Environment-friendly clean prefabricated branch cable and manufacturing method thereof

A branch cable and prefabricated branch technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of branch cables, such as powerlessness, and achieve the effect of consistent cable main body, superior insulation performance, and consistent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

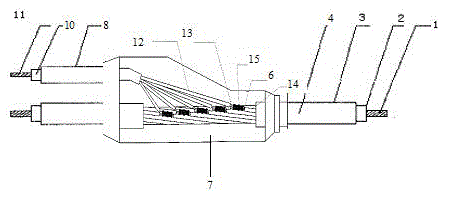

[0026] An environmentally friendly and clean prefabricated branch cable, which consists of a main cable, a branch cable, a "C"-shaped sleeve and a molded branch joint. Rubber outer sheath 3, branch cable conductor 11 is followed by branch cable silicone rubber insulating layer 10, branch cable silicone rubber outer sheath 8, trunk cable silicone rubber insulating layer 2 and trunk cable silicone rubber outer sheath 3 There are talcum powder with release agent and non-woven fabric wrapped around the main cable, and the connection between the main cable conductor 1 and the branch cable conductor 11 is respectively stripped of the main cable silicone rubber outer sheath 3, the main silicone rubber insulating layer 2 and the branch cable silicone rubber outer sheath. Sheath 8, branch silicone rubber insulating layer 10, the junction of main cable conductor 1 and branch cable conductor 11 is crimped by C-shaped clip 6 with raised ridges, the junction of trunk cable conductor 1 and b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com