Gas water heater integrated stainless steel heat exchanger

A gas water heater, stainless steel technology, applied in the direction of heat exchanger shell, fluid heater, heat exchange equipment, etc., can solve the problems of complex heat exchanger processing, poor welding quality, easy scaling, etc., to avoid the rise of water temperature The effects of too fast, high welding quality, and reduced water temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

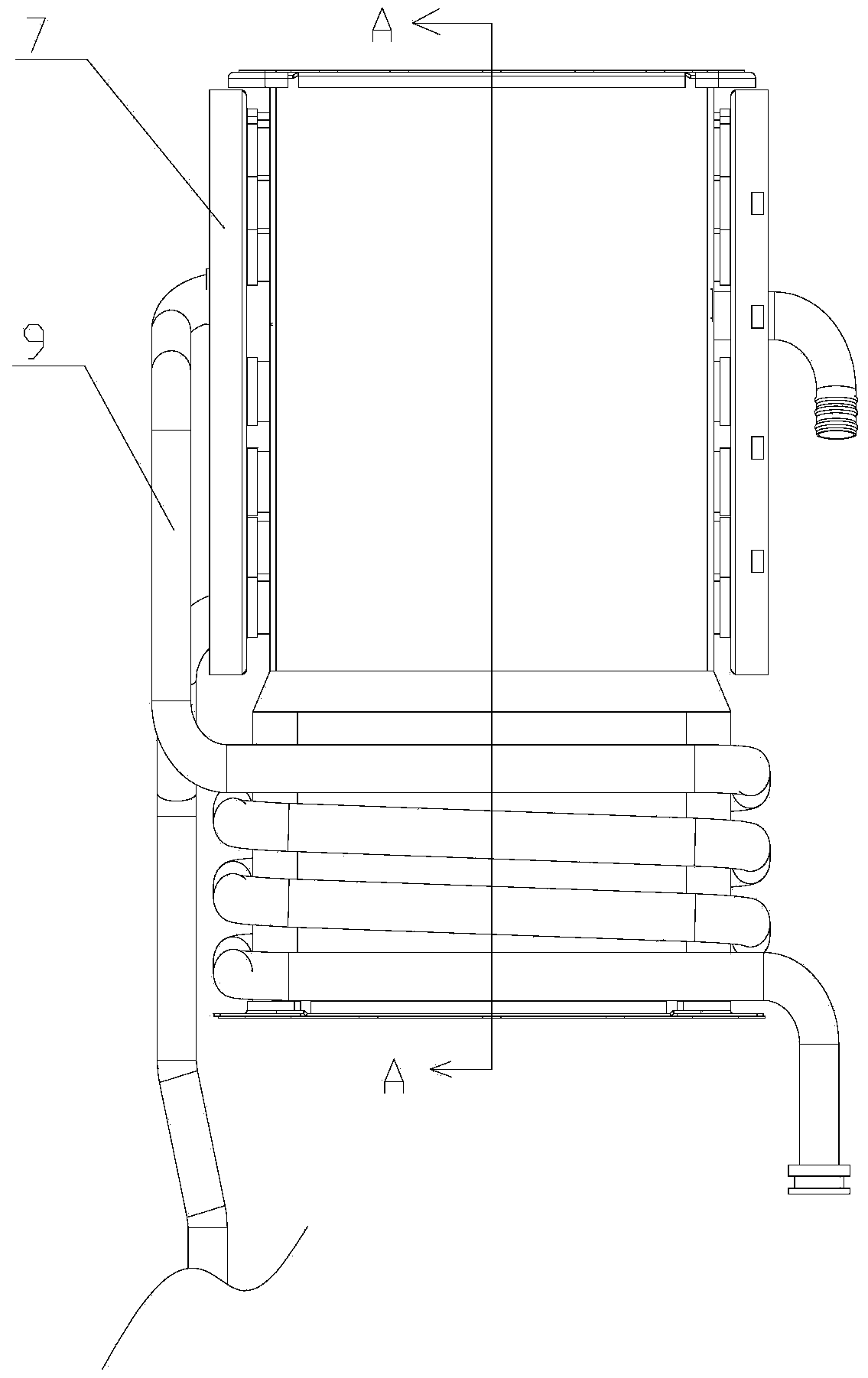

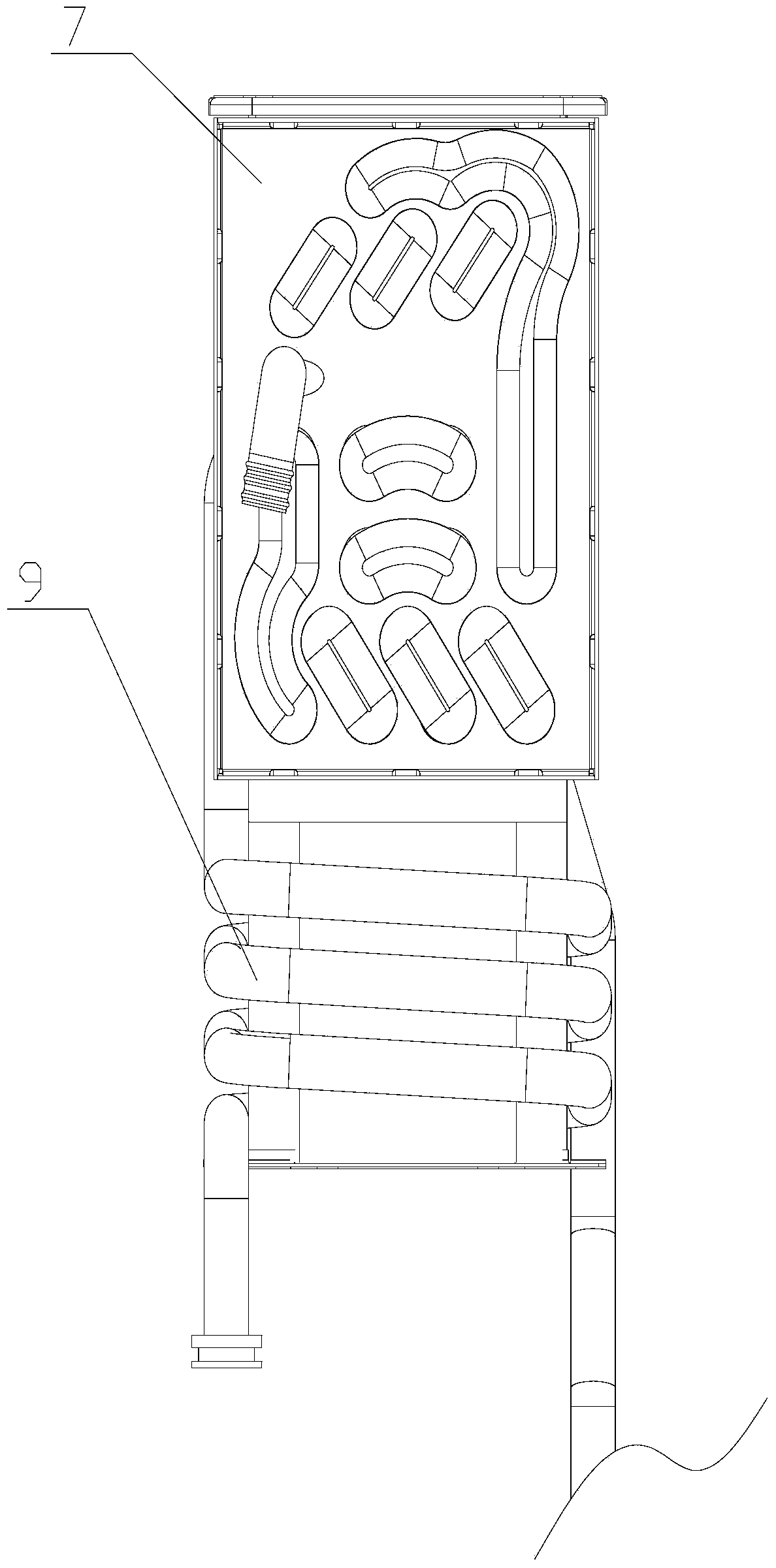

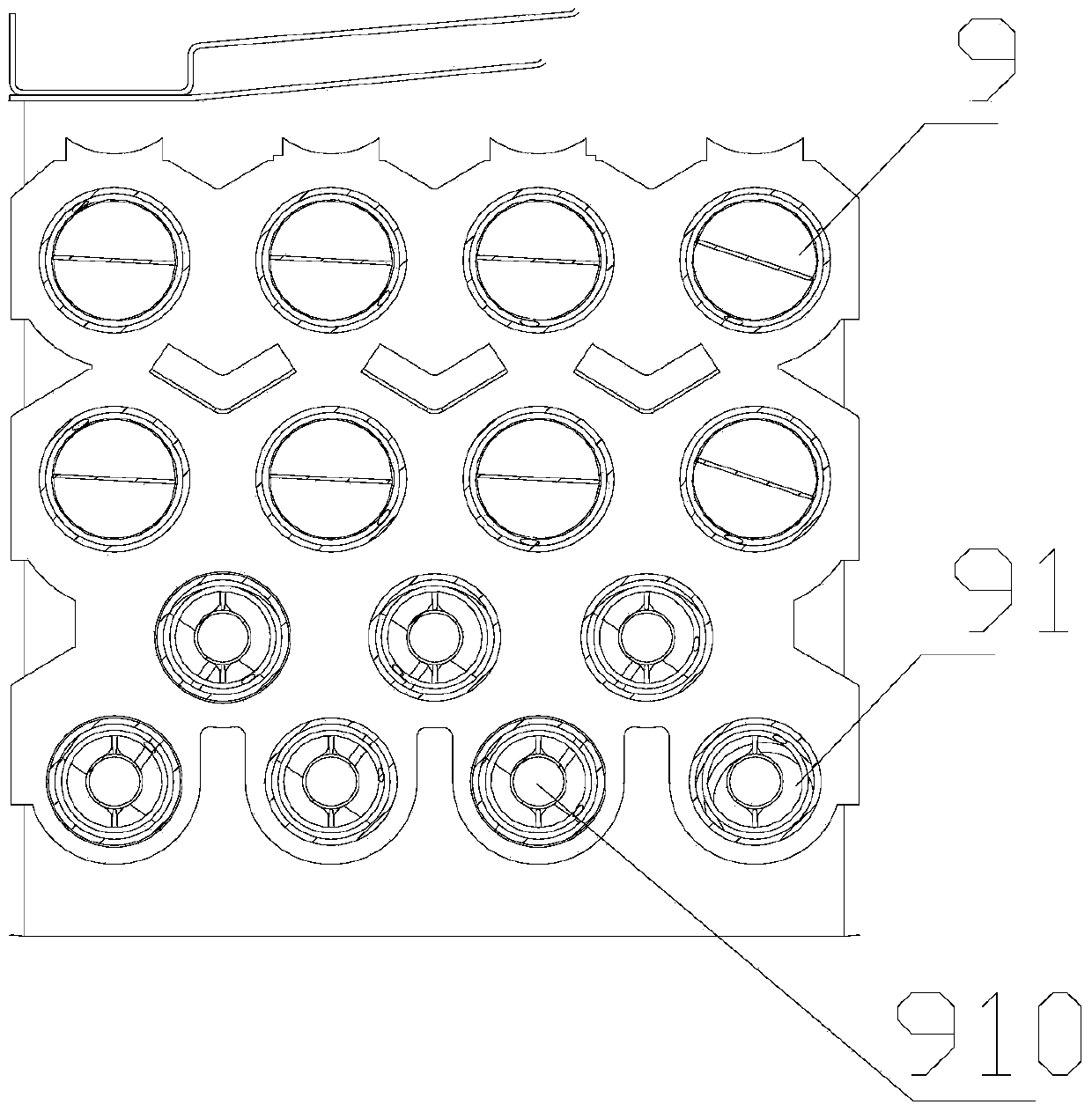

[0035] Such as figure 1 , Figure 10 and figure 2 As shown, the gas water heater integrated stainless steel heat exchanger of the embodiment of the present invention includes: a surrounding frame 1 and a plurality of heat exchange tubes 9 passing through the surrounding frame 1, and the heat exchange tubes 9 passing through the surrounding frame 1 A water collection box 7 is provided at the end of the tube, and the water collection box 7 connects each of the heat exchange tubes 9 into a continuous flow channel; at least one row of the heat exchange tubes 91 adjacent to the heating zone is provided with a strip-shaped Part 910, the heat exchange tubes 91 are the row of heat exchange tubes closest to the heating area or burner, and the heat exchange tubes in this are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com