Production process for novel wood decorative board

A production process and decorative panel technology, which is applied in the production process of new wooden decorative panels, can solve the problems of low sound absorption performance, low plasticity, complicated installation, etc., and achieve the effects of good aging resistance, personalized color and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

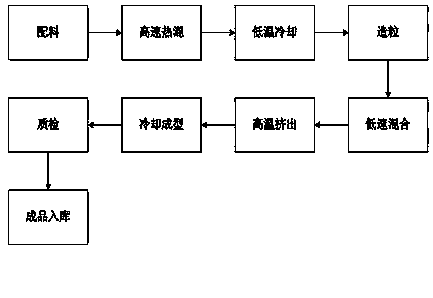

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] A kind of production technology of novel wooden decorative panel, such as figure 1 As shown, it includes batching, high-efficiency hot mixing, low-temperature cooling, granulation, low-speed mixing, high-temperature extrusion, cooling molding, and quality inspection. Then start granulation, then enter into low-speed mixing and high-temperature extrusion, cooling and forming, and finally quality inspection.

[0014] The ingredients are composed of PVC resin, wood powder, natural calcium powder and chemical additives.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com