a filter tank

A technology of washing and filtering, applied in the direction of filtration and separation, gravity filter, loose filter material filter, etc., can solve the problems of high maintenance cost, heavy machine repair workload, high cost, etc., and achieve good backwashing effect, Reduced drainage waste and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable the review committee to have a further understanding of the purpose, features and functions of the present invention, the preferred embodiments are hereby given in detail in conjunction with the drawings as follows:

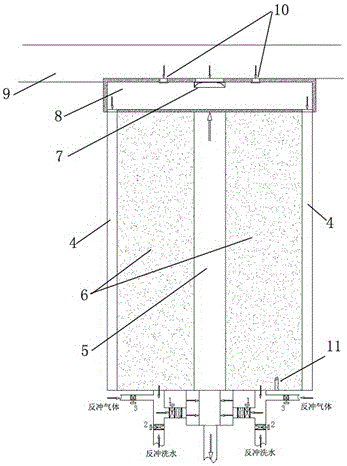

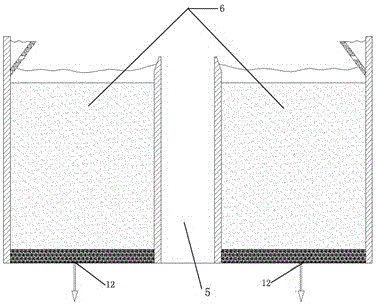

[0021] Figure 1~4 Shown: the present invention is a kind of washing filter tank, mainly comprises V-shaped groove 4, drain channel 5, filter layer 6, airbag valve 7 and backwashing device;

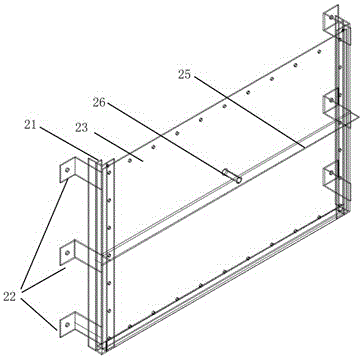

[0022] The V-shaped groove 4 is located on the edge of both sides of the filter, the drain 5 is located in the middle, and the filter layer 6 is arranged between the drain 5 and the V-shaped groove 4; the airbag valve 7 is installed at the junction of the filter grid 8 and the main water inlet Opposite to the center of the drainage channel 5, fine-tuning water inlets 10 are respectively provided on both sides of the air bag valve 7; The valve seat, valve body and protective baffle are composed of three parts. The valve body and the valve seat form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com