A kind of preparation method of sico micron ceramic cross

A cross, ceramic technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve good stability, less equipment investment, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

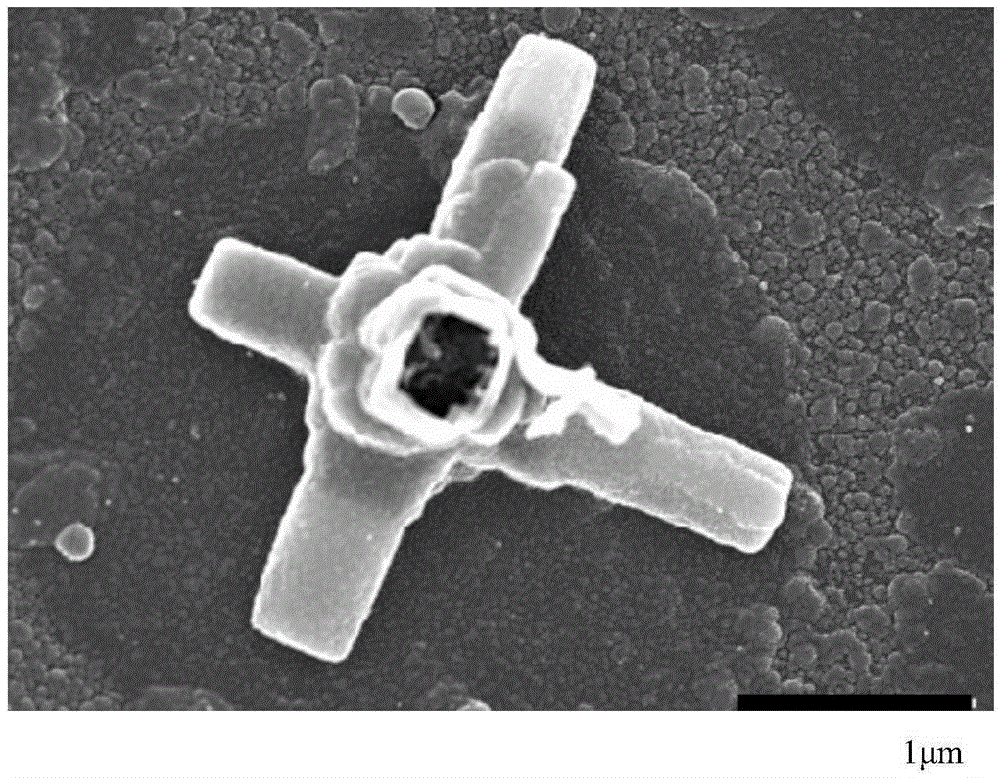

[0023] The polytetrafluoroethylene disks were cleaned with ethanol and sonicated, then dried in an oven for later use. Weigh 0.8 g of F127, dissolve it in 5 ml of xylene, seal it, and stir for 3 hours to obtain mixed solution A. Add 0.8 g of polyvinylsilazane and 0.032 g of dicumyl peroxide to another container, dissolve in 5 ml of isopropanol, seal it quickly, and stir it magnetically for 3 hours to obtain a mixed solution B. Then the solutions in the two containers were mixed and sealed quickly, the containers were protected from light, and the stirring time was continued for 24 hours to obtain the mixed solution C. Pour the mixed solution C into a polytetrafluoroethylene tray kept warm at 50°C for 48 hours, and obtain a transparent film after the solvent evaporates. Put the film into an oven at 130°C for thermal crosslinking for 40 minutes, the film changes from colorless and transparent to light yellow, and it is taken out for release. After defilming, the film was place...

Embodiment 2

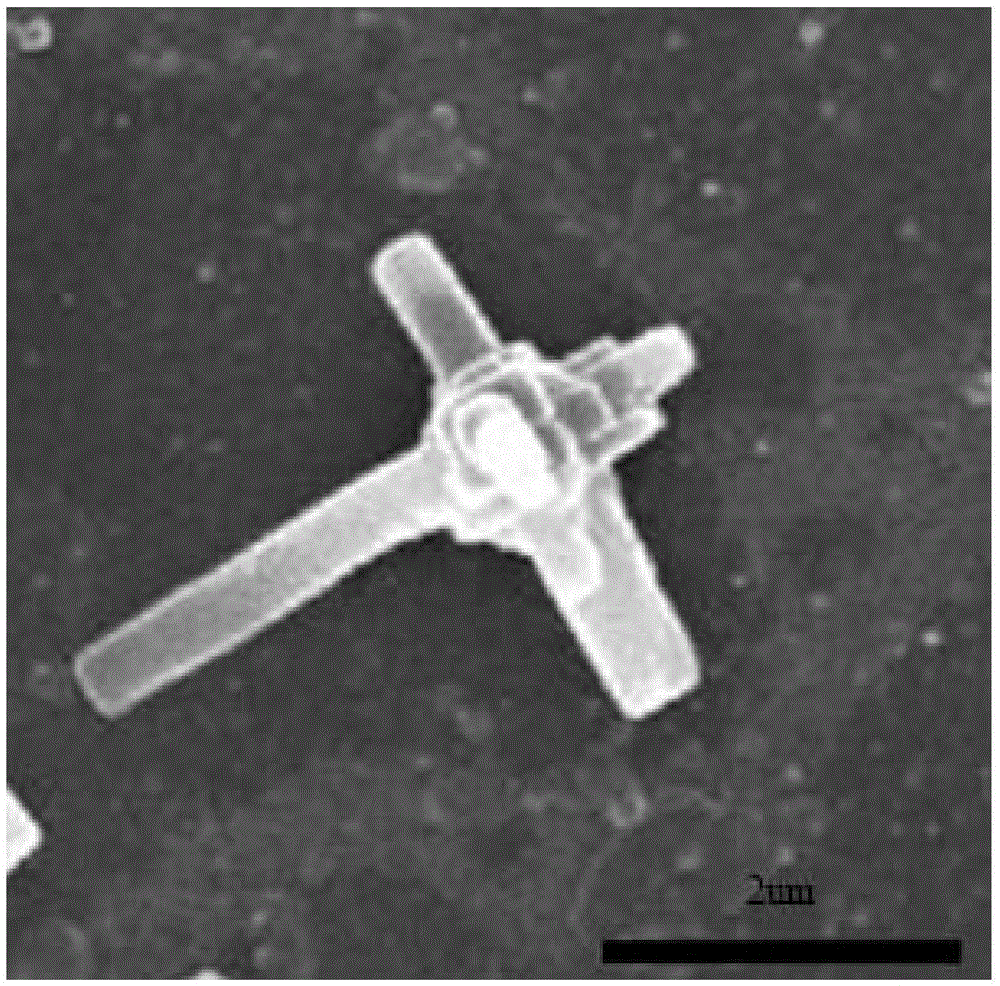

[0026] The polytetrafluoroethylene disks were cleaned with ethanol and sonicated, then dried in an oven for later use. Weigh 0.8g of F127, dissolve it in 5ml of xylene and seal it, stir for 2 hours to obtain mixed solution A. Add 0.8 g of polyvinylsilazane and 0.032 g of dicumyl peroxide to another container, dissolve in 5 ml of isopropanol, seal it quickly, and stir it magnetically for 2 hours to obtain a mixed solution B. Then the solutions in the two containers were mixed and sealed quickly, the containers were protected from light, and the stirring time was continued for 18 hours to obtain the mixed solution C. Pour the mixed solution C into a polytetrafluoroethylene tray kept at 50°C for 36 hours, and obtain a transparent film after the solvent evaporates. Put the film into an oven at 130°C for thermal crosslinking for 40 minutes, the film changes from colorless and transparent to light yellow, and it is taken out for release. After defilming, the film was placed on gra...

Embodiment 3

[0029] The polytetrafluoroethylene disks were cleaned with ethanol and sonicated, then dried in an oven for later use. Weigh 0.8 g of F127, dissolve it in 5 ml of xylene and seal it, stir for 4 hours to obtain mixed solution A. Add 0.8 g of polyvinylsilazane and 0.032 g of dicumyl peroxide to another container, dissolve in 5 ml of isopropanol, seal it quickly, and stir it magnetically for 4 hours to obtain a mixed solution B. Then the solutions in the two containers were mixed and sealed quickly, the containers were protected from light, and the stirring time was continued for 24 hours to obtain the mixed solution C. Pour the mixed solution C into a polytetrafluoroethylene tray kept warm at 50°C for 60 hours, and obtain a transparent film after the solvent evaporates. Put the film into an oven at 130°C for thermal crosslinking for 40 minutes, the film changes from colorless and transparent to light yellow, and it is taken out for release. After defilming, the film was placed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com