200-level impulse-voltage-resistant composite enameled wire and production method

A production method and anti-pulse technology, used in circuits, insulated cables, electrical components, etc., can solve problems such as shortening motor life and motor insulation problems, and achieve improved service life, good corona resistance, and improved chemical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

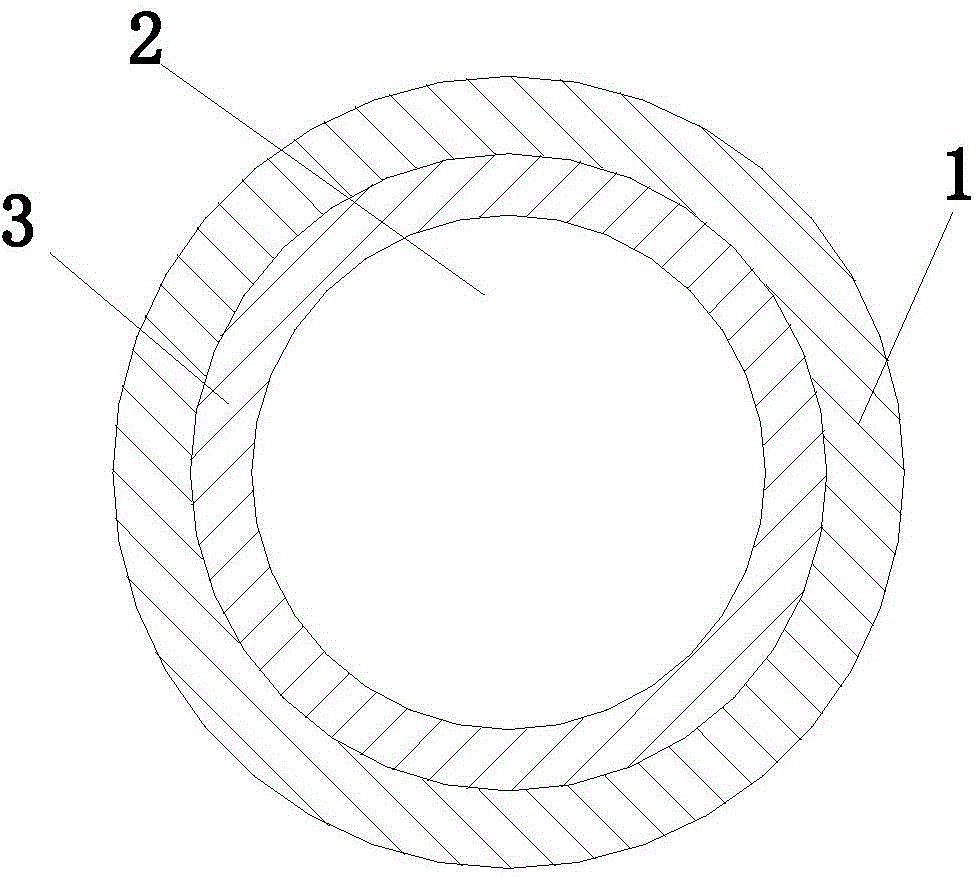

[0014] Example. Class 200 anti-pulse voltage composite enameled wire, composed of figure 1 As shown, it includes a copper round wire 2, and the surface of the copper round wire 2 is sequentially provided with a frequency conversion paint layer 3 and a polyamideimide paint layer 1 from the inside to the outside, and the frequency conversion paint layer 3 includes 8 polyamide-imide paint layers Esterimide paint layer, the thickness of each polyesterimide paint layer is 0.005mm.

[0015] Preferably, the polyesterimide paint is Dupont polyesterimide paint.

[0016] The diameter of the copper round wire 2 is 1.240-1.255mm, and the minimum thickness of the insulating varnish layer formed by compounding the frequency conversion varnish layer 3 and the polyamide-imide varnish layer 1 is 0.067mm.

[0017]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com