Hot press molding equipment

A hot press molding and equipment technology, applied in the field of hot press machinery, can solve the problems of complex processing, scratches on the surface, and long time consumption, and achieve the effects of uniform heating, convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

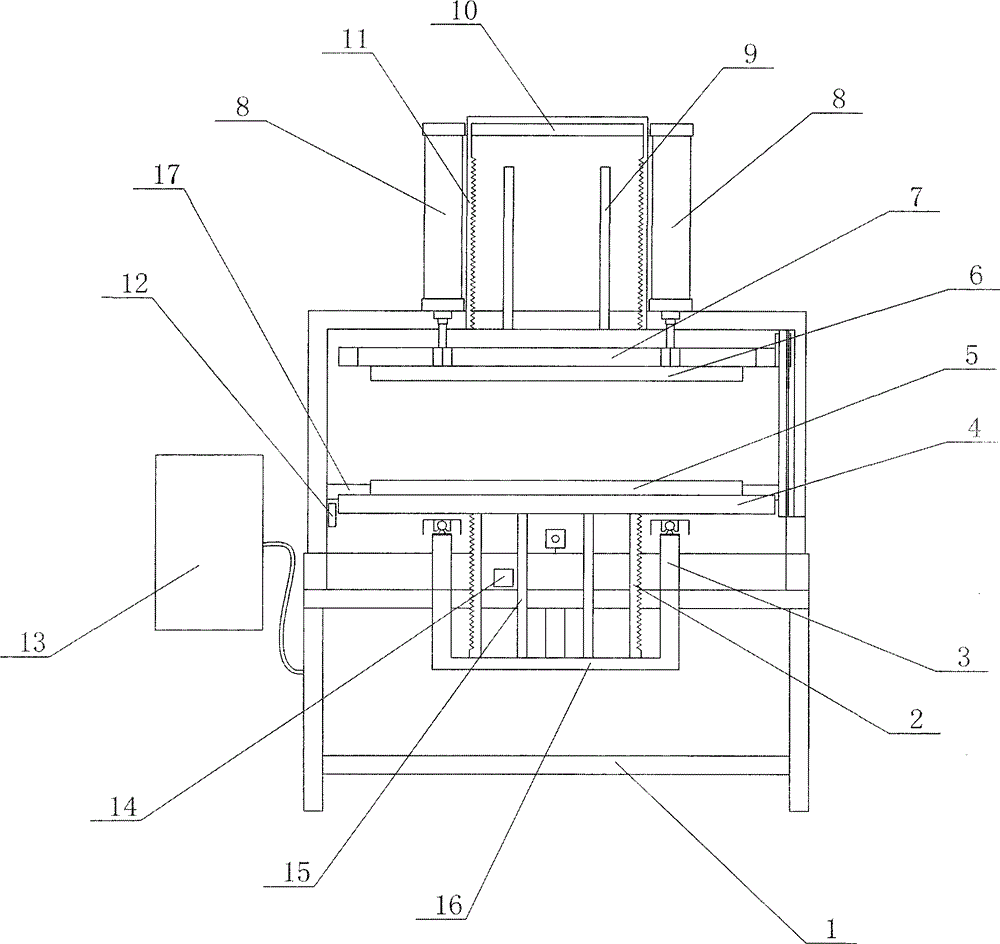

[0017] Such as figure 1 As shown, the thermocompression molding equipment includes a frame 1, a heating device is arranged on the frame 1, an upper worktable 7 and a lower worktable 4 are arranged in the heating device, and upper and lower worktables are respectively arranged on the opposite surfaces of the upper and lower worktables. Mold 6 and lower mold 5. The frame 1 is provided with an upper kinematic mechanism and a lower kinematic mechanism, the upper kinematic mechanism runs through the heating and shaping device and is connected to the upper workbench 7 by transmission, and the lower kinematic mechanism runs through the heating mold device and is connected to the lower workbench 4 by transmission. The upper left side of the frame 1 is provided with a controller 13, the controller 13 is connected with a control panel, and the control panel is provided with several buttons, ammeters and voltmeters. The controller is electrically connected to the heating device, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com