Automotive paint system pipeline access door

A technology for repairing doors and pipelines, which is applied in the direction of pipeline protection, pipeline protection through heat insulation, fire doors, etc., which can solve the problems of complex manufacturing process and door frame penetration of cold, and achieve the effect of simple manufacturing process, low cost, and solution of penetration of cold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings, so as to have a further understanding of the concept of the present invention, the technical problems to be solved, the technical features constituting the technical solution, and the technical effects brought about.

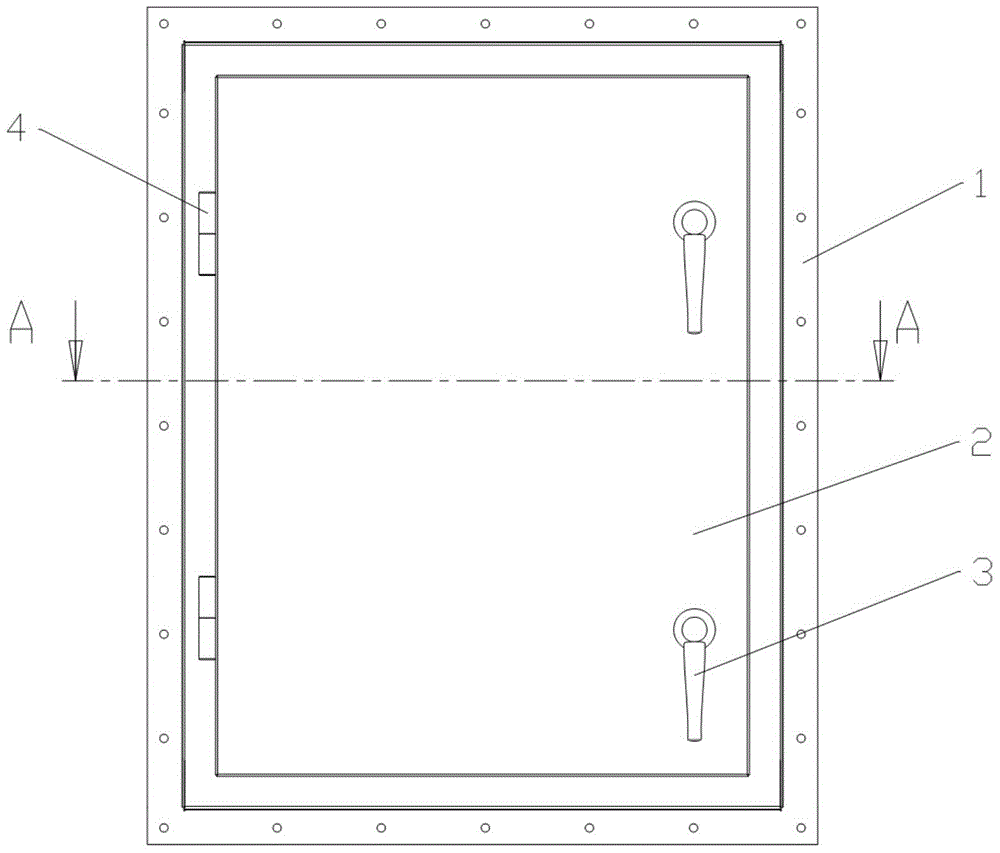

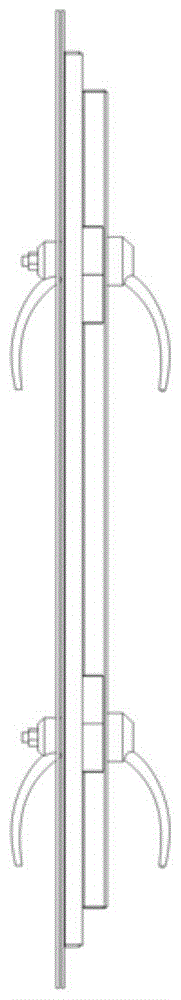

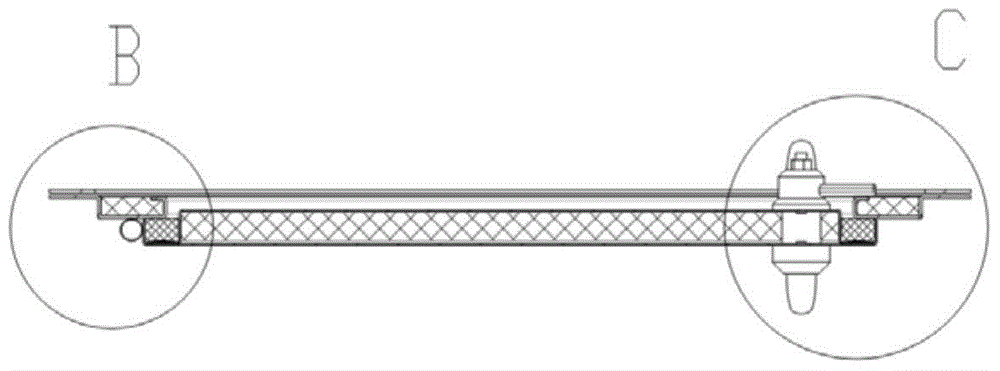

[0020] like Figure 1-10 The pipeline maintenance door of the automobile painting system shown includes a thermal insulation door frame 1, a thermal insulation door 2, a handle lock 3, and a door shaft combination 4, wherein the thermal insulation door frame 1 is made of 2.5mm galvanized sheet, and the thermal insulation door 2 is made of 1.5mm galvanized sheet , the thermal insulation door frame 1 and the thermal insulation door 2 are connected through the door shaft combination 4, the door shaft combination 4 is composed of the door shaft convex 41 and the door shaft concave 42, which is a rotating fitting, the door shaft conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com