Rotating inclined disc type compressor

A swash plate and compressor technology, applied in the field of compressors, can solve the problems of reducing discharge pressure, increasing compressor power consumption, pressure imbalance, etc., and achieving the effects of reducing noise, reducing pulsation, and reducing pulsating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

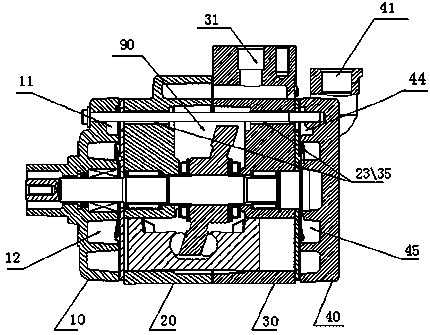

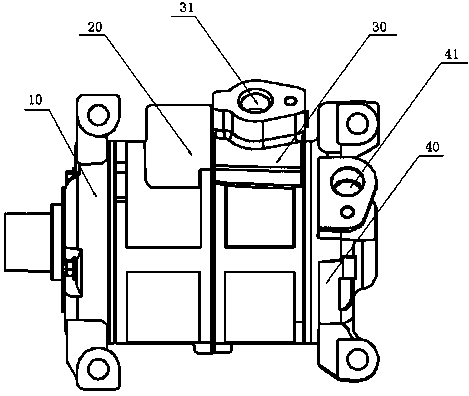

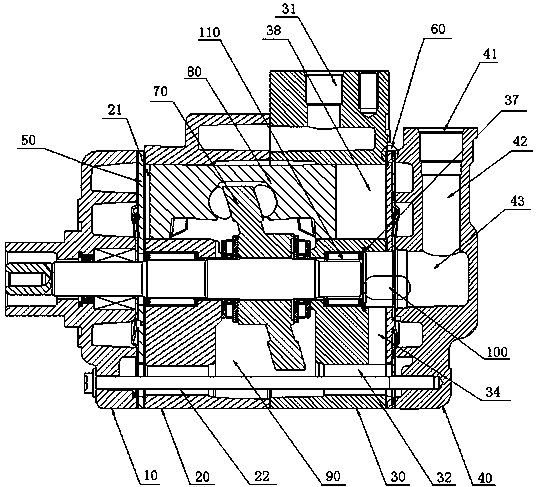

[0042] like figure 2 , 3 As shown, a suction device of a swash plate compressor includes a front cylinder 20, a rear cylinder 30 and a crank chamber 90 connected to each other, and a front cylinder head 10 and a rear cylinder for closing the ends of the front and rear cylinders. Cover 40, the front cylinder head 10 is connected with the front cylinder 20 through the front valve plate 50, the rear cylinder 30 is connected with the rear cylinder head 40 through the rear valve plate 60; The refrigerant suction port 41 on the outer surface of the rear cylinder head 40 . The swash plate 70, the bearing 110 and the piston 80 are arranged in the front and rear cylinders.

[0043]Preferably, the air intake stabilizing area 100 is formed inside the connection between the rear cylinder head 40 and the rear cylinder 30 .

[0044] The second situation is that the structure is the same as above, except that the exhaust port 31 of the refrigerant is located on the outer surface of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com