Preparation method of octenyl succinic acid water-soluble starch ester

A technology of octenyl succinic acid and water-soluble starch, applied in the field of food chemistry, can solve the problems of decreased substitution degree, increase of octenyl succinic acid residue, excessive octenyl succinic acid residue, etc., so as to reduce the residual amount , improve the replacement efficiency, the effect of improving the replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Grind 10g of dry barite and pass it through a 80-mesh sieve, then add 0.3g of octenyl succinic anhydride under stirring conditions, and mix well;

[0027] 2) Dissolve 10g of water-soluble waxy cornstarch in 10g of water, add the starch solution dropwise to the mixture obtained in step 1) within 2 hours at a constant speed, the stirring speed is 500 rpm, adjust the pH value to 7.5, wait for the pH Continue to react for 2 hours after the value is stable, and control the temperature at 40°C throughout the process;

[0028] 3) Adjust the pH value of the reaction solution obtained in step 2) to 2, and shake for 5 hours;

[0029] 4) Centrifuge the solution obtained in step 3), collect the supernatant, adjust the pH value to 6, and freeze-dry to obtain 9.83 g of octenyl succinate of water-soluble waxy corn starch;

[0030] 5) Collect the centrifuged solid in step 4), dry at 130° C. for 2 hours, and burn for 1 hour to obtain regenerated dry barite.

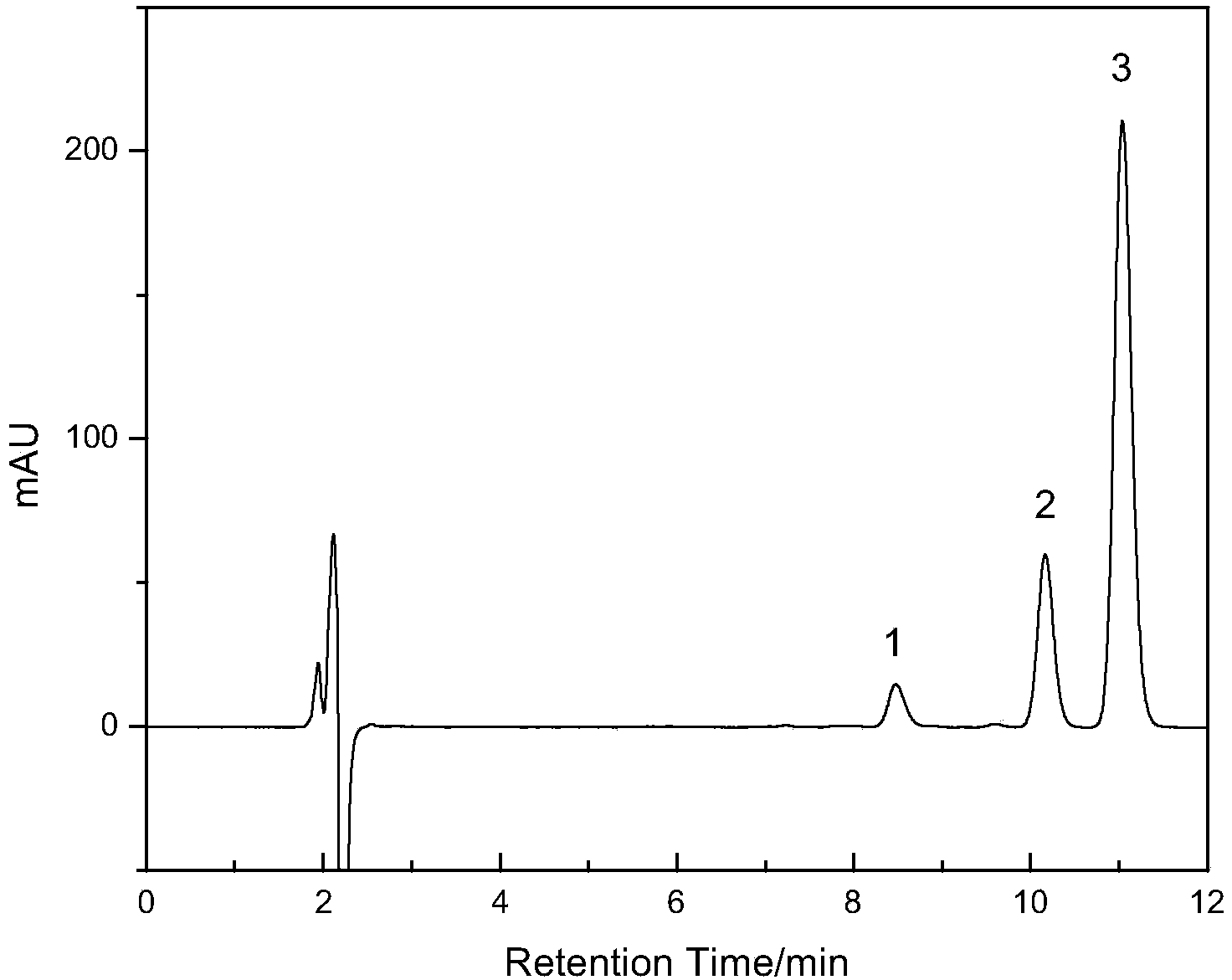

[0031] After testing, ...

Embodiment 2

[0049] 1) Grind 2g of dry natural zeolite and pass through a 140-mesh sieve, then add 0.1g of octenyl succinic anhydride under stirring conditions, and mix well;

[0050] 2) Dissolve 10g of water-soluble corn starch in 30g of water, then add the starch solution dropwise to the mixture obtained in step 1) within 0.5 hours at a constant speed, the stirring speed is 100 rpm, adjust the pH value to 9, and wait for the pH value Continue to react for 0.5 hours after stabilization, and control the temperature at 20°C throughout the process;

[0051] 3) Adjust the pH value of the reaction solution obtained in step 2) to 5, and shake for 0.5 hours;

[0052] 4) Centrifuge the material obtained in step 3), collect the supernatant, adjust the pH value to 7, and then spray dry to obtain 9.74g of octenyl succinate of water-soluble cornstarch;

[0053] 5) Collect the centrifuged solid in step 4), dry at 110° C. for 4 hours, and then burn for 0.5 hour to obtain regenerated dry natural zeolit...

Embodiment 3

[0056] 1) Grind 5g of dry kaolin and pass through a 130-mesh sieve, then add 0.2g of octenyl succinic anhydride under stirring conditions, and mix well;

[0057] 2) Dissolve 10g of water-soluble wheat starch in 20g of water, then add the starch solution dropwise to the mixture obtained in step 1) within 1.5 hours at a constant speed, the stirring speed is 200 rpm, adjust the pH value to 8, wait for the pH value Continue to react for 1.5 hours after stabilization, and control the temperature at 25°C throughout the process;

[0058] 3) Adjust the pH value of the reaction solution obtained in step 2) to 3, and shake for 1.5 hours;

[0059] 4) Centrifuge the material obtained in step 3), collect the supernatant, adjust the pH to 6.5, and then spray dry to obtain 9.82 g of octenyl succinate of water-soluble wheat starch;

[0060] 5) Collect the centrifuged solid in step 4), dry at 120° C. for 3 hours, and then burn for 1 hour to obtain regenerated dry kaolin.

[0061] After detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com