A method for preventing the pH value from dropping during the production and storage of maltose syrup

A maltose syrup and production process technology, applied in the field of starch sugar industry, can solve the problems of unfavorable energy saving and consumption reduction, high regeneration cost, and difficult regeneration, so as to improve product quality and stability, low resin treatment cost, and stable pH value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

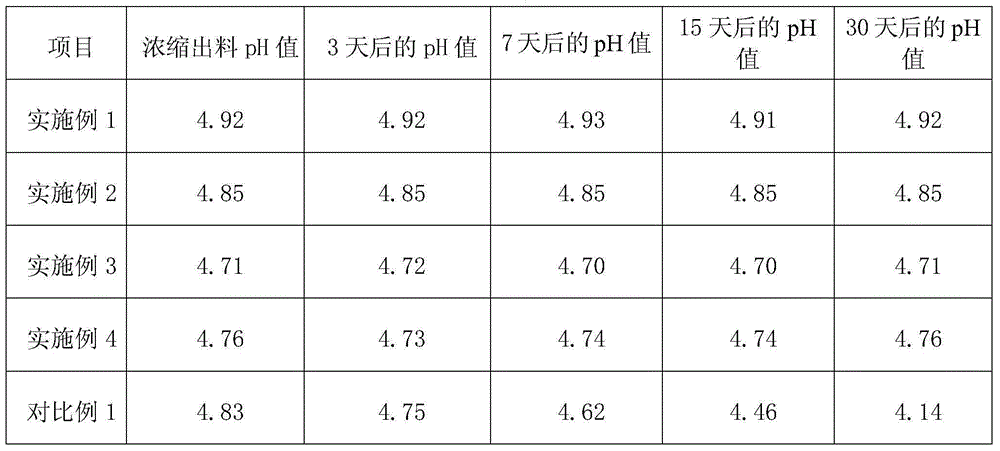

Examples

Embodiment 1

[0024] A method for preventing the pH value from falling during the production and storage of maltose syrup includes the following steps:

[0025] (1) Reduce the temperature of the decolorized and filtered sugar liquid material in the maltose syrup production process to below 50°C, and then perform preliminary ion exchange with a strong acid cation exchange resin and a weakly basic anion exchange resin. The sugar liquid material after preliminary ion exchange Pass into a strongly basic anion exchange resin column containing 201×4 anion exchange resin at a flow rate of 5bv / h. The amount of 201×4 anion exchange resin is 1 / 10 of the hourly feed liquid flow;

[0026] (2) The material flowing out of step (1) strongly basic anion exchange resin column is passed into the pH adjustment column containing 001×7 resin at a flow rate of 5 bv / h. The amount of 001×7 resin is the feed liquid flow rate per hour 1 / 20 of it; to control the discharge pH value of 4.5, and then enter the concentration ...

Embodiment 2

[0028] The method for preventing the pH value from falling during the production and storage of maltose syrup as described in Example 1, the difference is:

[0029] The amount of 201×4 anion exchange resin is 1 / 2 of the hourly material flow rate; the amount of 001×7 resin is 1 / 10 of the hourly material liquid flow rate;

Embodiment 3

[0031] (1) Reduce the temperature of the decolorized and filtered sugar liquid material in the maltose syrup production process to below 50°C, and then perform preliminary ion exchange with a strong acid cation exchange resin and a weakly basic anion exchange resin. The sugar liquid material after preliminary ion exchange Pass into the strongly basic anion exchange resin column of D201 resin at a flow rate of 8bv / h. The amount of D201 resin is 1 / 10 of the hourly feed liquid flow;

[0032] (2) The material flowing out from step (1) strongly basic anion exchange resin column is passed into the pH adjustment column containing D001 resin at a flow rate of 8 bv / h. The amount of D001 resin is 1 / 20 of the feed liquid flow per hour , In order to control the discharge pH value of 4.8, and then enter the concentration process in the maltose syrup production process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com