Technology for producing deuterium-depleted water and method for producing deuterium-depleted water thereby

A low-deuterium water and process technology, applied in the field of stable isotopes, can solve the problems of no large-scale mining and utilization, huge mining and transportation costs, limited output, etc., achieving good social and economic benefits, low production costs, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

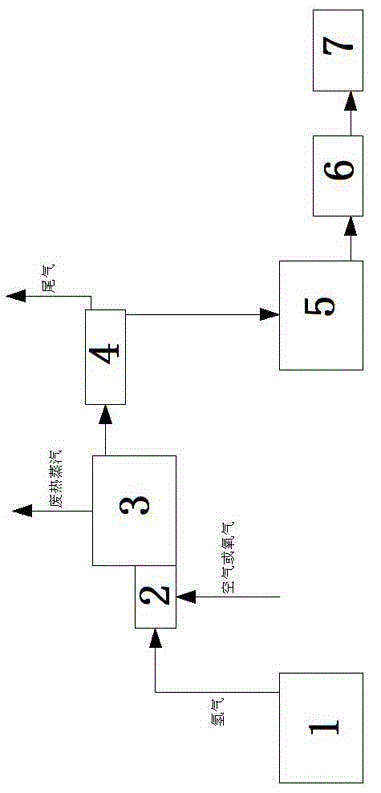

Image

Examples

Embodiment 1

[0030] The hydrogen from the chlor-alkali electrolytic cell 1 is washed with water, cooled and enters the hydrogen-burning boiler 3 for combustion reaction with the oxygen in the air, and the heat released is used to produce steam for heating; the water vapor and residual air produced by the hydrogen combustion are cooled and condensed -Recooling to obtain crude deuterium-depleted water, which is purified by a water purification system, bottled and packaged to obtain commercial deuterium-depleted water.

Embodiment 2

[0032] The hydrogen gas from the chlor-alkali electrolytic cell 1 is washed with water, cooled and enters the hydrogen-burning boiler and pure oxygen for combustion reaction, and the heat is released to produce steam for heating; the water vapor generated by the hydrogen combustion is cooled-condensed to obtain crude deuterium-depleted water, which is passed through water After purification by the purification system, it is bottled and packaged to obtain commercial deuterium-depleted water.

[0033] The invention uses hydrogen and oxygen by-products in the chlor-alkali industry for combustion reaction, and the produced water is cooled and condensed to obtain deuterium-depleted water. According to the principle of isotope separation, the deuterium content in the hydrogen by-product of the chlor-alkali industry is 40-60ppm, which can produce extremely high-value deuterium-depleted water. The invention has low energy consumption and low production cost, and can realize industrial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com