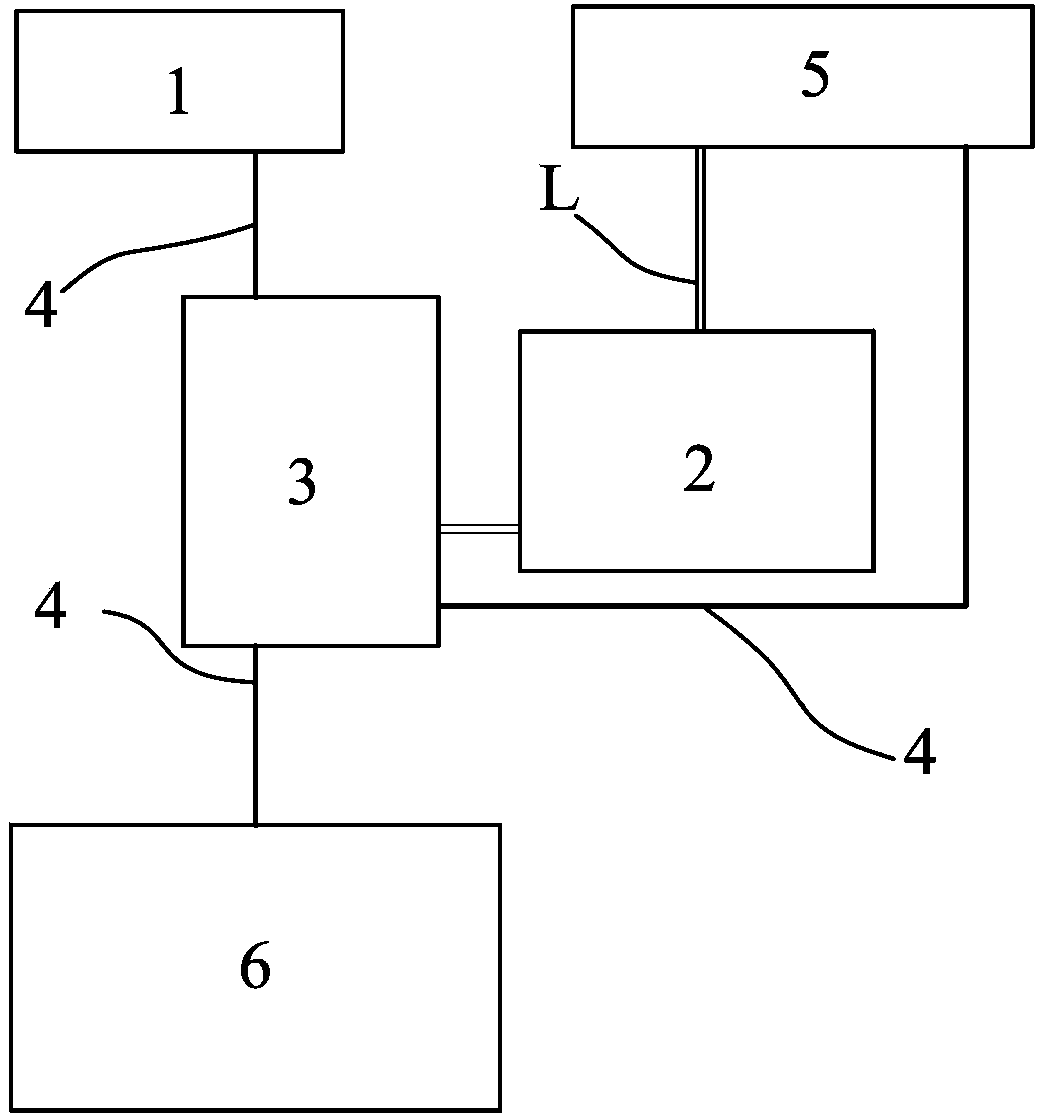

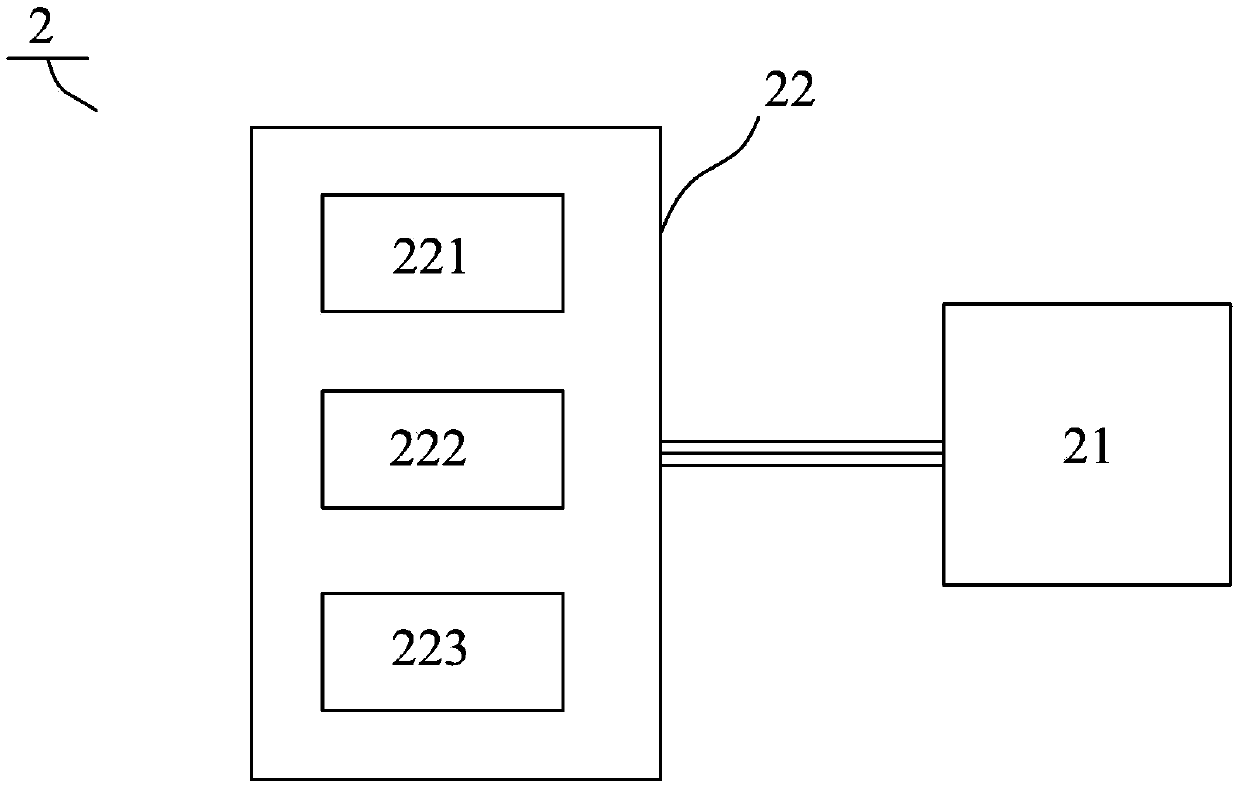

[0036] as follows figure 1 As shown, this example provides a vehicle power battery system, including a lithium-ion battery pack 5 , a heating device 1 , a battery management system 2 , a heating mode selection device 3 , and a charging device 6 .

[0037] The charging device 6, the heating device 1 and the lithium-ion battery pack 5 are electrically connected to each other through a high-voltage wire 4; the so-called electrical connection between the two is connected to each other through a high-voltage wire 4 means that the charging device 6 and the heating device 1 are electrically connected through a high-voltage wire. The charging device 6 is electrically connected to the heating device 1 through a high-voltage wire 4 , and the heating device 1 is electrically connected to the lithium-ion battery pack 5 through a high-voltage wire.

[0038] The heating mode selection device is set between the heating device and the lithium-ion battery pack, the heating device and the charg...

Embodiment 2

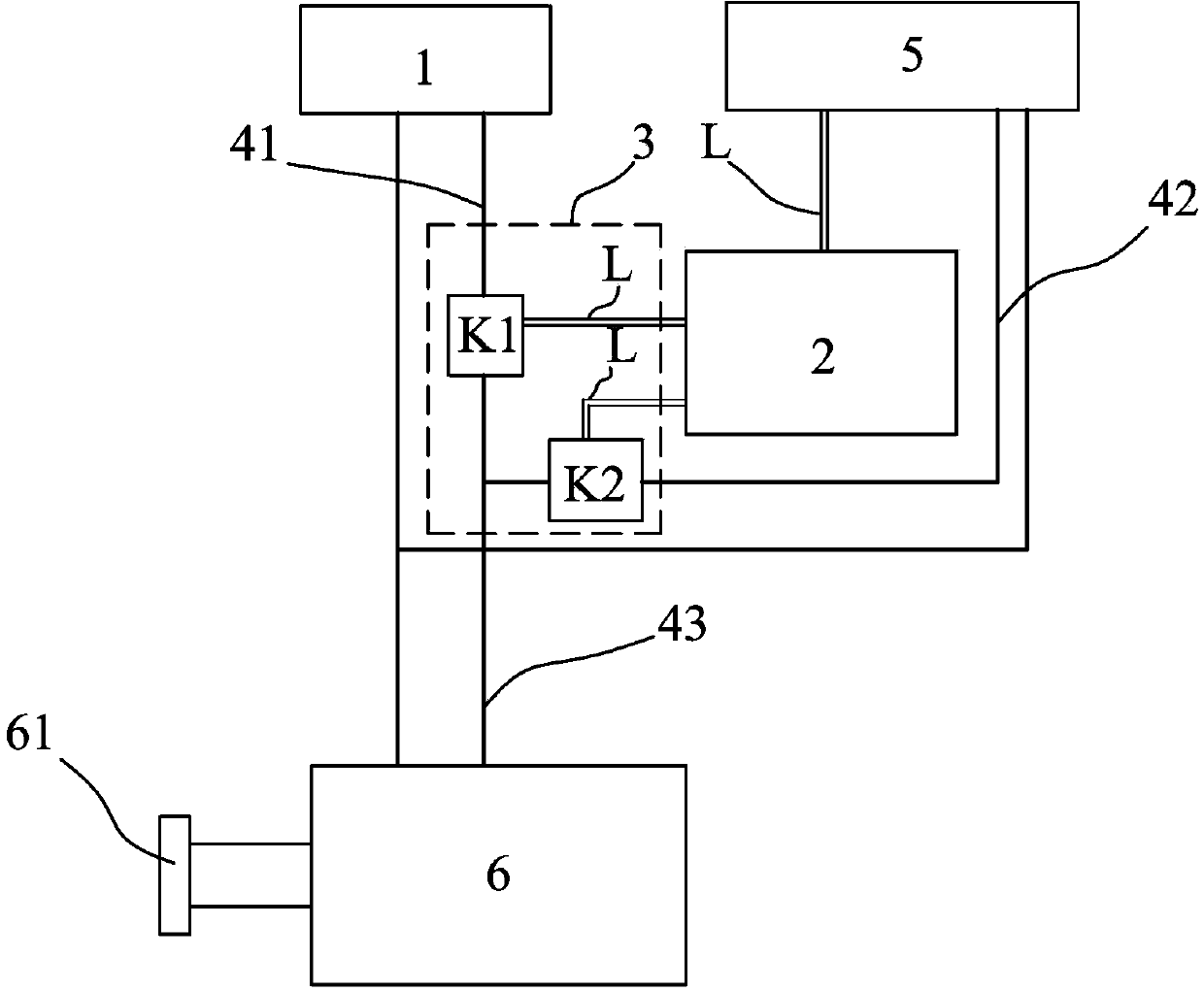

[0047] The embodiment of the present invention also discloses a heating mode selection device 3, such as image 3 As shown, it includes a heating switch K1 and a charging switch K2; the heating switch K1 is set on the high-voltage line 4 between the heating device 1 and the charging device 6, and between the heating device 1 and the lithium-ion battery pack 5, and is used to control the heating device 1 and the charging device 6. The circuit between the heating device 1 and the lithium-ion battery pack 5 is switched on and off. The charging switch K2 is set on the high-voltage line 4 between the lithium-ion battery pack 5 and the charging device 6, the lithium-ion battery pack 5 and the heating device 1, and is used to control the 5 and the circuit break between charging device 6.

[0048] Generally, two high-voltage lines at the positive and negative ends are used for DC high-voltage connection, and the heating switch K1 and the charging switch K2 in this embodiment can be a...

Embodiment 3

[0055] On the basis of Example 1, this example provides another preferred heating mode selection device 3, such as Figure 5 As shown, the heating mode selection device 3 includes a first heating switch K3 and a second heating switch K4; the first heating switch K3 is arranged on the high voltage line between the heating device 1 and the charging device 6, and is used to control the heating device 1 and the charging device 6; the second heating switch K4 is set on the high-voltage line 4 between the heating device 1 and the lithium-ion battery pack 5, and is used to control the circuit switching between the heating device 1 and the lithium-ion battery pack 5. In addition, in this example, a charging switch K2 is set to charge the lithium-ion battery pack 5 through the charging device 6. The charging switch K2 is arranged on the high-voltage line between the lithium-ion battery pack 5 and the charging device 6. It is used to control the on-off of the circuit between the lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com