an incinerator system

An incinerator and furnace technology, applied in the field of incinerator systems, can solve the problems of agglomeration of incinerators, pollute the surrounding environment, serious heat energy loss, etc., and achieve the effect of ensuring recycling, avoiding agglomeration in the furnace, and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

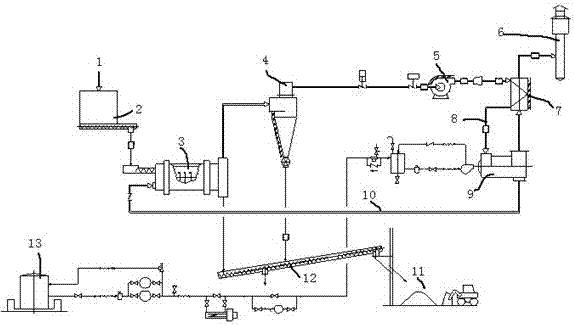

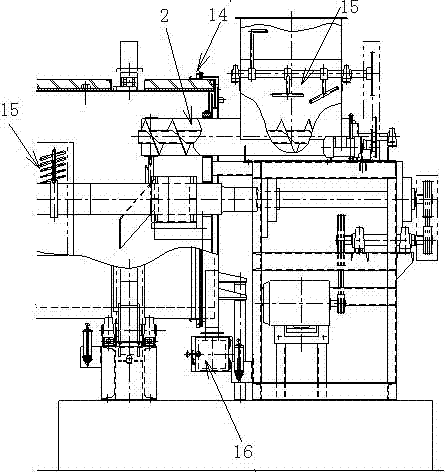

[0024] Attached below Figure 1-4 The present invention is further described with embodiment. But the protection scope of the present invention is not limited thereto.

[0025] Such as figure 1 Shown, it has shown the specific structure of the incinerator system of the present invention, and this incinerator system comprises feed port 1, incinerator 3, ribbon feeder 2, cyclone separator 4, exhaust fan 5, direct fire furnace 9. Heat exchanger 7, screw conveyor 12 and oil tank 13, wherein one end of the feed pipe on the incinerator 3 is connected with a ribbon feeder 2, and the ribbon feeder 2 is set to be connected to the feed port 1, when After the incinerated materials to be incinerated are fed into the feed port 1, the ribbon feeder 2 will send the incinerated materials to the incinerator 3 through the internal spiral ribbon. When feeding, the cold air at the feeding port can be effectively blocked from further entering into the incineration cylinder of the incinerator 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com