Portable vertical bamboo flute

A portable, hole-drilling technology, applied in the field of musical instruments, can solve the problems of inability to wash with water, easy to stink and mold, and accumulate dirt, etc., and achieve the effects of excellent quality, less labor input, and stable molding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

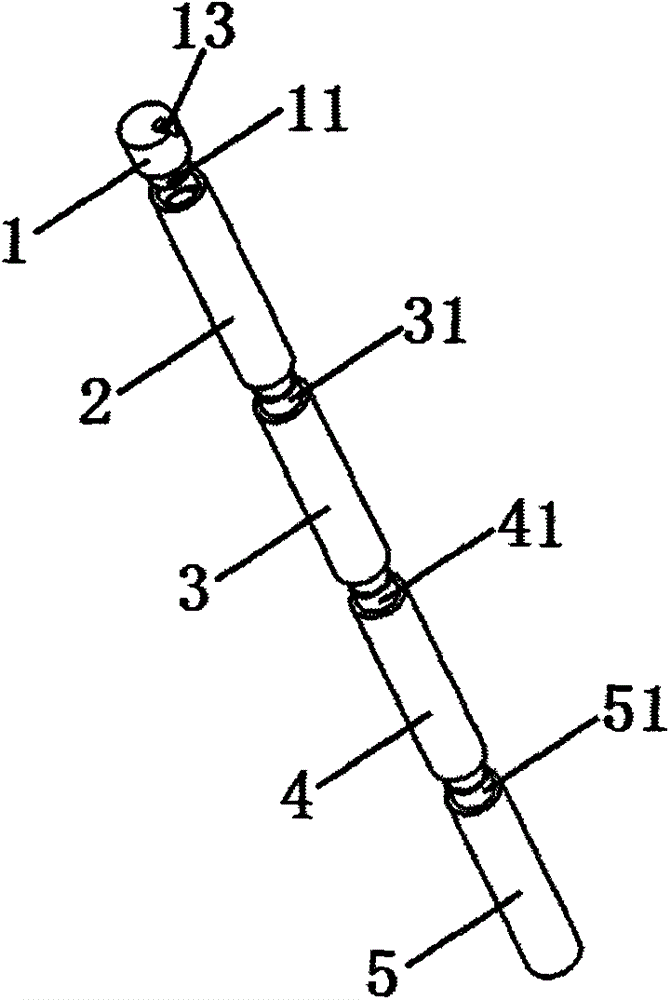

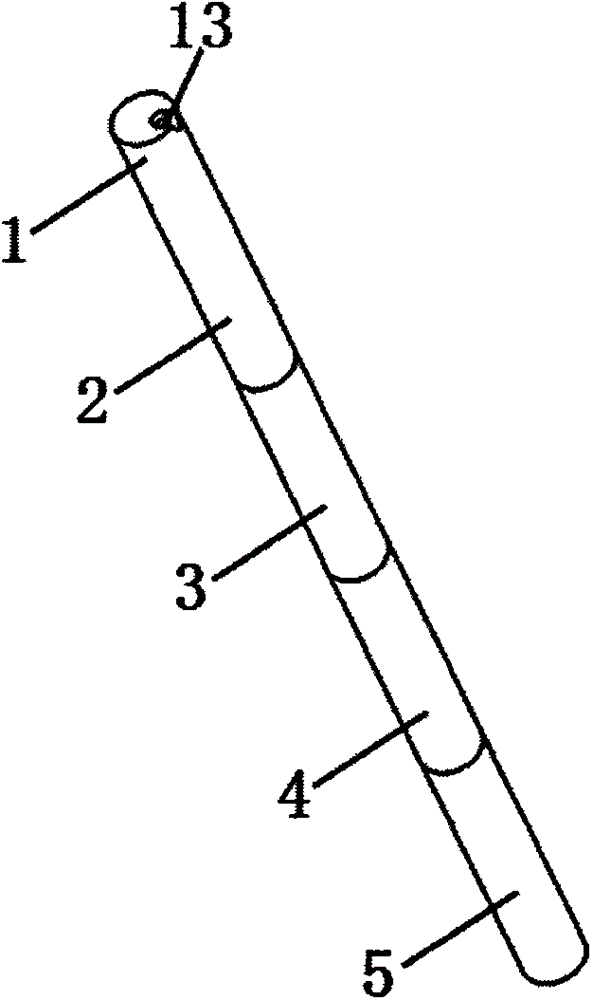

[0040] please see Figure 1 to Figure 3 , a portable hole flute, characterized in that: it includes a flute head 1 and a pipe body connected to the flute head, the flute head is in the shape of a cylinder with one end open, the flute head has a hollow flute cavity 12 inside, and the other end of the flute head It is closed and has a mouthpiece 13 at this end, and the mouthpiece communicates with the mouthpiece cavity; one end of the mouthpiece has a mouthpiece connecting ring 11, and the outer diameter of the mouthpiece connecting ring is smaller than the outer diameter of the mouthpiece; the pipe body consists of four The connecting tubes are connected in sequence, and each connecting tube has an air hole passing through along its own axis, and all the air holes are connected. The air hole of the connecting tube at the connection with the mouthpiece can accommodate the mouthpiece connection. ring; the mouthpiece is formed by injection molding; the pipe body is formed by injec...

Embodiment 2

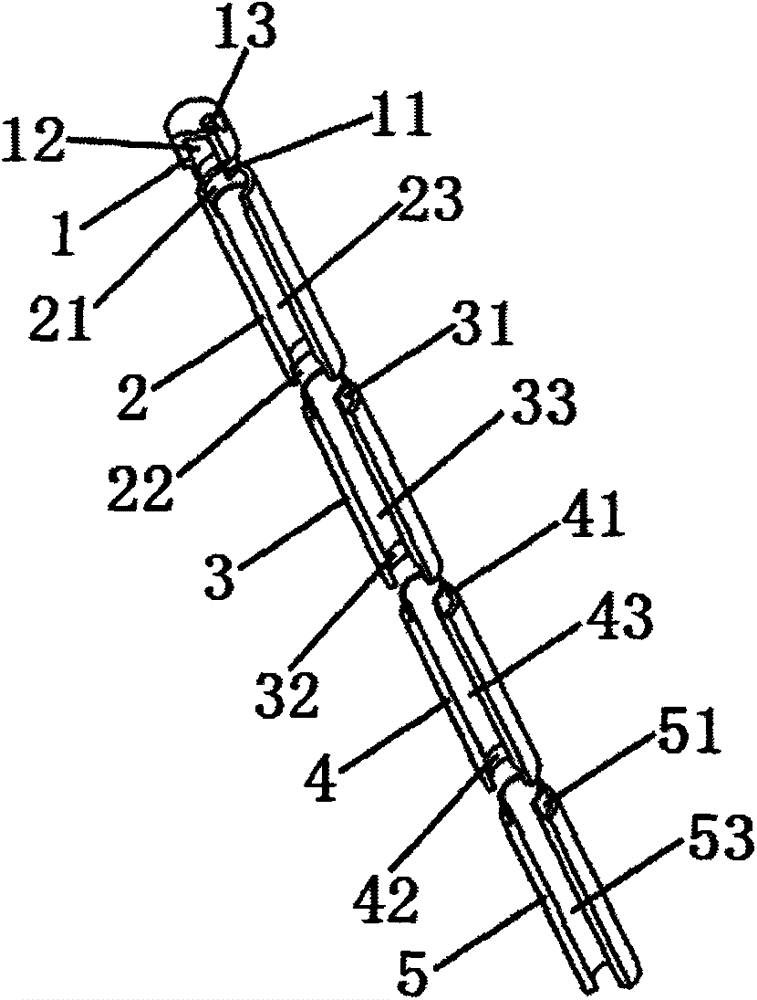

[0042] please see Figure 4 to Figure 6 , and refer to Figure 1 to Figure 3 , the portable flute, basically the same as the implementation example 1, the difference is that: the inside of the two-section pipe 2 has a first air passage hole 23 penetrating along the axis of the two-section pipe, the upper end of the first air passage hole is a containment ring hole 21, and the diameter of the containment ring hole is Greater than the diameter of the middle part of the first air passage hole, the ring hole can accommodate the mouthpiece connecting ring, the lower end of the first air passage hole is the first connection hole 22, and the diameter of the first connection hole is greater than the diameter of the middle part of the first air passage hole; The lower end of the upper section has a protruding two-section tube bamboo strip 24; the inside of the upper section tube 3 has a second air hole 33 penetrating along the axis of the upper section tube, and the upper end of the up...

Embodiment 3

[0048] please see Figure 7 , and refer to Figure 1 to Figure 3 , the portable flute, basically the same as the implementation example 1, the difference is that: the inner wall of the second pipe forming the first connecting hole 22 has a first positioning groove; the outer wall of the connecting column 31 of the upper pipe has a first positioning bar 35; The inner wall of the upper section pipe of the two connection holes 32 has a second positioning groove; the outer wall of the lower section pipe connecting column 41 has a second positioning bar 44; the inner wall of the lower section pipe forming the third connection hole 42 has a third positioning groove; The outer wall of the tailpipe connecting column 51 has a third positioning bar 54; the first positioning bar can be inserted into the first positioning slot, the second positioning bar can be inserted into the second positioning slot, and the third positioning bar can be inserted into the third positioning slot Middle;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com