Grinding wheel angle correcting device for cylindrical grinding machine and grinding wheel angle correcting method

An angle correction, cylindrical grinding machine technology, applied in the direction of abrasive surface adjustment device, grinding machine parts, grinding/polishing equipment, etc. Achieve the effect of improving product quality and production efficiency, avoiding safety accidents, and saving processing cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1 A Grinding Wheel Angle Correction Device for Cylindrical Grinding Machines

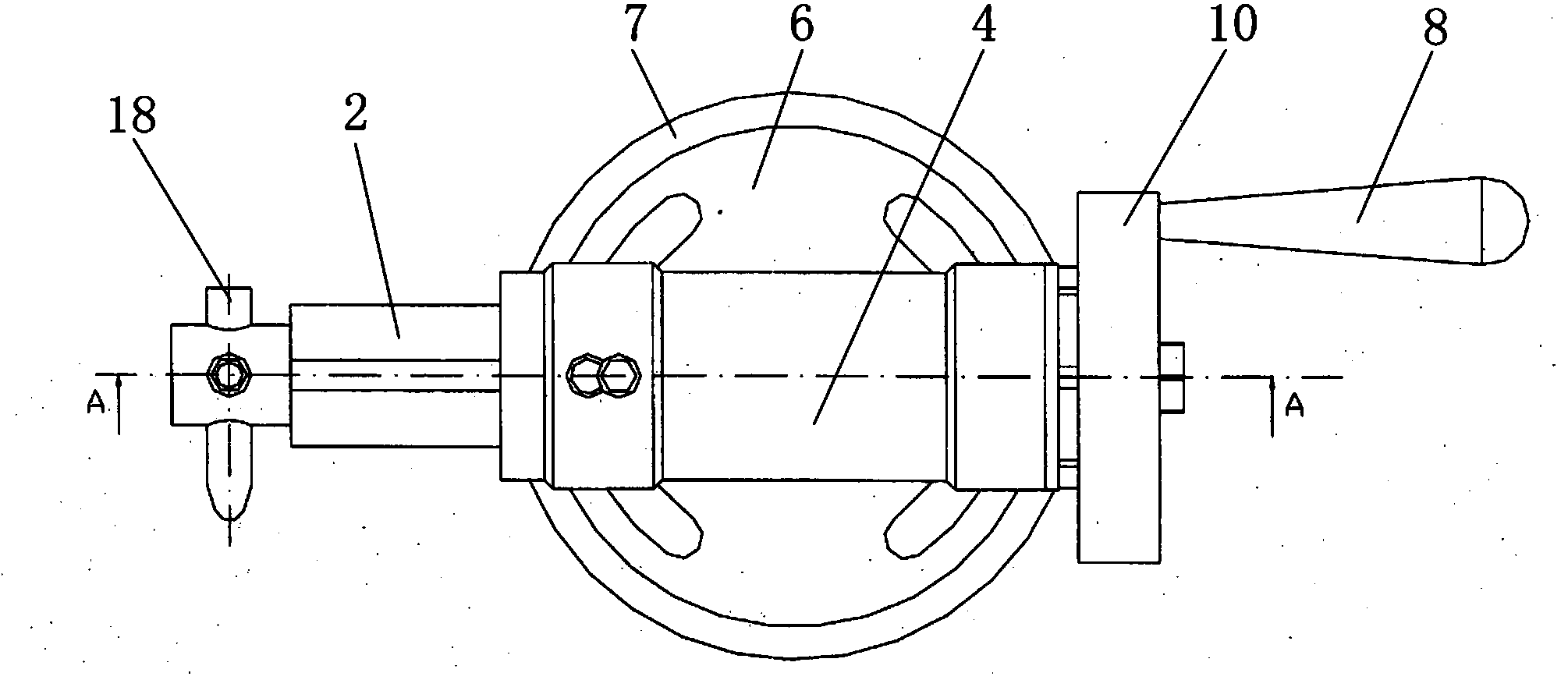

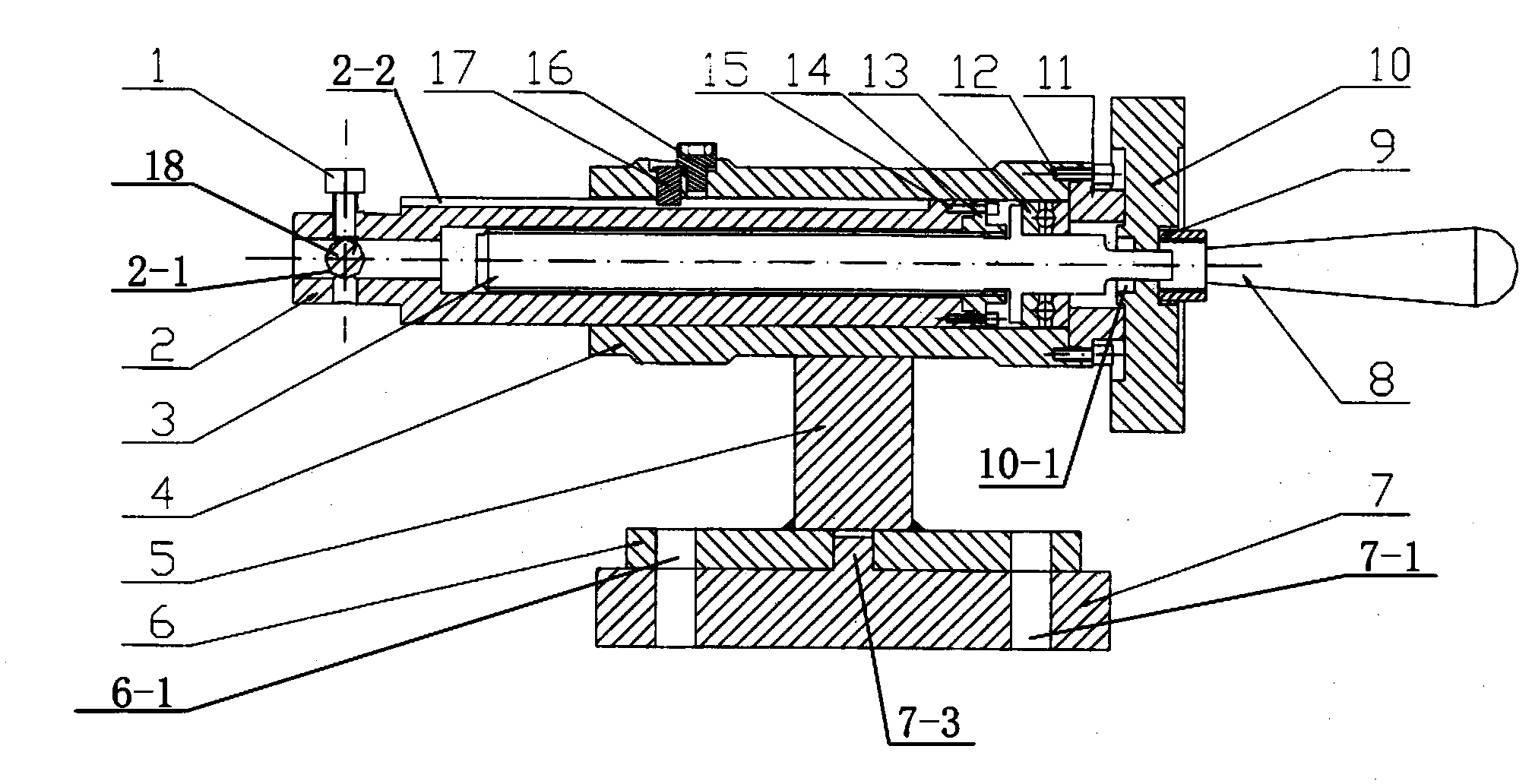

[0016] Such as Figure 1-Figure 3 As shown, a grinding wheel angle correction device for a cylindrical grinder is composed of a main body component, a moving component, a transmission component and a diamond pen (18).

[0017] The outer cylinder (4), the outer end cover (11), the bracket (5), the angle plate (6) and the scale plate (7) constitute the main component.

[0018] The fixed bolt I (1), the sleeve (2) and the inner end cover (14) constitute a moving component.

[0019] Lead screw shaft (3), end face bearing (13), handle (8), fixed nut (9) and rocking wheel (10) constitute transmission member.

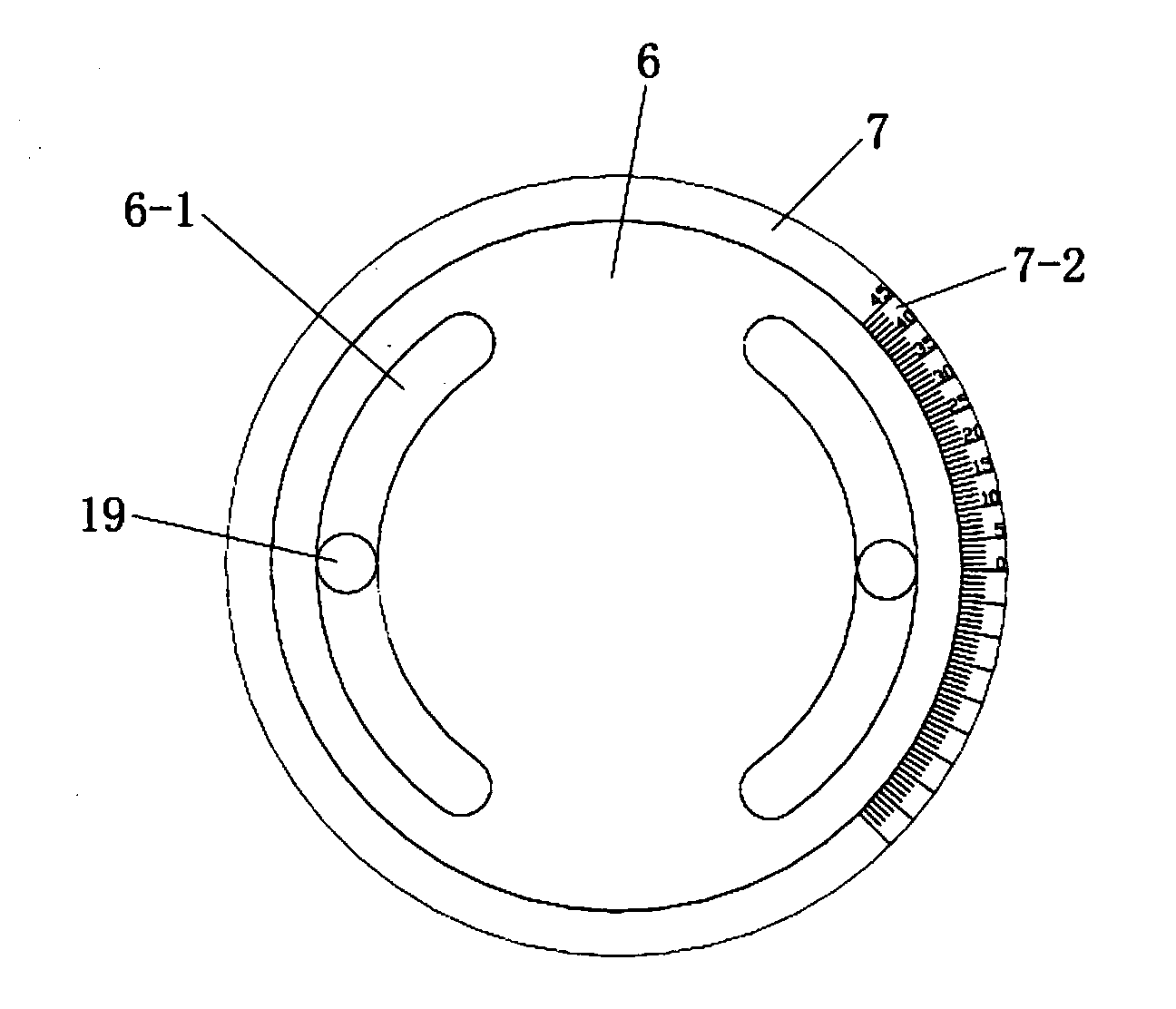

[0020] The main component is: the center of the scale plate (7) is provided with a cylindrical pin (7-3), and the scale plate (7) is inserted into the hole in the center of the angle plate (6) through the cylinder pin (7-3) and positioned with the angle plate (6) , the angle plate ...

Embodiment 2

[0024] Embodiment 2 A grinding wheel angle correction method

[0025] Using the grinding wheel angle correction device for the cylindrical grinder of Example 1, the method is as follows: insert the diamond pen (18) into the correction hole (2-1) of the sleeve (2), and fix it by the fixing bolt I (1). Install and fix the scale plate (7) on the machine tool, first loosen the positioning pin (19), turn the angle plate (6) according to the angle requirements, and align it with the corresponding scale on the scale plate (7), and then pass the positioning pin (19) Fix the angle plate (6) and the scale plate (7); shake the handle (8) to drive the rocking wheel (10) to rotate, and the rocking wheel (10) drives the screw shaft (3) to rotate, and the screw shaft (3) ) rotates to drive the inner end cover (14) and the sleeve (2) to move back and forth, and the stop pin (17) cooperates with the positioning groove II (2-2) of the sleeve (2) to prevent the sleeve (2) from moving forward and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com