Hypoeutectic high-chromium white cast iron roller and preparation method thereof

A high-chromium white cast iron and hypoeutectic technology, applied in the field of rolls and preparation, can solve the problems of low thermal fatigue resistance, affecting the quality of the rolled piece, and large hardness drop, so as to improve thermal fatigue properties, solve cracks and dropouts block, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

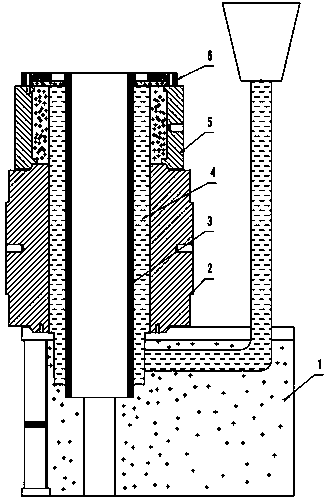

Image

Examples

Embodiment 1

[0030] Example 1: C 2.1%; Si 0.6%; Mn 0.4%; Cr 21.4%; Mo 1.41%; Ni1.57%; B 0.3%; Ti 0.15; W 0.2%; Nb 0.13% V 0.26%; 0.3%; S 0.021%, P 0.022%; the balance is Fe.

Embodiment 2

[0031] Example 2: C 2.2%; Si 0.5; Mn 0.34%; Cr 23%; Mo 1.3%; Ni1.66%; B 0.5%; Ti 0.18; W 0.25%; Nb 0.2% V 0.23%; %; S 0.013%, P 0.018%; the balance is Fe.

Embodiment 3

[0032]Example 3: C 2.29%; Si 0.71%; Mn 0.3%; Cr 22.3%; Mo 1.2%; Ni1.78%; B 0.55%; Ti 0.2; W 0.23%; Nb 0.16% V 0.2%; 0.35%; S 0.14%, P 0.015%; the balance is Fe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Impact toughness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com