Water-cooled packaging structure of optical fiber beam combiner

An optical fiber combiner and packaging structure technology, applied in the field of water-cooled packaging structure, can solve the problems of heat consumption, low heat conduction efficiency, affecting the maximum working power of the device, etc., and achieve the effect of simple structure, improved working power and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

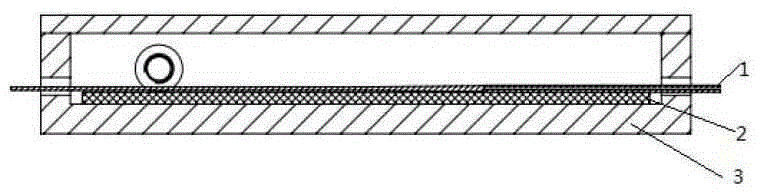

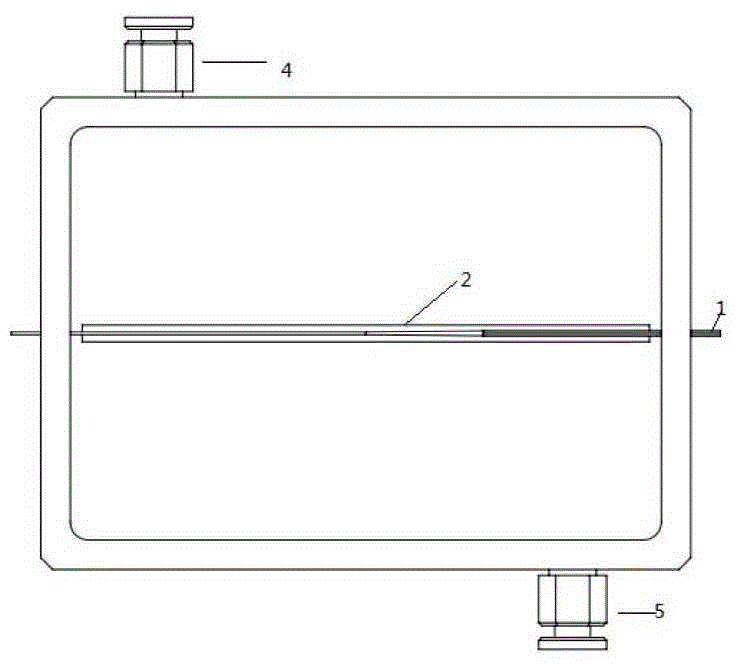

[0013] figure 1 and figure 2 A specific embodiment of the invention is shown. The water-cooled packaging structure of the fiber combiner proposed by the present invention includes: a combiner optical fiber 1 , a base plate 2 and a sealing box 3 . The opposite side of the sealing box is provided with an optical fiber inlet and outlet, the optical fiber 1 of the beam combiner is fixed on the substrate 2 with optical glue, and the substrate is fixed in the sealing box 1 with optical glue. The sealed box body is also provided with a liquid inlet and outlet and is respectively connected with a water circulation device, and the optical fiber melting part of the beam combiner is soaked in circulating water.

[0014] In an embodiment of the present invention, a (6+1)×1 type beam combiner is fabricated, the pump input fiber is 200 / 220 0.22NA, and the signal input and output signal fibers are 30 / 600 0.06 / 0.46NA. When packaging, the beam combiner optical fiber 1 is fixed on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com