Mould-less large-caliber PVC pipe dynamic molding method and device

A PVC pipe, dynamic forming technology, applied in the direction of tubular goods, household appliances, other household appliances, etc., can solve the problems of complex equipment, high cost, complex process, etc., to achieve fast welding, avoid PVC degradation, and improve the effect of forming efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

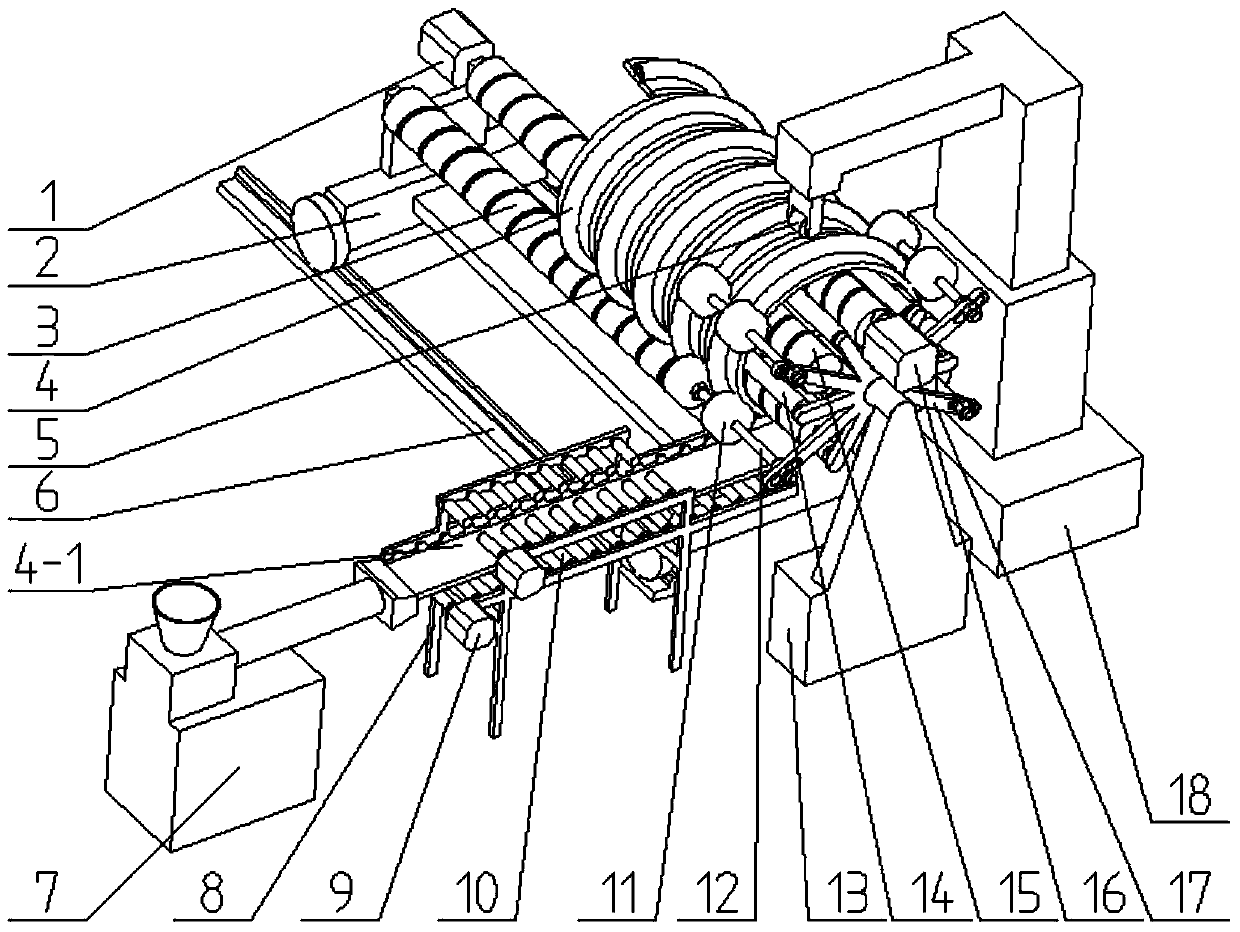

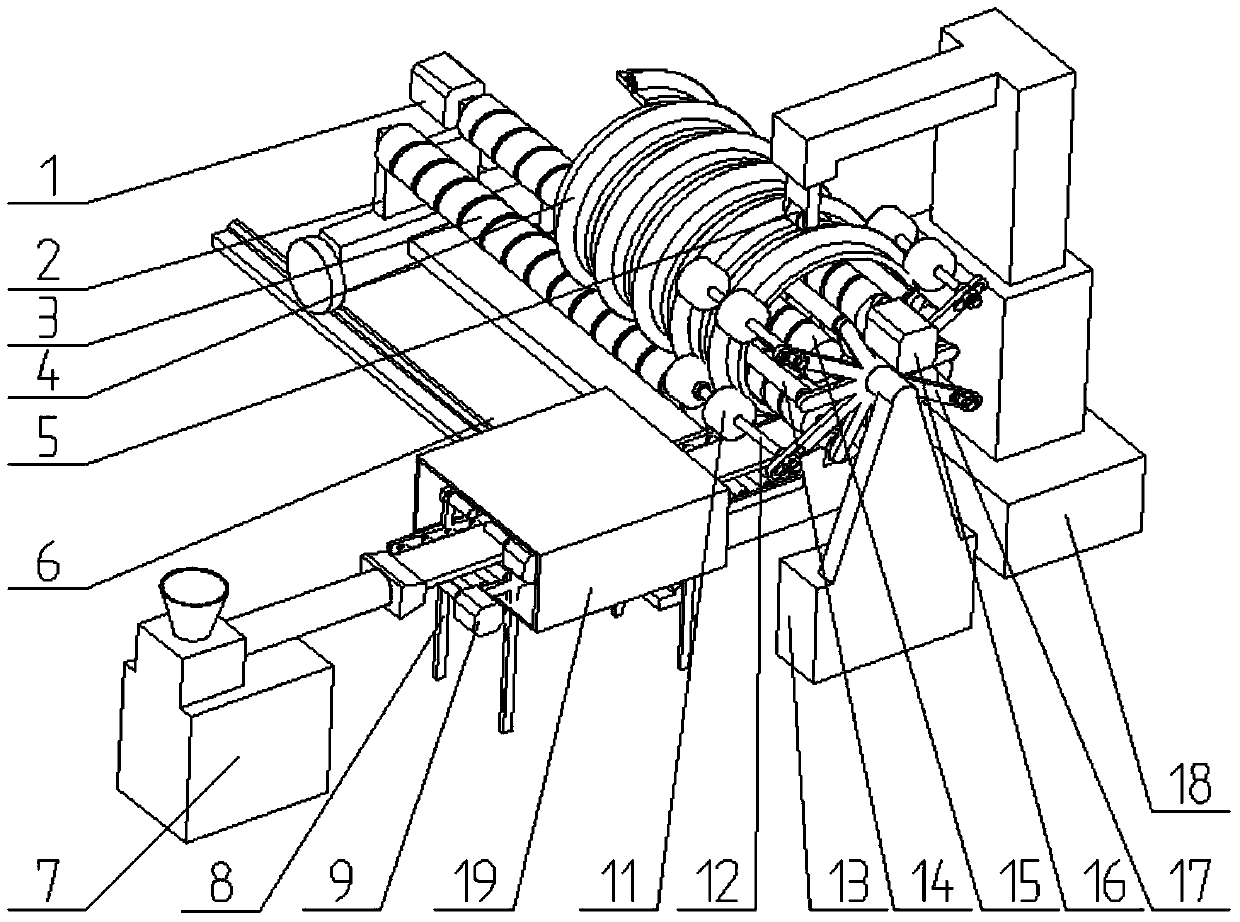

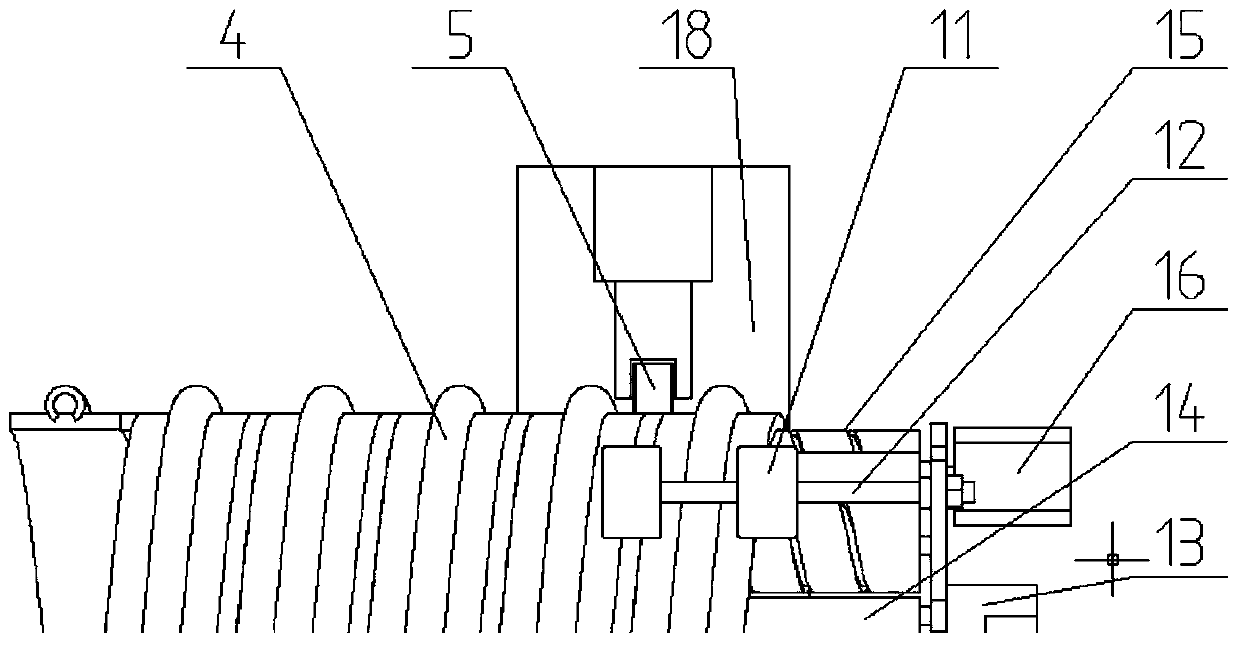

[0031] The purpose of the present invention is to design a method and device for dynamic forming of large-diameter PVC pipes without molds for the deficiencies in the prior art, such as complex equipment, high cost, and complicated processes. The ultrasonic welding device 18 is used to perform gap welding of PVC pipes 4. The welding head 5 is a rollable cylinder. The welding head 5 is pressed on the PVC sheet 4-1 and rotates with the roller 15 to realize extrusion, winding and welding simultaneously. When winding a circle of Ω-shaped PVC sheet, ultrasonic waves The welding device 18 melts and welds the upper circle of Ω-shaped PVC sheet 4-1, and the formed PVC pipe 4 is caught by the pipe support frame 2, which can realize dynamic welding and continuous production, which not only simplifies the device, but also greatly Greatly improve the forming efficiency of large-diameter PVC pipes.

[0032] The present invention is a dynamic molding device for large-diameter PVC pipes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com