Reinforcement and desalination method for crisp powder ceramic painted cultural relic

A ceramic and painted technology, applied in the field of restoration of cultural relics, can solve the problems of unfavorable long-term preservation of cultural relics, and achieve the effect of good fluidity and comprehensive penetration and reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

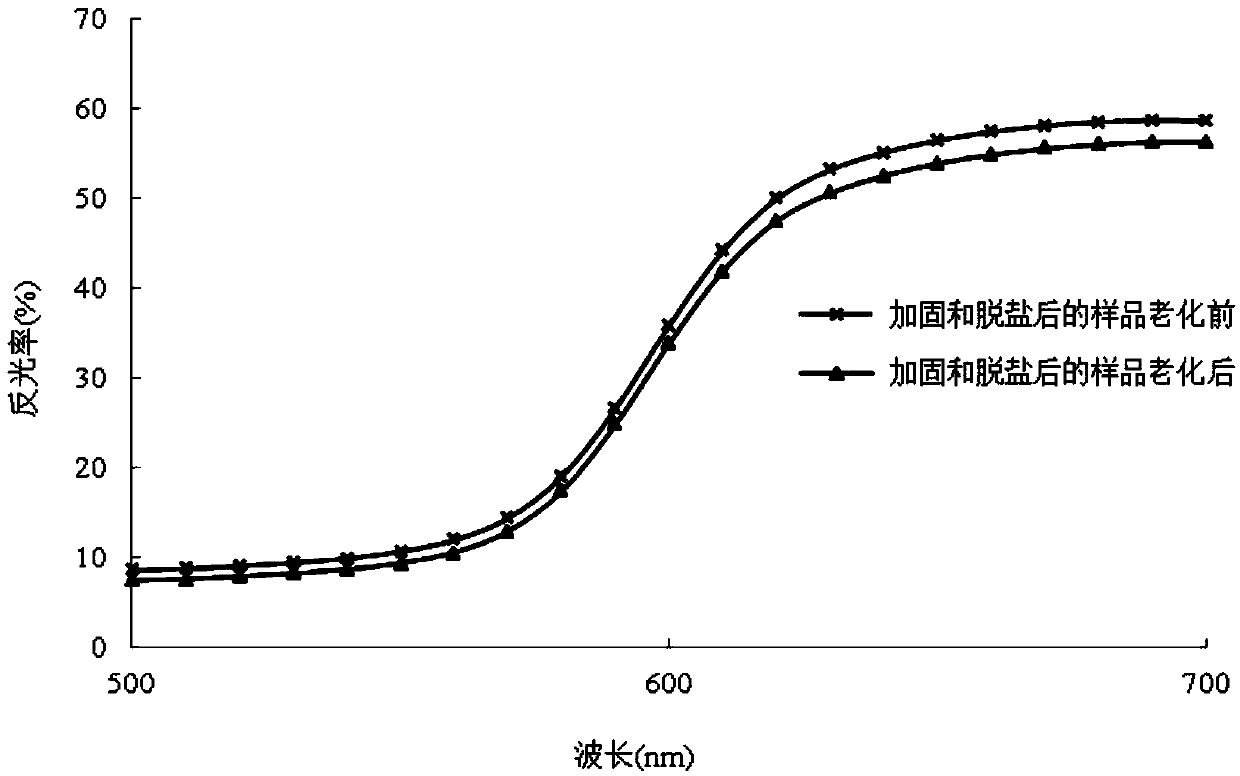

Embodiment 1

[0040] 1. Moistening crisp powder pottery painted cultural relics

[0041] Use a dropper to absorb methanol, and slowly add methanol dropwise on the surface of the crispy powder ceramic painted cultural relics until the entire surface of the crispy powder ceramic painted cultural relics is completely wetted.

[0042] 2. Preparation of reinforcing agent

[0043] Prepare the reinforcing agent according to the mass ratio of the following raw materials:

[0044]

[0045]

[0046] 3. Crisp powder pre-reinforcement

[0047] Use a 5.0mL syringe to draw 2.5mL of the reinforcing agent prepared in step 2, and drop it on the surface of the ceramic painted cultural relics that was completely wetted in step 1. After the surface is completely air-dried, dip the twice-diluted reinforcing agent with absorbent cotton and apply it On the surface of ceramic painted cultural relics, smear repeatedly 3 to 5 times to obtain reinforced ceramic painted cultural relics.

[0048] 4. Preparatio...

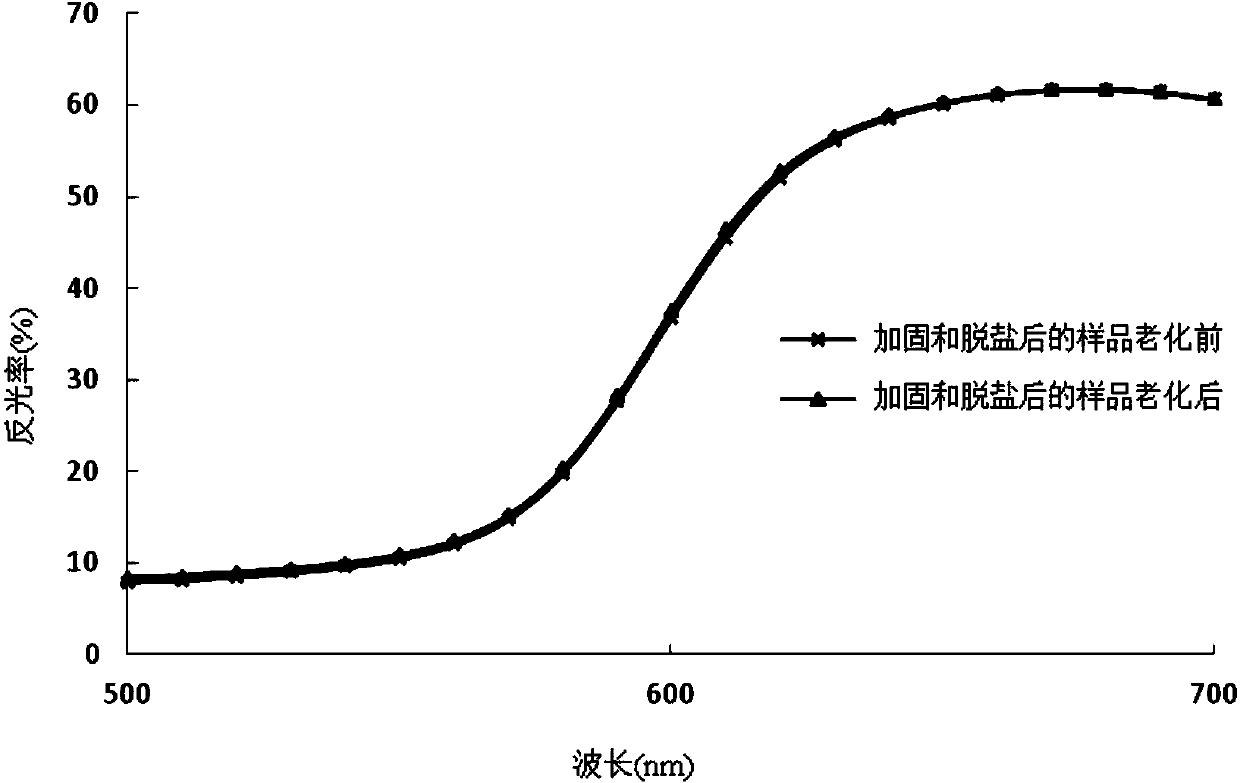

Embodiment 2

[0053] The reinforcing agent of the present embodiment is prepared according to the mass ratio of the following raw materials:

[0054]

[0055] Other steps are identical with embodiment 1.

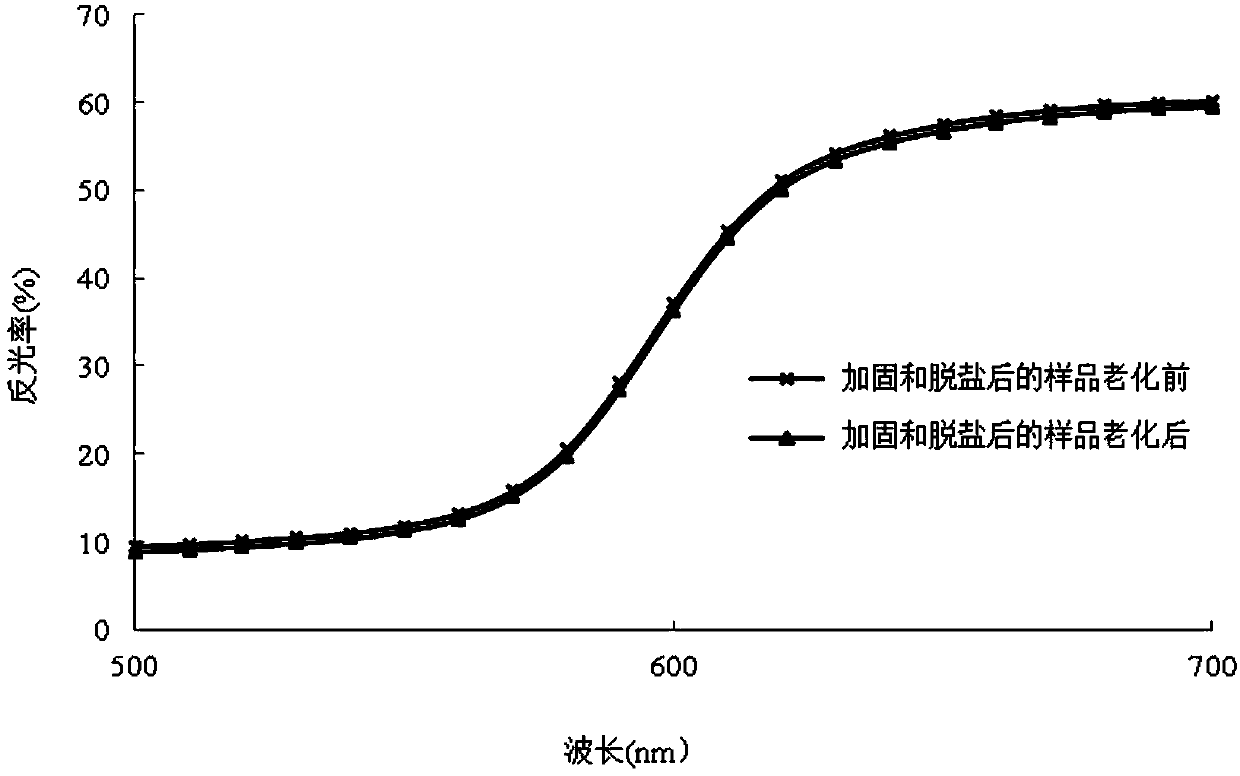

Embodiment 3

[0057] The reinforcing agent of the present embodiment is prepared according to the mass ratio of the following raw materials:

[0058]

[0059] Other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com