Novel desulfurization, denitrification, decarburization and dust removal purification combined device for coal-fired flue gas

A coal-fired flue gas, desulfurization and denitrification technology, which is applied in the direction of combined devices, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of fan water corrosion, wet purification resistance, blockage, etc., to improve the purification effect, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

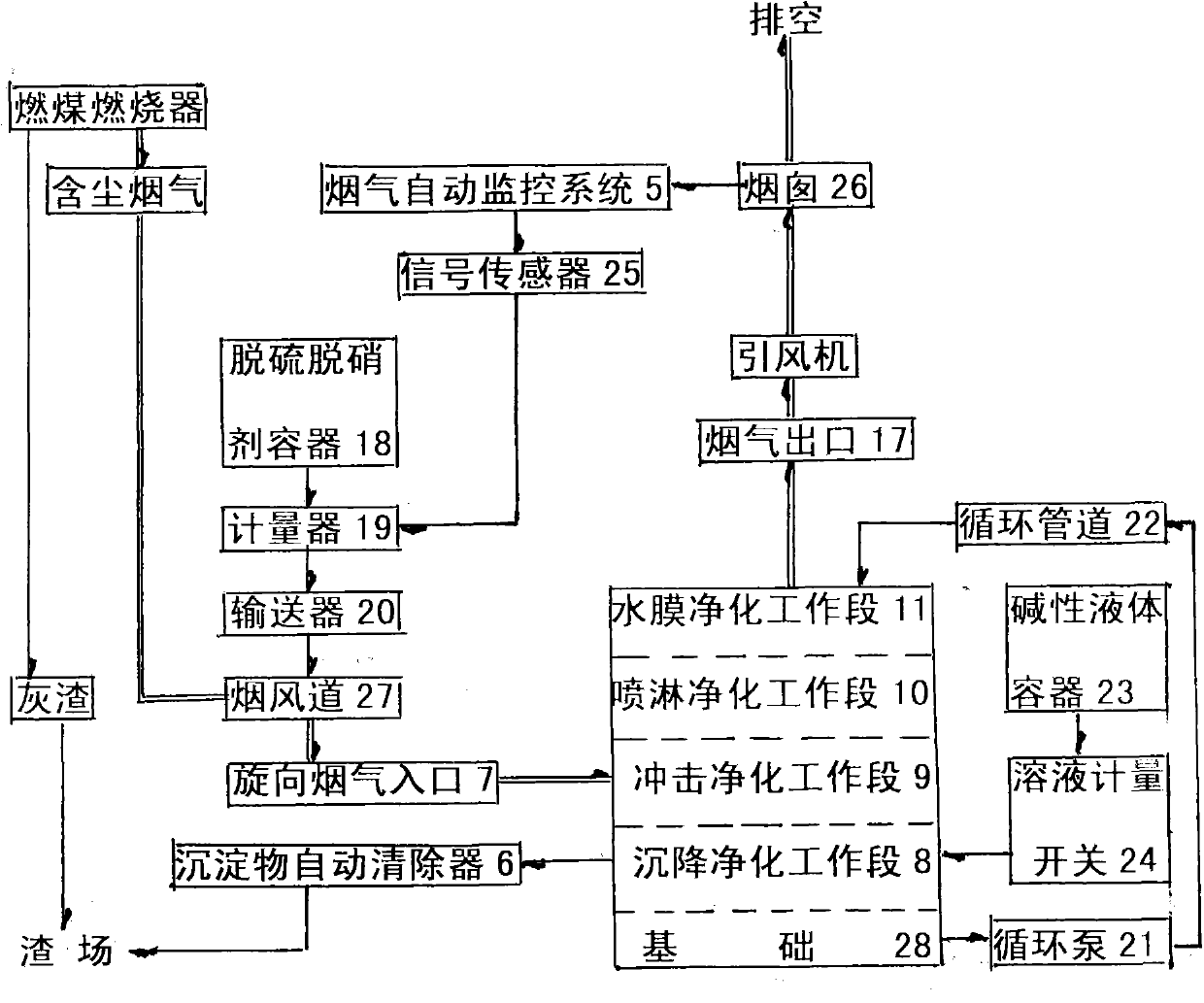

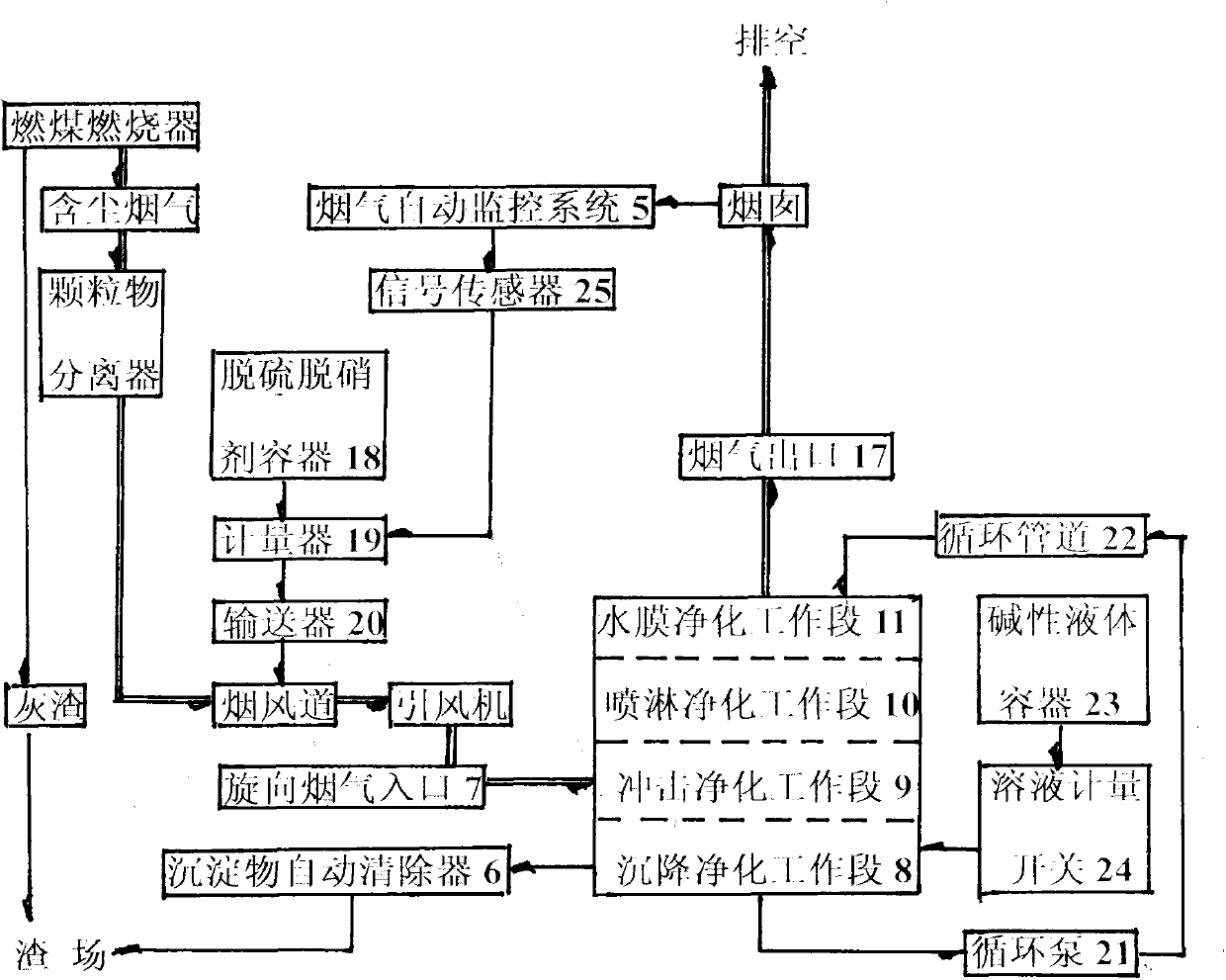

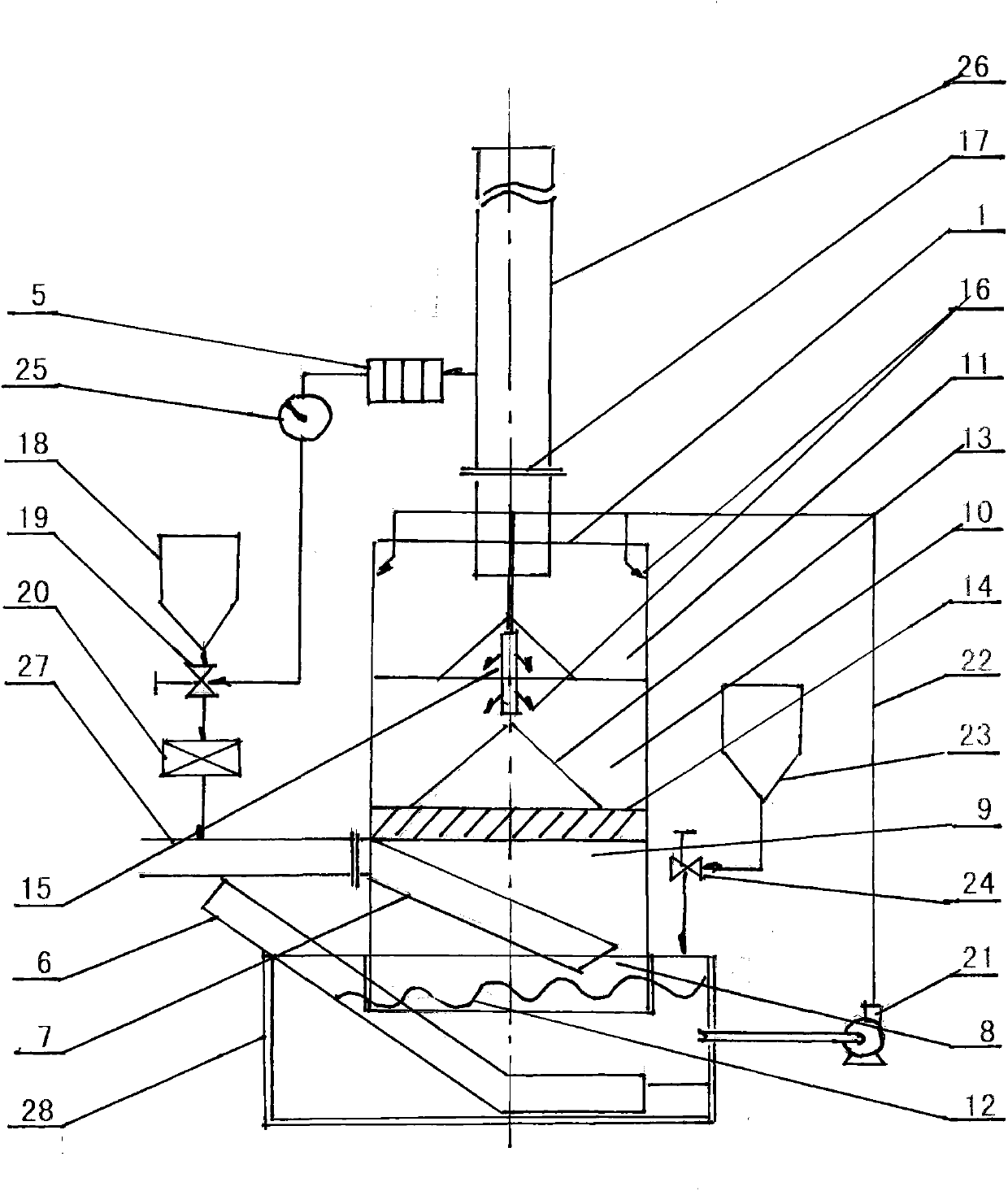

[0025] figure 1 It is a block diagram of the principle work flow of the suction type installation and purification of the embodiment, combined with figure 1We can see that the dusty acid flue gas produced by the coal burner, together with the powdered active desulfurization and denitrification agent sprayed into the desulfurization and denitration agent container 18 through the meter 19 and the conveyor 20, is passed through the flue air duct 27. Introduce the swirling flue gas inlet 7. During this process, after the acidic pollutants in the flue gas are mixed with the powdery active desulfurization and denitrification agent, a preliminary chemical reaction pretreatment is carried out. The pretreated flue gas is discharged in the combined purification tower The rotating air flow is generated in the cylindrical cavity of 1, which impacts the partial alkaline liquid 12 located in the sedimentation and purification working section 8 downwards, forming a mixed steam-water flow and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com