LED heat radiation structure formed by mixing heat conducting insulation powder and resin and LED linear lamp

A LED linear lamp, heat conduction and insulation technology, applied in the direction of lampshade, lighting and heating equipment, components of lighting devices, etc., can solve the problems of insufficient heat dissipation, low efficiency, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A specific embodiment of an LED linear lamp with an LED heat dissipation structure mixed with thermally conductive insulating powder and resin will be described in more detail below.

[0031] However, those skilled in the art should understand that the following are only examples and descriptions of some preferred implementations, and other similar or equivalent implementations can also be used to implement the present invention.

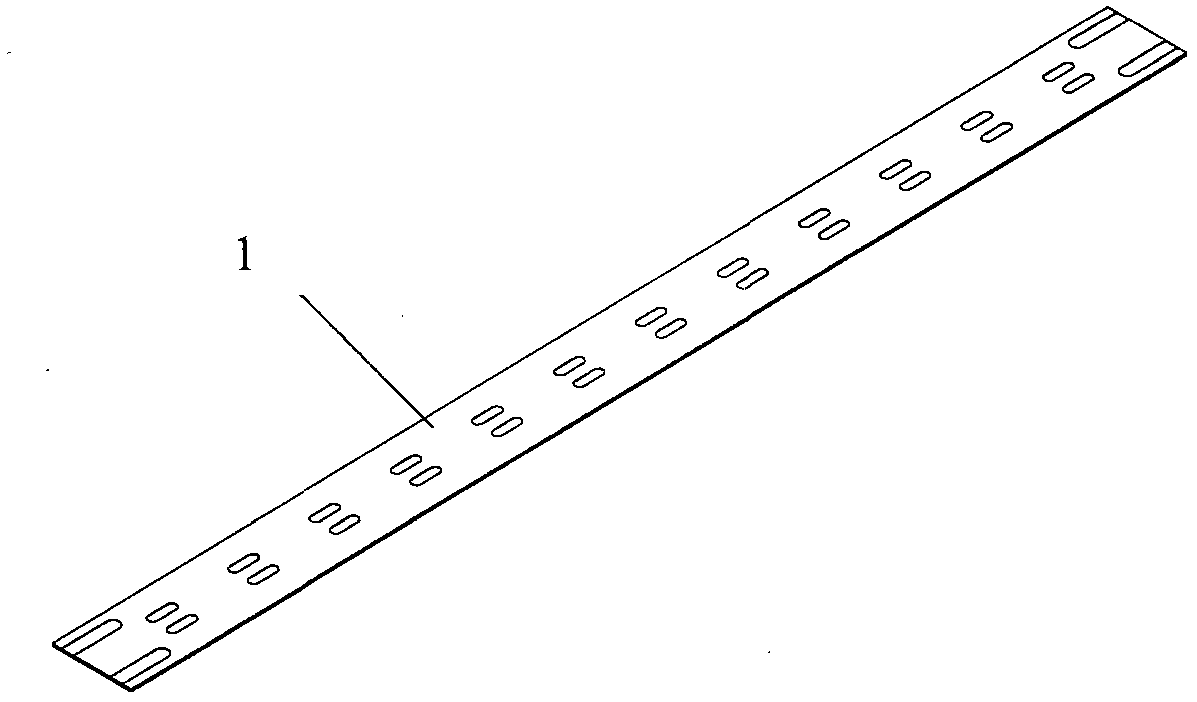

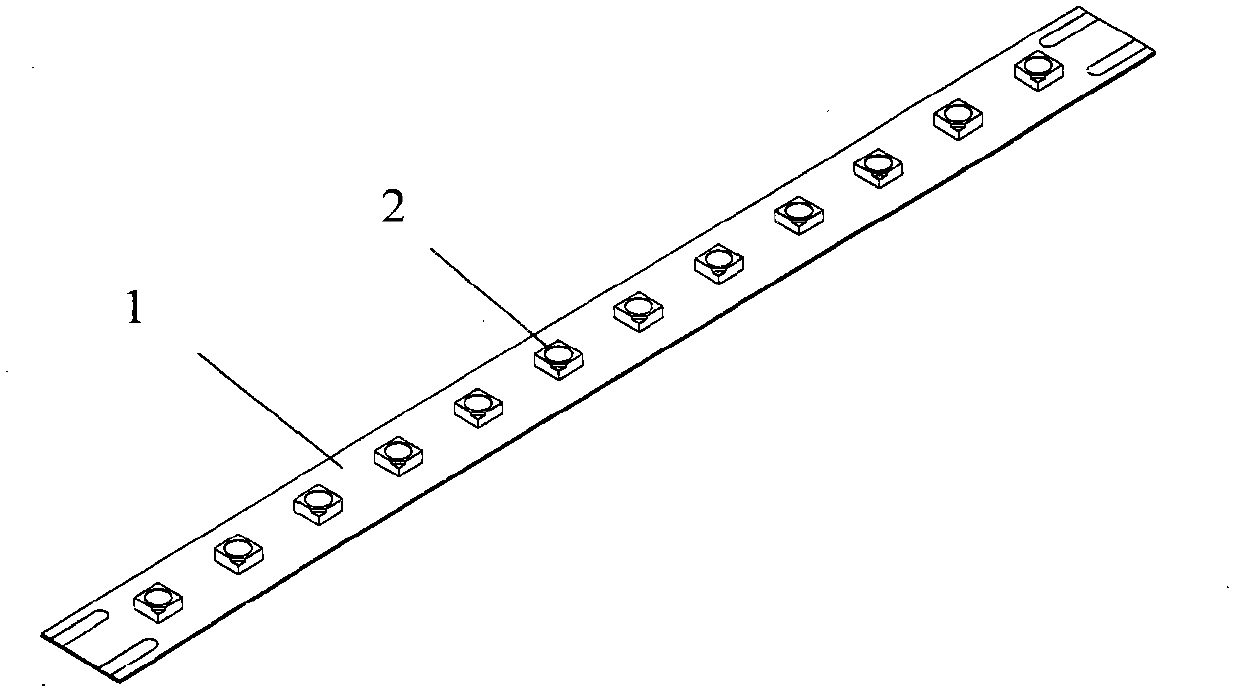

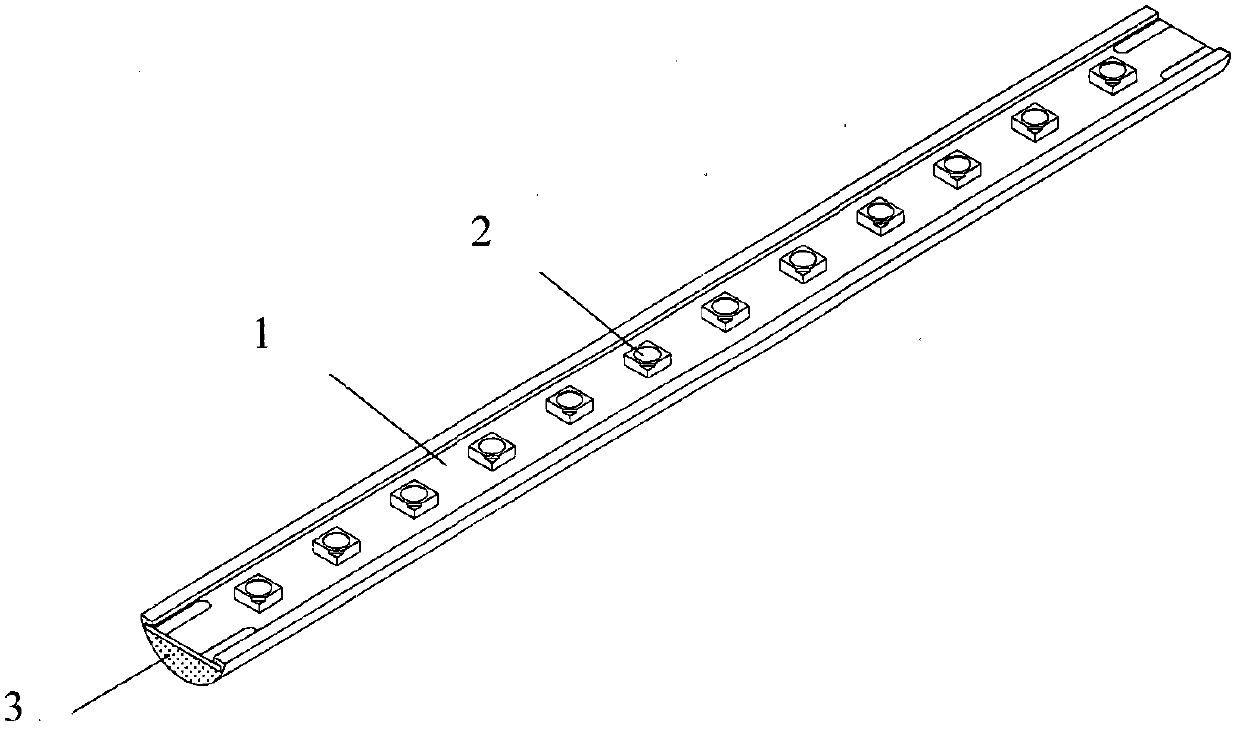

[0032] For example: will be as figure 1 As shown in the LED light source module circuit board (1), the LED lamp (2) is welded on the circuit board (1) through the traditional SMT mounting and welding process (such as figure 2 shown).

[0033] For example, 48% of alumina powder and 52% of PVC rubber are uniformly mixed, and additives are added to knead to form granular high thermal conductivity material 3 .

[0034] Use an extruder to extrude the high thermal conductivity material and the LED circuit board light source module together, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com