Device and method for rapidly detecting optical grating auxiliary gap at high precision

A grating pair, high-precision technology, used in measuring devices, electrical devices, instruments, etc., can solve the problems of low measurement accuracy, large structure size, low efficiency, etc., and achieve distance measurement, high-precision detection, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

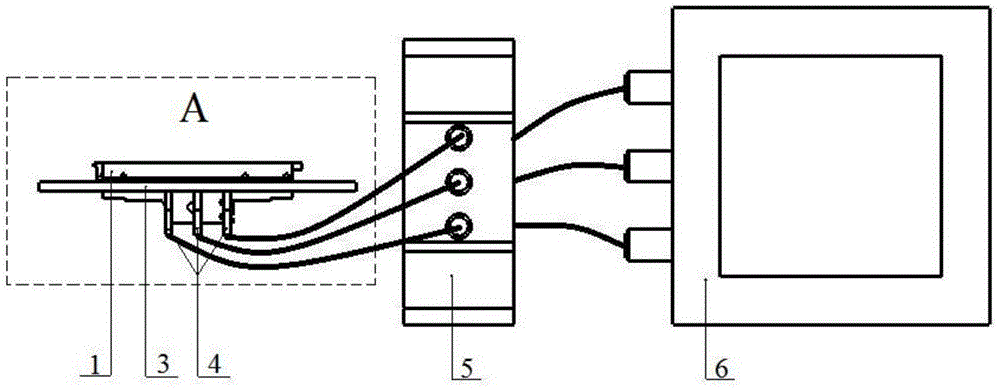

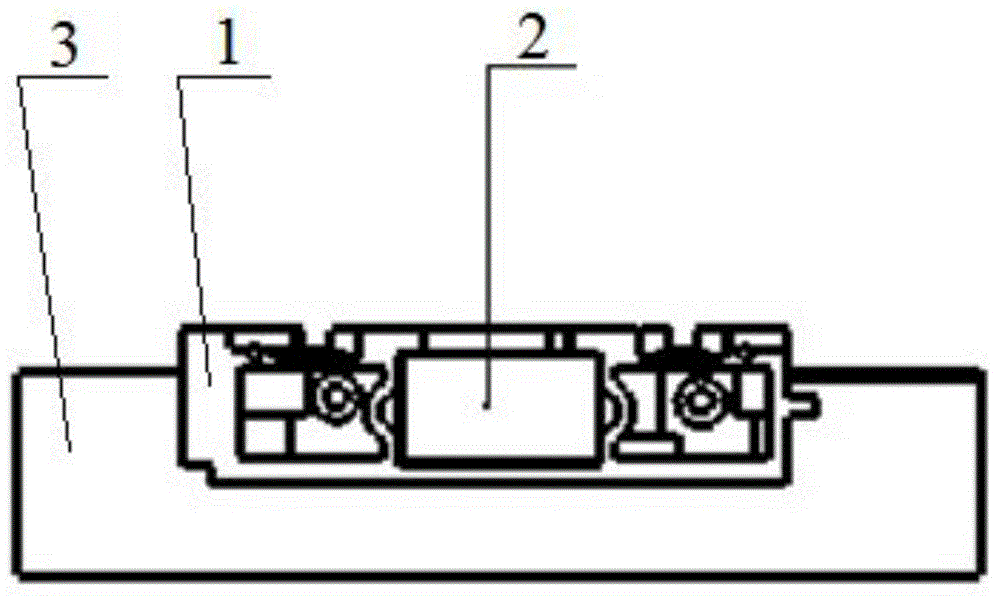

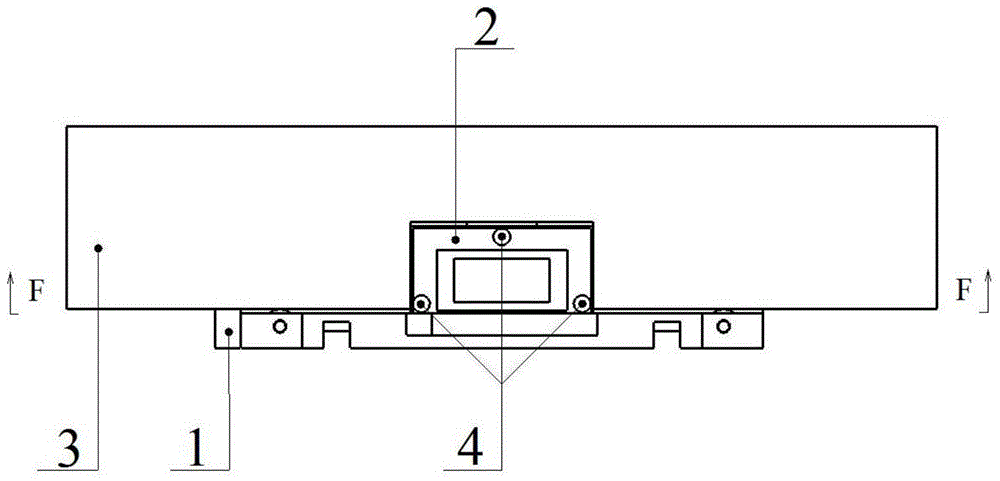

[0019] like figure 1 As shown, the device for high-precision and rapid detection of grating sub-gap of the present invention includes a carriage 1, an indicating grating 2, a main grating 3, three eddy current sensors 4, a grating displacement measurement system 5 and a digital display 6. like figure 2 As shown, the indicating grating 2 is glued and fixed on the carriage 1, and then the carriage 1 is placed on the main grating 3, and the plane where the indicating grating 2 is located and the plane where the main grating 3 is located are parallel to each other. like image 3 As shown, three eddy current sensors 4 are installed below the indicating grating 2, distributed in an isosceles triangle with the largest area, as shown in Figure 4 As shown, the three probes of the three eddy current sensors 4 are on the same plane, and this plane can be flush with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com