Traditional Chinese medicine composition for curing fractures and osteoporosis and preparation method and application thereof

A technology for treating osteoporosis and fractures, applied in drug combinations, pharmaceutical formulas, medical preparations containing active ingredients, etc., can solve the problems of not being able to relieve pain in time, not being able to obtain therapeutic effects, etc., and achieve no toxic side effects and low price , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

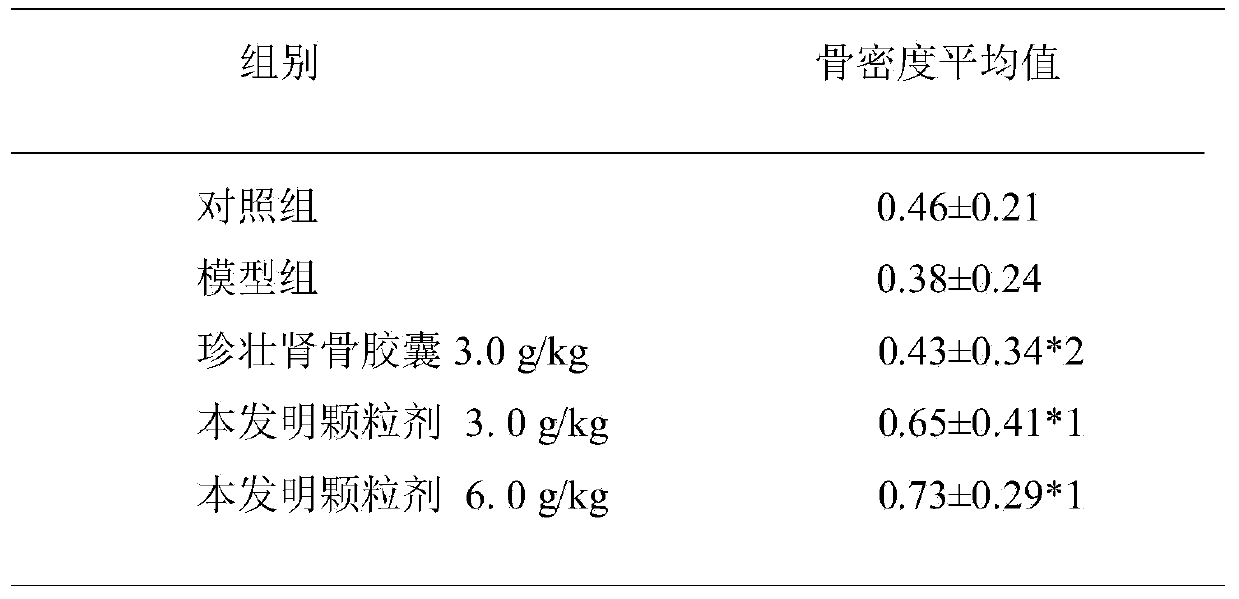

Image

Examples

Embodiment 1

[0016] Example 1: Take 20g caviar, 25g purple larkspur, 15g euphratica, 10g ginseng, 15g selaginella, 8g selaginella, 10g deer jelly, 15g epimedium, 10g calamus, and 20g scallion, add water Decoct twice, add water to 10 times the weight of the medicinal materials, decoct for 2 hours, combine the decoctions, concentrate under reduced pressure to an extract with a relative density of 1.15 at 65°C, add ethanol so that the volume percentage of the alcohol content reaches 75%, Stir, stand still, filter, and the relative density of the filtrate is 1.25 when the filtrate is concentrated under reduced pressure to 65°C, and the ethanol is recovered to obtain a concentrated solution, which is prepared into an oral liquid by adding water and auxiliary materials, or the concentrated solution is spray-dried. The spray-drying conditions are: : The inlet air temperature is 110°C, the outlet air temperature is 85°C, the material temperature is 70°C, the atomization pressure is 0.2 MPa, the spr...

Embodiment 2

[0017] Example 2: Take 20g caviar, 25g purple larkspur, 15g euphratica, 10g ginseng, 15g selaginella, 8g selaginella, 10g deer jelly, 15g epimedium, 10g calamus, and 20g scallion, and add water Decoct twice, add water to 10 times the weight of the medicinal materials, decoct for 2 hours, combine the decoctions, concentrate under reduced pressure to an extract with a relative density of 1.15 at 65°C, add ethanol so that the volume percentage of the alcohol content reaches 75%, Stir, stand still, filter, and the relative density of the filtrate is 1.25 when the filtrate is concentrated under reduced pressure to 65°C, and the ethanol is recovered to obtain a concentrated solution, which is prepared into an oral liquid by adding water and auxiliary materials, or the concentrated solution is spray-dried. The spray-drying conditions are: : The inlet air temperature is 110°C, the outlet air temperature is 85°C, the material temperature is 70°C, the atomization pressure is 0.2 MPa, the...

Embodiment 3

[0018] Example 3: Take Caviar 20g, Larkspur 25g, Eupatorium 15g, Ginseng 10g, Selaginella 15g, Selaginella 8g, Grass jelly 10g, Epimedium 15g, Calamus 10g, Allium scallops 20g and combine, add water Decoct twice, add water to 10 times the weight of the medicinal materials, decoct for 2 hours, combine the decoctions, concentrate under reduced pressure to an extract with a relative density of 1.15 at 65°C, add ethanol so that the volume percentage of the alcohol content reaches 75%, Stir, stand still, filter, and the relative density of the filtrate is 1.25 when the filtrate is concentrated under reduced pressure to 65°C, and the ethanol is recovered to obtain a concentrated solution, which is prepared into an oral liquid by adding water and auxiliary materials, or the concentrated solution is spray-dried. The spray-drying conditions are: : The air inlet temperature is 110°C, the air outlet temperature is 85°C, the material temperature is 70°C, the atomization pressure is 0.2 MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com