A cage culture automatic feeding platform system and operation method

A net cage culture and platform technology, which is applied in fish farming, application, animal husbandry, etc., can solve the problems that hinder the development of large cage culture, high cost of breeding, and high labor intensity of workers, so as to reduce feed carrying and The number of people fed, which is conducive to centralized monitoring and management, and the effect of saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with accompanying drawing.

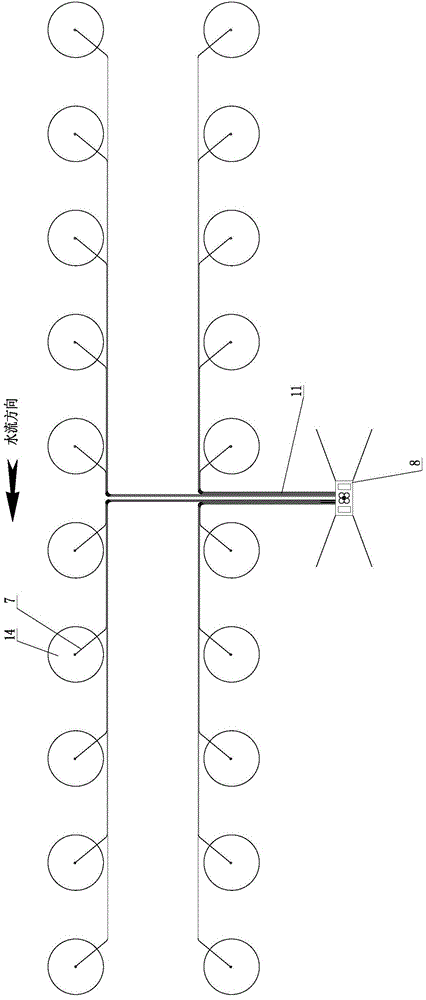

[0047] Such as figure 1 Shown, the culture net cage 14 layout on the culture waters is parallel two rows, quantity 20, and culture net cage 14 is double floating tube type circular net cage, and net cage girth is 100 meters, and net depth is 15 meters~20 meters, The distance between the 14 centers of 2 rows of cultured net cages is 90 meters, and the distance between the 14 centers of the same row of cultured net cages is 60 meters. Throwing and feeding platform 8 is moored on the breeding waters outside two rows of breeding net cages 14, and there is a group of breeding net cages 14 respectively on both sides of feeding platform 8, and each group of breeding net cages 14 includes 2 rows and 5 rows of 10 breeding net cages 14 .

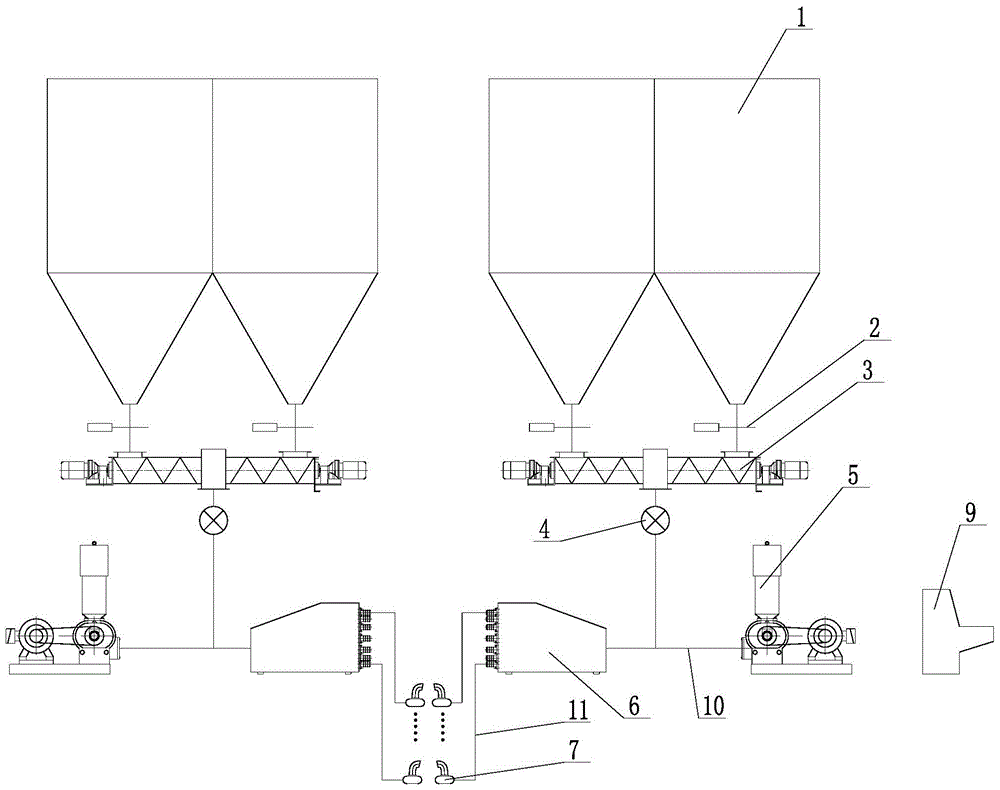

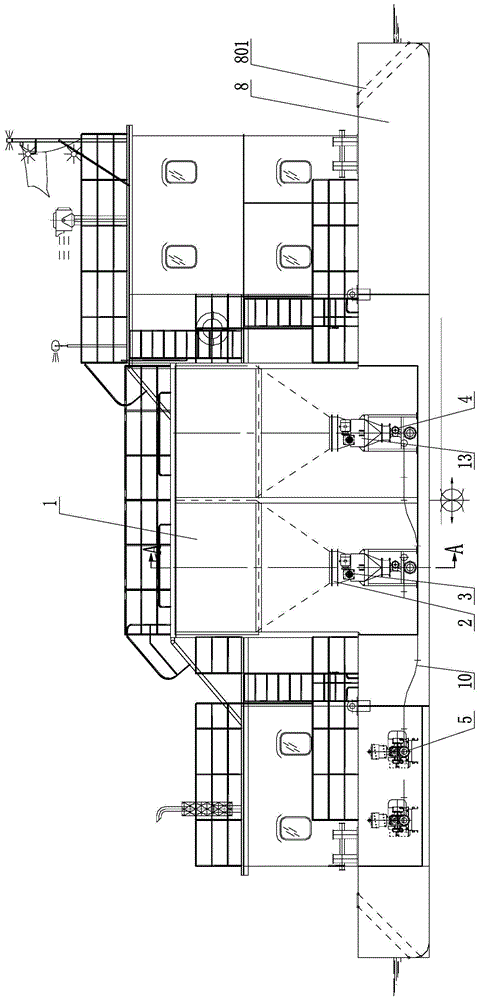

[0048] Such as Figure 3-4 As shown, in the center of the rectangular floating body hull of the feeding platform 8, the quadruple feed bins 1 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com