Multi-motor drive built-in valve for large-flow gas meter

A multi-motor-driven, gas meter technology, applied to devices for pressure relief on sealing surfaces, valve operation/release devices, valve details, etc., can solve problems such as inconvenience in operation and use, and achieve convenient and convenient opening Open, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

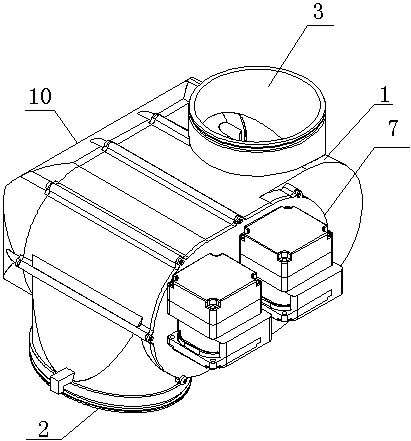

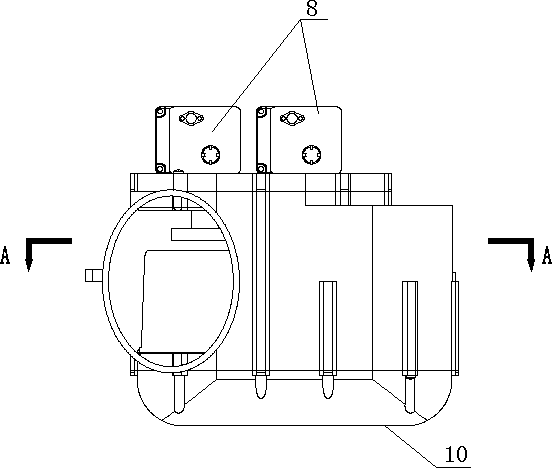

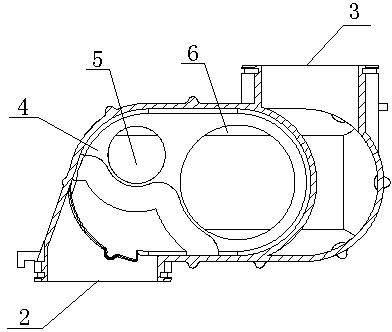

[0016] Such as Figure 1-6 As shown, the present invention includes a valve body 1, the valve body 1 is provided with an air inlet 2 and an air outlet 3, and the valve body 1 is provided with a partition plate 4 between the air inlet 2 and the air outlet 3, It is characterized in that: a pressure relief hole 5 and an air passage 6 are opened on the partition plate 4, the diameter of the pressure relief hole 5 is smaller than the diameter of the air passage 6, and an opening opposite to the partition plate 4 is provided on the valve body 1. The valve body 1 is provided with an end cover 7 capable of sealing the opening, and a valve controller with the same number of pressure relief holes 5 and air passage holes 6 is installed on the end cover 7. The valve controller includes a motor control part 8 and The valve seal 9 that can seal the pressure relief hole 5 and the air passage hole 6, the motor control part 8 on the valve controller is located outside the valve body 1, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com